Nominee 2005

Höchstleistungs-Röntgenstrahler

The innovative X-ray tubes developed by Peter Schardt, Karin Söldner, and Wolfgang Knüpfer form the basis. Peter Schardt heads the X-ray and Vacuum Innovation department at Siemens AG in Erlangen, Karin Söldner is project manager and responsible for Straton, Wolfgang Knüpfer is division manager for vacuum technology for X-ray tubes and image intensifiers.

Rapid rotation for sharp pictures

In computer tomography (CT), cross-sectional pictures of the body are taken using x-rays and joined to produce a 3D image, for example, of the heart. To obtain such detailed pictures of a beating heart, the x-ray source, an x-ray tube, must rotate very rapidly around the patient’s body. In this way, it produces many individual pictures with a very short exposure time. The technology used in conventional CT scanners, however, has come up against limiting factors.

more details

Resumes

Dr. rer. nat. Peter Schardt

- 20.06.1965

- geboren in Hadamar/Limburg-Weilburg

- 1985 – 1990

- Studium der Physik an der Technischen Universität

Darmstadt - 1990 – 1995

- Doktorand am Institut für Kernphysik,

Technische Universität Darmstadt - 1995

- Promotion

- 1995 – 1996

- Projektleitung für „Neue Röhrenprinzipien“ bei der

Siemens AG, Medical Solutions, Erlangen

- 1996 – 2000

- Projektleitung „Drehkolbenröhre für die medizinische

Diagnostik“ bei der Siemens AG, Medical Solutions,

Erlangen - 2000 – 2002

- Gruppenleiter Vorfeldentwicklung Röntgenröhren bei der

Siemens AG, Medical Solutions, Erlangen - seit 2002

- Abteilungsleitung Vorfeldentwicklung

Röntgen- und Vakuumtechnik bei der Siemens AG,

Medical Solutions, Erlangen

Ehrungen:

- 1995

- Preis für hervorragende wissenschaftliche Leistungen des

Vereins der Freunde der Technischen Universität

Darmstadt e.V. - 2004

- Siemens Medical Innovation Excellence Award 2004

Dr. rer. nat. Karin Söldner

- 06.05.1958

- geboren in Nürnberg

- 1976 – 1982

- Studium der Physik an der Friedrich-Alexander-Universität

Erlangen-Nürnberg - 1982 – 1988

- Doktorand am Physikalischen Institut der Friedrich-

Alexander-Universität Erlangen-Nürnberg - 1987

- Promotion

- 1988 – 1989

- Berechnung von Neutronenflüssen bei der Siemens AG,

Kraftwerk Union (KWU) - 1989 – 1992

- Entwicklung Kugellagertechnologie und Gleitlager-

technologie, Siemens AG, Medical Solutions, RV, Erlangen

- 1992 – 1993

- Mutterschaftsurlaub

- 1993 – 1995

- Mitarbeit im Projekt Gleitlagertechnologie, Betreuung

Fertigungsverlagerung Kugellager zu externer Firma,

Validierungen Kugellagertechnologie

Siemens AG, Medical Solutions, RV, Erlangen - 1995 – 1996

- Projektleitung Projekt Kugellagertechnologie, Qualitäts-

verbesserung und Koordinierung der Aktivitäten in

3 Fertigungslinien Erlangen H, Erlangen TZR und SRW

Siemens AG, Medical Solutions, RV, Erlangen - 1996 – 1999

- Projektleitung bei RV des Förderprojekts der bayerischen

Staatsregierung: Optimierung der Schmierung durch

PVD-Schichten, Kooperation mit GMN, KTmfK der

Universität Erlangen-Nürnberg und MuK der TH Darmstadt,

Entwicklung neuer Lagersysteme für zwei unterschiedliche

CT-Strahler, Siemens AG, Medical Solutions, RV, Erlangen - 1997 – 1998

- Produktverantwortung für CT-Strahler Dura S

Siemens AG, Medical Solutions, RV, Erlangen - 1998 – 1999

- Produktverantwortung für Angiographie-Strahlerfamilie

Megalix

Siemens AG, Medical Solutions, RV, Erlangen - 1999 – 2002

- Mitarbeit im Projekt Diabolo, Koordination von

Konstruktion, Entwicklung, Designverifizierung und

Fertigung bei RVL, Produktverantwortung für Diabolo

Entwicklung Drehkolbenstrahler bis einschließlich

Kundenerprobung

Siemens AG, Medical Solutions, RV, Erlangen - seit 2002

- Projektleiterin und Produktverantwortliche für Straton

Siemens AG, Medical Solutions, RV, Erlangen

Prof. Dr. Dr. rer. nat. Wolfgang Knüpfer

- 10.04.1943

- geboren in Dresden

- 1962 – 1969

- Studium der Physik an der Friedrich-Alexander-Universität

Erlangen-Nürnberg - 1969 – 1972

- Doktorand am Institut für Theoretische Physik,

Friedrich-Alexander-Universität Erlangen-Nürnberg - 1972

- Promotion

- 1972 – 1975

- Assistent am Institut für Theoretische Physik,

Friedrich-Alexander-Universität Erlangen-Nürnberg

Aufbau einer Forschungsgruppe mit Projekten in

Kern- (Kernstruktur) und Strahlenphysik

International anerkannte Zusammenarbeit mit dem Institut

für Kernphysik der TH Darmstadt (S-DALINAC)

- 1975 – 1981

- Forschungsaufenthalte in Washington, Paris, Utrecht

- 1981 – 1983

- Habilitation, Privatdozent

- 1983 – 1985

- Assistent der Entwicklungsleitung Röntgen der

Siemens AG, Medical Solutions, Erlangen - 1985 – 1989

- Entwicklungsleiter X-Ray Speicherleuchtstoffe

und Verstärkerfolien

Siemens AG, Medical Solutions, Erlangen - 1989 – 1992

- Entwicklungsleiter Röntgenbildverstärker

Siemens AG, Medical Solutions, Erlangen - 1992

- Geschäftszweigleiter Bildverstärker

Siemens AG, Medical Solutions, Erlangen - seit 1993

- Geschäftsgebietsleiter Vakuumtechnik

(Entwicklung, Produktion, Marketing/Vertrieb)

für Röntgenröhren und Bildverstärker

Siemens AG, Medical Solutions, Erlangen - 1994

- apl. Professor für Physik an der Friedrich-Alexander-

Universität Erlangen-Nürnberg - seit 1992

- Mitglied der AAPM (American Association of Physicists in

Medicine) - 1997 – 2002

- Mitglied des Wissenschaftlichen Rates der GSI (Gesellschaft

für Schwerionenforschung), Darmstadt

Contact

Spokesperson

Dr. rer. nat. Peter Schardt

Abteilungsleiter Grundlagen / Vorfeldentwicklung

Vacuum Technology (RV)

Siemens AG, Medical Solutions

Günther-Scharowsky-Str. 1

91058 Erlangen

Tel.: +49 (0) 9131 / 73 23 70

Fax: +49 (0) 9131 / 73 24 27

E-Mail: peter.schardt@siemens.com

Press

Axel Wieczorek

Leiter Public Communications

Corporate Communications

Siemens AG, Medical Solutions

Henkestr. 127

91052 Erlangen

Tel.: +49 (0) 9131 / 84 83 35

Fax: +49 (0) 9131 / 84 29 24

E-Mail: a.wieczorek@siemens.com

A description provided by the institutes and companies regarding their nominated projects

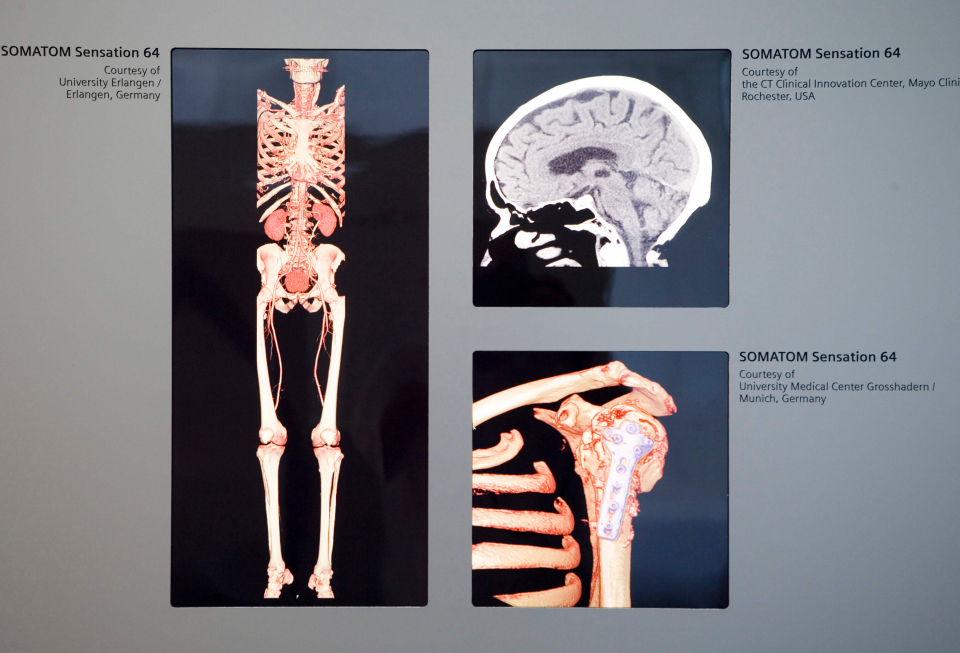

Cardiovascular diseases are the number one cause of death in Germany. In order to detect diseased coronary vessels early, CT scanners are being used every more frequently.

But how do these machines produce the necessary degree of precision?

The innovative X-ray tubes developed by Peter Schardt, Karin Söldner, and Wolfgang Knüpfer form the basis. Peter Schardt heads the X-ray and Vacuum Innovation department at Siemens AG in Erlangen, Karin Söldner is project manager and responsible for Straton, Wolfgang Knüpfer is division manager for vacuum technology for X-ray tubes and image intensifiers.

Rapid rotation for sharp pictures

In computer tomography (CT), cross-sectional pictures of the body are taken using x-rays and joined to produce a 3D image, for example, of the heart. To obtain such detailed pictures of a beating heart, the x-ray source, an x-ray tube, must rotate very rapidly around the patient’s body. In this way, it produces many individual pictures with a very short exposure time. The technology used in conventional CT scanners, however, has come up against limiting factors.

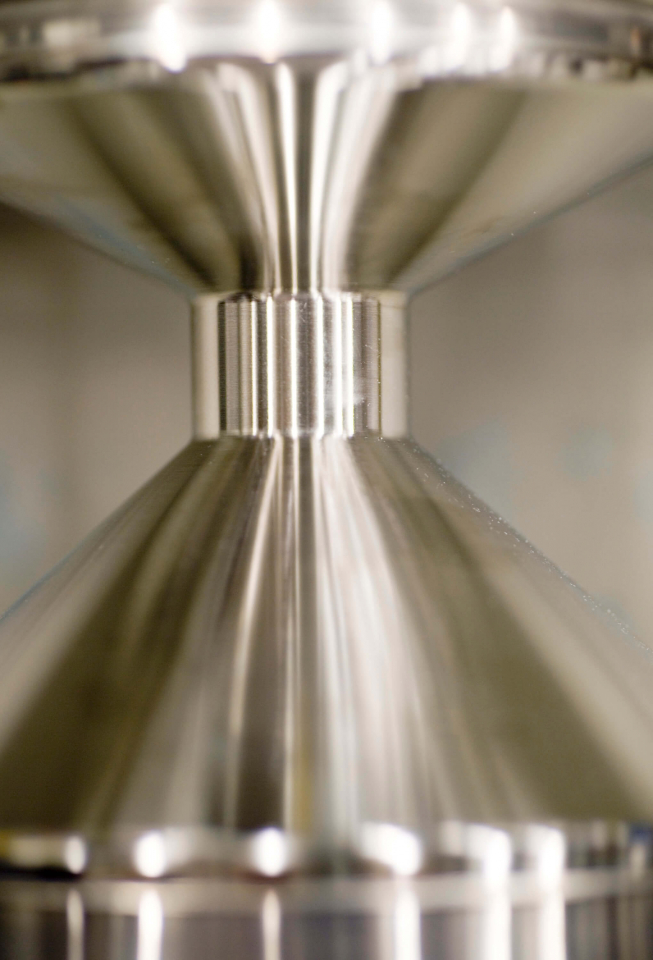

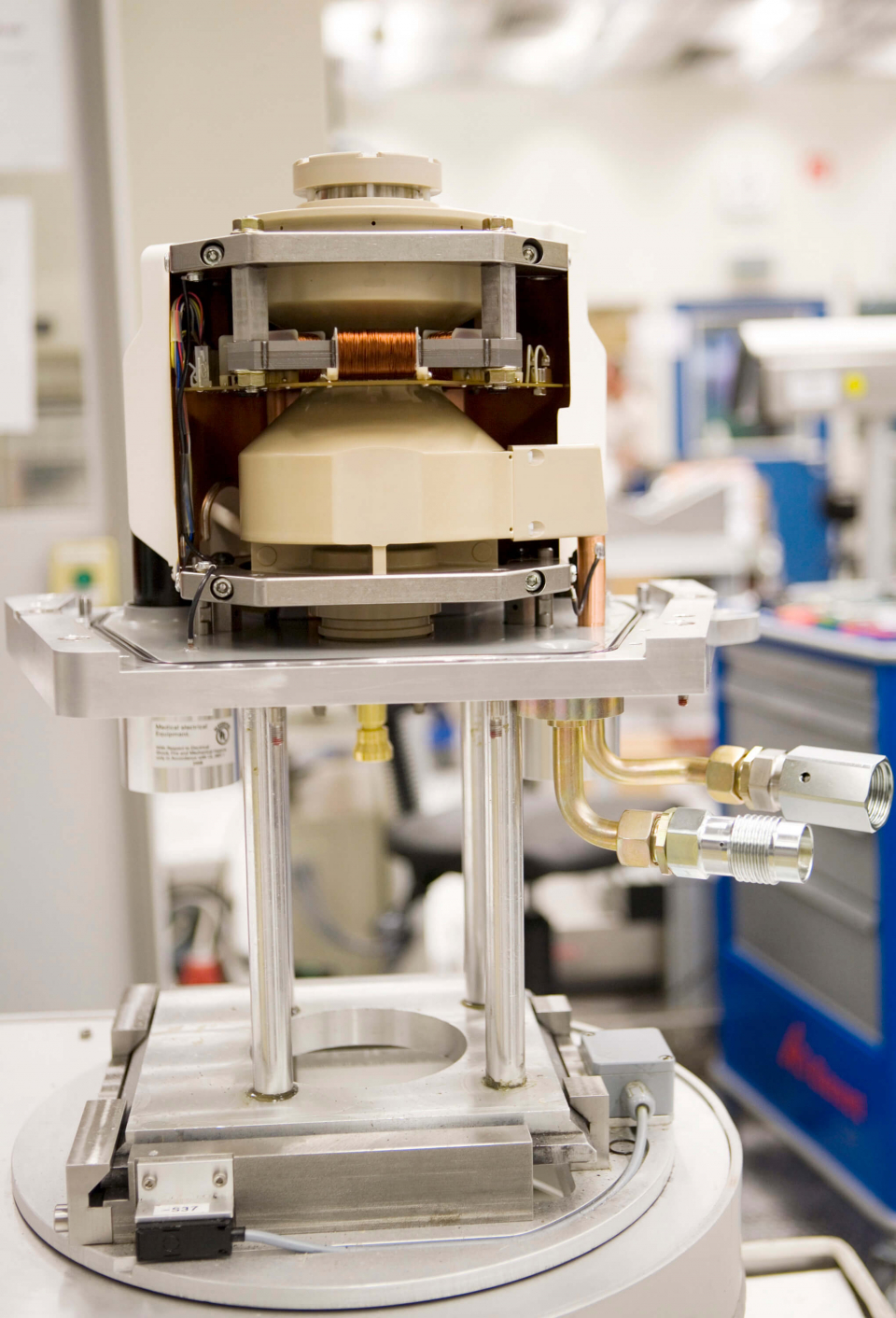

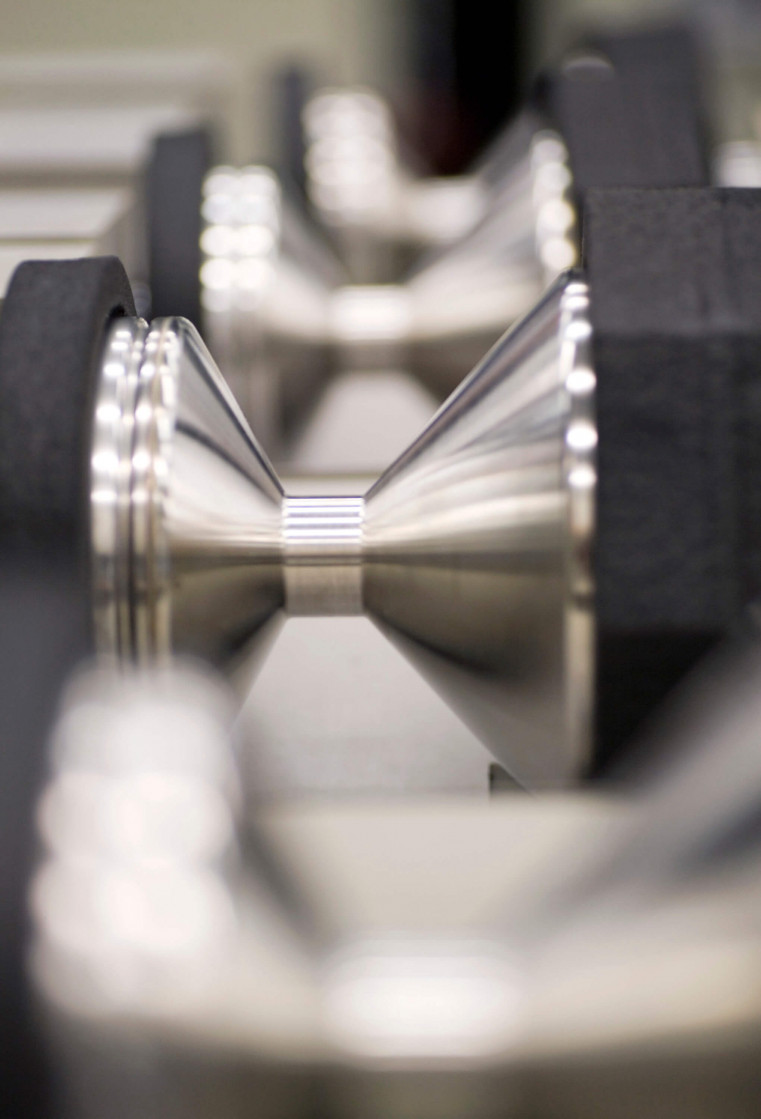

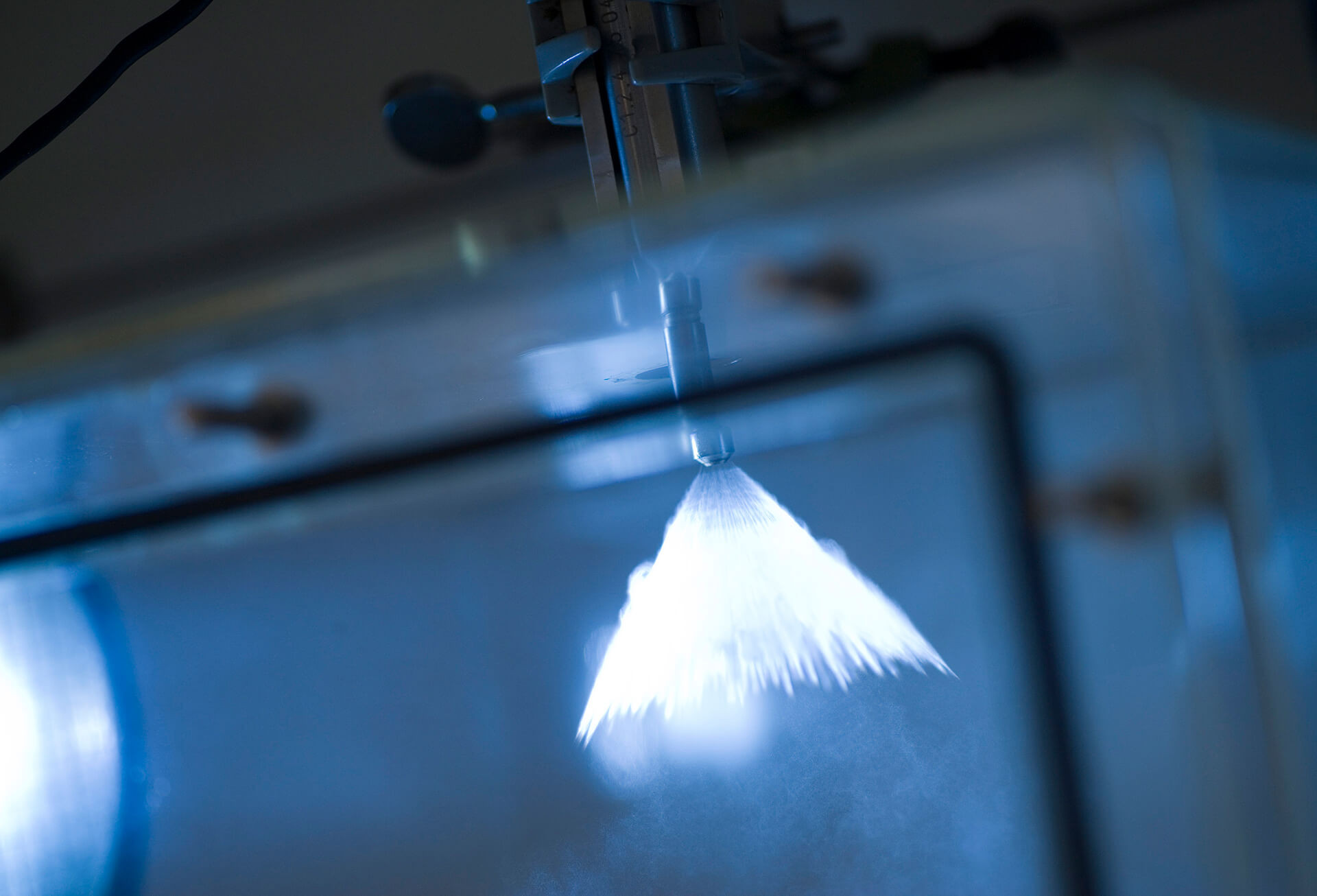

To produce x-rays in the tube anodes, vast amounts of heat are produced. To cool these down fast enough, the x-ray tubes have to be large and heavy. This limits the rate of rotation. The “Straton” x-ray tube technology developed by the three nominees makes it possible to build smaller and yet more powerful x-ray tubes – thanks to the innovative technology in the tubes.

The entire tube turns

Instead of an anode that turns inside the tube but independent of it, the entire x-ray tube rotates rapidly about its axis. The anode is rigidly attached to it and is directly cooled by an oil circuit. The advantage: the x-ray tube design can be built very compact – and cools down very rapidly. The result is a very accurate look inside the human body – with considerably shorter examination times. The coronary arteries and blood vessels can be imaged in brilliant quality with a single CT scan lasting no more than a few seconds. And: patents can be examined despite a rapid or irregular heartbeat – something conventional tomographs can’t do.

With the new, fast x-ray tubes, however, the heartbeat can be virtually frozen on the images. The Straton technology is now used exclusively in the latest generation of Siemens computer tomographs which were introduced in 2003. These scanners have also improved emergency diagnostics: the physician can produce a whole body scan in around 20 seconds in order to obtain a picture of an accident victim’s internal injuries.

The right to nominate outstanding achievements for the German Future Award is incumbent on leading German institutions in Science and Industry as well as foundations.

The Project „Revolutionary high-speed, high-resolution X-ray tube for computer tomography“ was nominated by the Verband Technisch-Wissenschaftlicher Vereine.

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache