Winner 2005

Piezo-Injektoren

The key to success is in a highly precise injection of fuel. This is an area in which Friedrich Boecking, Klaus Egger, and Hans Meixner have set new standards. The three nominated researchers work at suppliers to the automotive industry – although at two directly competing companies: Friedrich Boecking heads the development division Common Rail Injectors Car at the Stuttgart firm Robert Bosch GmbH, Klaus Egger is a member of the board at Siemens VDO Automotive AG in Regensburg, and Hans Meixner is an authorized agent of the department for sensor and actuator technology (ZT) at Siemens Research in Munich.

Pressure and dosage are decisive

Approximately one in two vehicles registered in Germany in 2004 runs on diesel fuel. Diesel vehicles owe their popularity above all to direct fuel injection. It makes engines efficient and quiet – and provides economical fuel consumption.

more details

Resumes

Dipl.-Ing. Friedrich Boecking

- 08.06.1961

- geboren in Trier

- 1989 – 1995

- Studium des Maschinenbaus an der Technischen

Hochschule Karlsruhe - 1989 – 1995

- Entwickler von Düsen und DHK bei der

Robert Bosch GmbH, Stuttgart - 1995 – 1998

- Leitung Forschungsprojekt Einspritzverlaufsformung von

Dieseleinspritzinjektoren mittels Piezo-Aktoren bei der

Robert Bosch GmbH, Stuttgart

- 1998 – 2003

- Abteilungsleitung Entwicklung Piezo-Injektoren

bei der Robert Bosch GmbH, Stuttgart - seit 2003

- Entwicklungsbereichsleiter Common-Rail-Injektoren Pkw,

Entwicklungsverantwortung für Common-Rail-Injektoraktivitäten

Pkw bei der Robert Bosch GmbH, Stuttgart

Dr.-Ing. Klaus Egger

- 22.06.1951

- geboren in Graz / Österreich

- 1969 – 1975

- Studium des Maschinenbaus an der Technischen

Universität Graz - 1976

- Institut für Verbrennungskraftmaschinen, Technische

Universität Graz - 1976

- Promotion

- 1975 – 1978

- Assistent an der Technischen Universität Graz

- 1978 – 1980

- Ingenieur in der M1-Motorenentwicklung bei der

AVL LIST GmbH, Graz

- 1980 – 1982

- Gruppenleiter Einspritzung, Vorentwicklung bei der

BMW Motoren GmbH, Steyr - 1982 – 1983

- Abteilungsleiter Einspritzung, Vorentwicklung bei der

BMW Motoren GmbH, Steyr - 1983 – 1984

- Entwicklungsleiter bei der Voest-Alpine Friedmann GmbH,

Linz - 1984 – 1990

- Geschäftsführer bei der Voest-Alpine Automotive GmbH,

Linz und Wien - 1990 – 1994

- Geschäftsführer des Bereichs Dieseleinspritzausrüstung

bei der Robert Bosch AG, Wien - 1994 – 1995

- Leiter Systembereich Common Rail bei der Robert Bosch

GmbH, Stuttgart - 1996

- Leiter des Bereichs Automobiltechnik, Referat Zentrale

Technik, Strategische Planung bei der Siemens AG,

Regensburg - 1996 – 1998

- Leiter Geschäftszweig Dieselsysteme bei der

Siemens AG, Regensburg - 1998 – 2001

- Leiter Geschäftsgebiet Antriebsstrang bei der

Siemens AG, Regensburg - seit 2001

- Vorstandsmitglied der Siemens VDO Automotive AG, Regensburg

Prof. Dr. rer. nat. Hans Meixner

- 06.10.1939

- geboren in Marl / NRW

- 1961 – 1970

- Studium der Chemie, Mathematik und Physik an der

Universität Hamburg und der Technischen Universität

München - 1970

- Doktorand am Physik Department der Technischen

Universität München - 1970 – 1972

- Tutor am Mathematischen Institut der Ludwig-Maximilians-

Universität München - 1972

- Promotion

- 1972 – 1973

- Wissenschaftlicher Assistent am Physik Department der

Technischen Universität München - 1973 – 1980

- Angestellter in der Zentralen Forschung und Entwicklung

bei der Siemens AG, München - 1980 – 1985

- Laborleiter für Anwendungstechniken, Bereich ZT,

Forschung bei der Siemens AG, München - 1985 – 1991

- Gruppenbevollmächtigter Bereich ZT, Forschung

bei der Siemens AG, München - 1991 – 1992

- Unterschriftsberechtigung i.V. Bereich ZT, Forschung

bei der Siemens AG, München - 1992

- Leiter der Kerntechnologie: Sensorik, Mess-, Steuer- und

Regelungstechnik Bereich ZT, Forschung bei der Siemens

AG, München - seit 1992

- Abteilungsbevollmächtigter für Sensor- und Aktuatortechnik

Bereich ZT, Forschung bei der Siemens AG, München

Weitere Tätigkeiten:

- Industrial Advisory Board Member of Berkeley Sensor and Actuator Center,University of California

Editorial Board Member of Institute of Physics Publishing, UK

Kurator der Fraunhofer-Gesellschaft

Beirat des Forschungszentrums Karlsruhe

Beirat Linz Center of Mechatronics GmbH

Beirat EnOcean

Beirat First Sensor

Mitglied der Programm- und Steering Committees:

European Material Research Society

Eurosensors

Chemical Sensors

Sensortagung Bad Nauheim/Ludwigsburg des Arbeitsausschusses

„Chemische Grundlagen und Anwendungen der Sensortechnik“

in der Dechema

Vorsitzender des Arbeitsausschusses „ADAPTRONIC“ des VDI

(Physikalische Technologien)

Vorstand bei Anakon

Contact

Spokesperson

Dipl.-Ing. Friedrich Boecking

Entwicklungsbereichsleiter Common-Rail-Injektoren Pkw

Robert Bosch GmbH

Wernerstr. 51

70469 Stuttgart

Tel.: +49 (0) 711 / 81 14 51 52

E-Mail: friedrich.boecking@bosch.de

Press

Thomas Knoll

Media and Public Relations Kraftfahrzeugtechnik

Robert Bosch GmbH

Wernerstr. 51

70469 Stuttgart

Tel.: +49 (0) 711 / 81 17 088

Fax: +49 (0) 711 / 81 17 656

E-Mail: thomas.knoll@bosch.com

Johannes Winterhagen

Corporate Communications

Siemens VDO Automotive AG

Sodener Str. 9

65824 Schwalbach

Tel.: +49 (0) 6196 / 87 23 48

Fax: +49 (0) 6196 / 87 41 94

E-Mail: johannes.winterhagen@siemens.com

A description provided by the institutes and companies regarding their nominated projects

Vehicles with diesel engines are becoming ever more popular. They are low on fuel consumption and much cleaner than cars with spontaneous ignition from earlier years of manufacture.

What is behind this incredible progress in diesel engines?

The key to success is in a highly precise injection of fuel. This is an area in which Friedrich Boecking, Klaus Egger, and Hans Meixner have set new standards. The three nominated researchers work at suppliers to the automotive industry – although at two directly competing companies: Friedrich Boecking heads the development division Common Rail Injectors Car at the Stuttgart firm Robert Bosch GmbH, Klaus Egger is a member of the board at Siemens VDO Automotive AG in Regensburg, and Hans Meixner is an authorized agent of the department for sensor and actuator technology (ZT) at Siemens Research in Munich.

Pressure and dosage are decisive

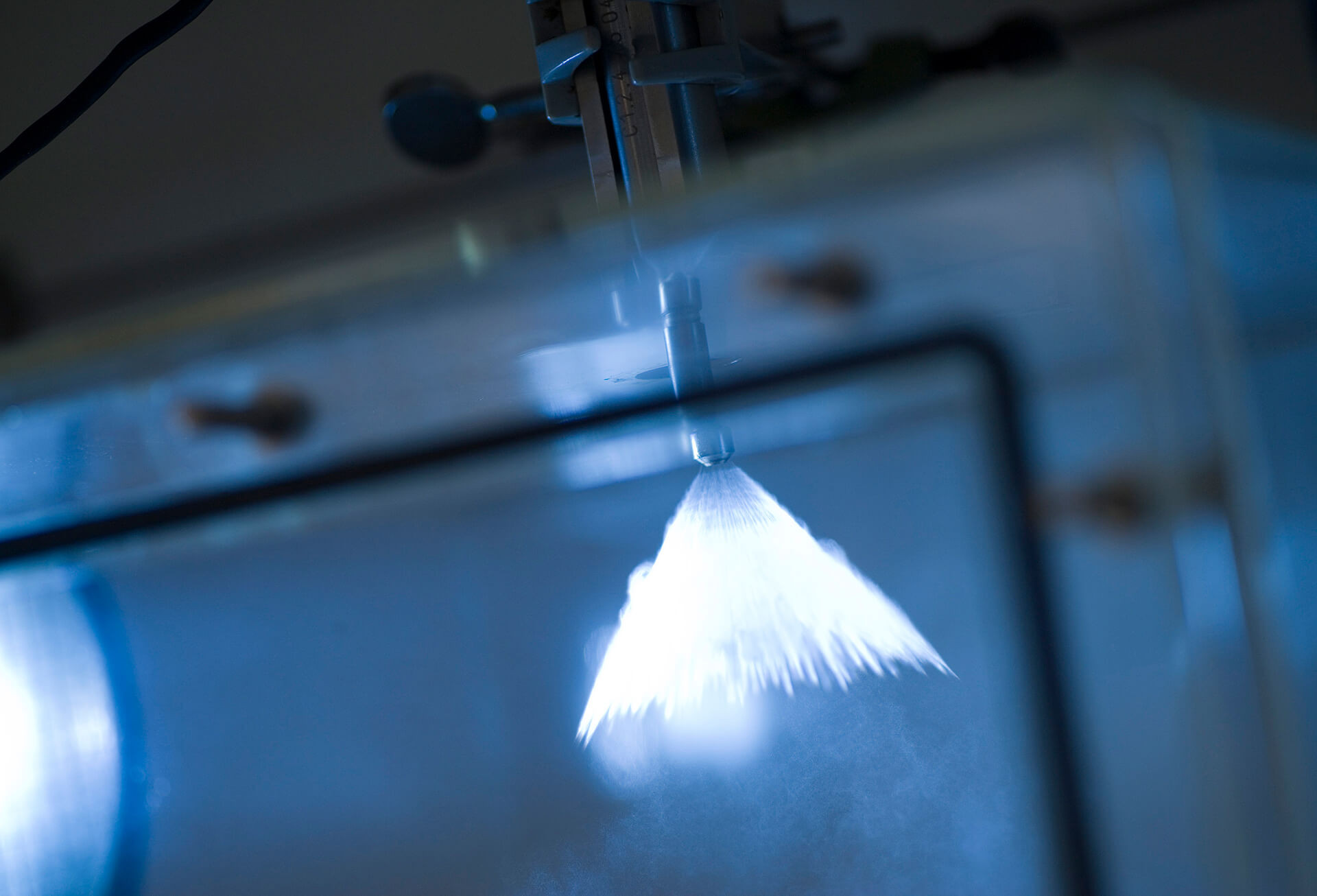

Approximately one in two vehicles registered in Germany in 2004 runs on diesel fuel. Diesel vehicles owe their popularity above all to direct fuel injection. It makes engines efficient and quiet – and provides economical fuel consumption. In direct injection systems, a pump pressurizes the fuel and injects it through an injection valve into the cylinder’s combustion chamber. The higher the pressure and more precise the injection time and quantity, the more efficient combustion is.

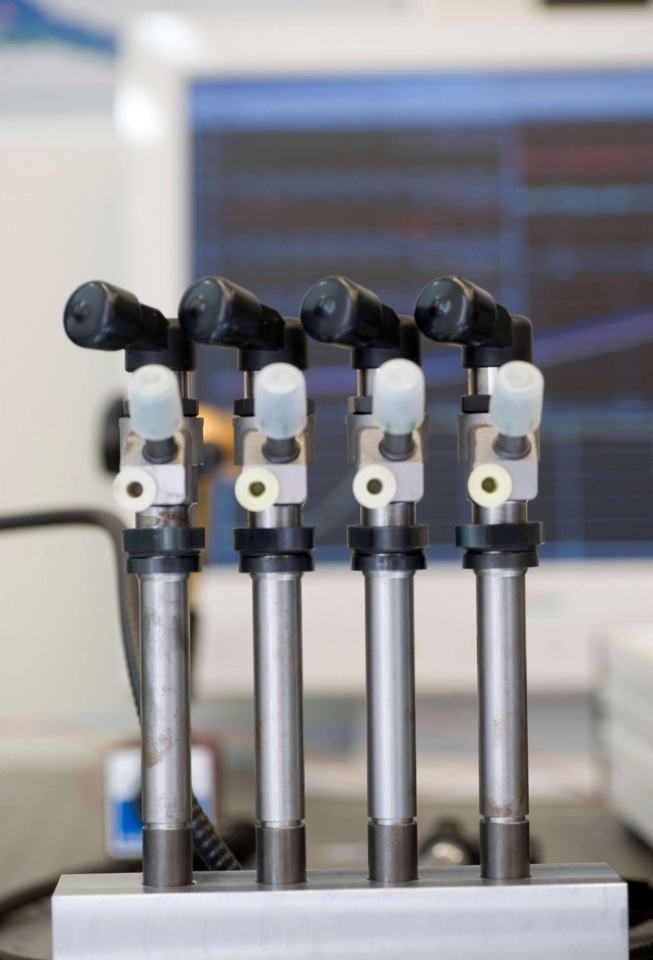

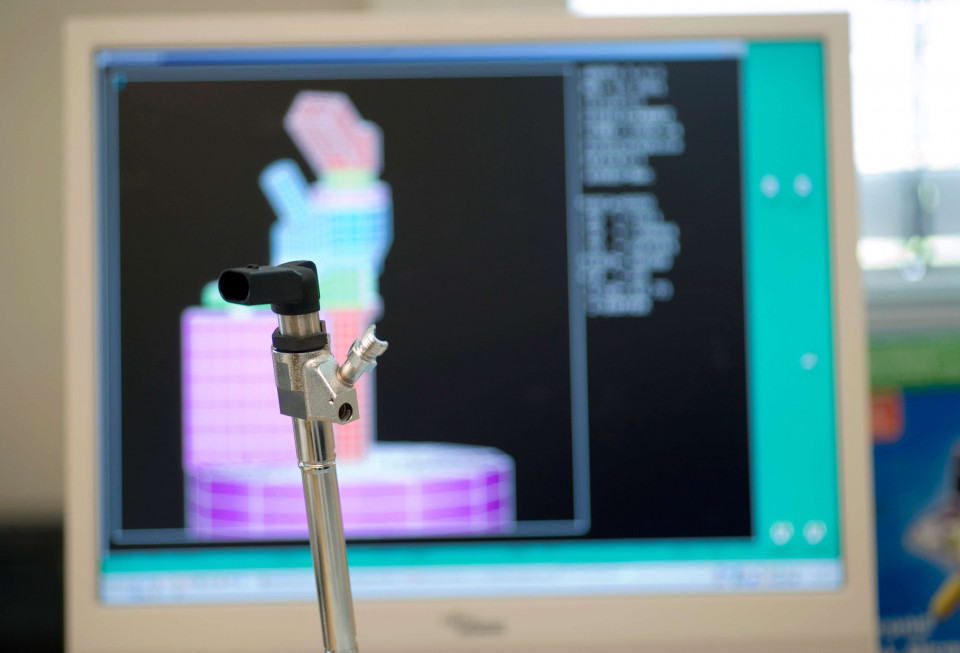

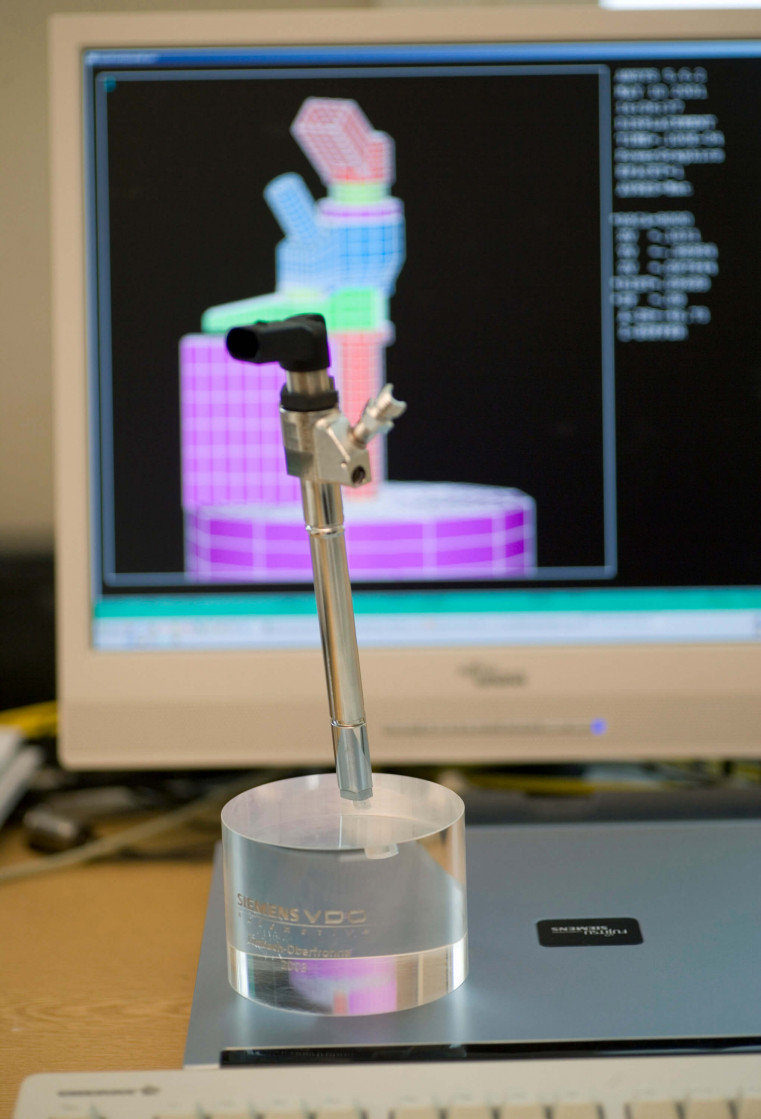

The piezo injectors developed independently by research and development teams both at Bosch and Siemens VDO are especially precise. In these valves, regulators open and shut the fuel injectors making use of the piezo electric effect that occurs in certain crystalline materials: If an current is applied to them, the material yields instantaneously. This produces forces which can be exploited to control fuel injection.

High speed provides precision

The advantage of piezo technology: it opens and closes the injection value up to five times as fast as conventional solenoid valves. This improves metering accuracy, thereby producing fewer pollutants during fuel combustion and reducing nitrous oxide emissions by up to 20 percent. The same is true for the particulate matter found in diesel exhaust. Fuel consumption drops, and the engine runs quiet.

Boecking, Eggert, and Meixner had great market success with the development of the piezo electric injectors. The first injectors went into production in 2000. By the end of 2006, Bosch and Siemens VDO had together manufactured around 25 million units. For manufacture of the injectors alone, the two companies employ around 14,000 people worldwide, 6,400 of them in Germany.

The right to nominate outstanding achievements for the German Future Award is incumbent on leading German institutions in Science and Industry as well as foundations.

The Project „Piezo injectors: A new technologyfor clean diesel and gasoline engines“ was nominated by the Stiftung Werner-von-Siemens-Ring .

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache