Nominee 2025

Biomass instead of microplastics

To understand why this is far from trivial, we need to look back to the very beginnings of life on our planet. From the moment life emerged, nature has relied on a perfect recycling system. It builds complex molecules from carbon atoms, links many of these molecules together to form organic polymers, and from these creates the structures of plants and animals. When they die, microorganisms break these structures back down. The carbon they contain is released into the atmosphere as carbon dioxide, taken up again by plants, and rebuilt into organic molecules and polymers — and the cycle begins anew.

Why this system has been working for billions of years is no secret: nature only builds molecules from carbon that it can break down again with the help of microorganisms. It's perfect recycling.

More Details

Resume

Dr.-Ing. Anne Lamp

13.03.1990

Born in Hamburg, Germany

2009 – 2012

B.Sc. in Process Engineering, Hamburg University of Technology, Germany

2010 – 2014

Beiersdorf AG: Working Student R&D

2012 – 2015

M.Sc. in Process Engineering, Hamburg University of Technology

2015 – 2020

PhD in Process Engineering, Hamburg University of Technology, German

Institute of Environmental Technology and Energy Economics, TU Hamburg: Research Scientist & Team Leader2015 – 2020

VERBIO Vereinigte BioEnergie AG, Project Engineer R&D

2020 – 2021

VERBIO Vereinigte BioEnergie AG, Part-Time Leader R&D

Since 2020

traceless materials GmbH, CEO & Co-founder

Patents

8 patents

Publications

Isci, A., Erdem, G.M., Elmaci, S.B., Sakiyan, O., Lamp, A., Kaltschmitt, M. Effect of microwave-assisted deep eutectic solvent pretreatment on lignocellulose structure and bioconversion of wheat straw. Cellulose (accepted 2020).

Lamp, A., Kaltschmitt, M., Lüdtke, O. Protein recovery from bioethanol stillage by liquid hot water treatment. Journal of Supercritical Fluids, 155 (2020), 104624.

Lamp, A. Protein recovery from bioethanol stillage in the context of integrated biorefineries. ProcessNet Jahrestagung 2018, Aachen, Germany, 12-13 September 2018. Published in Chemie Ingenieur Technik, 90 (2018), 9, 2018.

Lamp, A., Kaltschmitt, M., Lüdtke, O. Improved HPLC-method for estimation and correction of amino acid losses during hydrolysis of unknown samples. Analytical Biochemistry, 543 (2018), 140-145.

Dieckmann, C., Lamp, A., Schmidt, L.M., Andersen, L., Baetge, S., Kaltschmitt, M. Von der Biogasanlage zur Bioraffinerie – Perspektiven für zukünftige Biogasanlagenkonzepte. Zeitschrift für Energiewirtschaft, 42 (2018), 3, 235-256.

Andersen, L., Lamp, A., Dieckmann, C., Baetge, S., Schmidt, L.M., Kaltschmitt, M. Biogas plants as key units of biorefinery concepts: Options and their assessment. Journal of Biotechnology, 283 (2018), 130-139.

Schmidt, L.M., Andersen, L., Dieckmann, C., Lamp, A., Kaltschmitt, M. The Biorefinery Approach. In: Meyers R. (Hrsg.) Encyclopedia of Sustainability Science and Technology. Springer, New York, NY, 2018.

Further activities

2020

Planet A Ventures GmbH: Advisor for the development of an automated impact analysis tool for startups

2020

Cirplus GmbH: Advisor for material circularity, recyclate quality and certifications

2014 – 2020

Cradle To Cradle NGO: Founder and group leader regional group Hamburg

Honors and Awards

2022 + 2023

Capital "Top 40 under 40"

Company Awards

KPMG Award 2025

CHEManager Innovation Pitch of the Year 2024

Deutscher Nachhaltigkeitspreis / Next Economy Award: Winner 2022, Nominee again in 2025

Deutscher Gründerpreis 2022, Winner Startup Category

Wissenschaftspreis 2022 Best Startup

Sina Spingler

18.10.1990

Born in Hamburg, Germany

2010 – 2014

B.Sc. in Industrial Engineering (integrated degree program), Nordakademie Business School, Elmshorn, Germany

Mankiewicz Gebr. & Co. GmbH & Co. KG, Trainee, integrated degree student, Hamburg, Germany2012 – 2012

Semester Abroad, UCES, Universidad de Ciencias Empresariales y Sociales, Buenos Aires, Argentina

2014 – 2016

Mankiewicz Gebr. & Co. GmbH & Co. KG, Project Engineer, Hamburg

2016 – 2017

Mankiewicz Gebr. & Co. GmbH & Co. KG, Project Manager, Charleston, SC, USA

2017 – 2019

M.BA (full-time), ESADE Business School, Ramon Llull University, Barcelona, Spain

2018 – 2018

MBA MACH Intern: Industry Solution Expert – Government, Berlin, Germany

2019 – 2022

Microsoft Deutschland GmbH, Customer Success Manager, Business Applications, Hamburg

2022 – 2023

Microsoft Deutschland GmbH, Customer Success Lead Business Applications, Hamburg

2023 – 2025

traceless materials GmbH, Head of Operations

Since 2025

traceless materials GmbH, Managing Director, COO

Honors and Awards

Esade Women in Leadership Scholarship

Company Awards (traceless materials GmbH)

KPMG Award 2025

Deutscher Nachhaltigkeitspreis, Kategorie Produkt (German Sustainability Award), Nominee 2025

CHEManager Innovation Pitch of the Year 2024

Innovation Award "Renewable Material of the Year 2023", 3rd prize

Deutscher Nachhaltigkeitspreis / Next Economy Award: Winner 2022

Deutscher Gründerpreis 2022, Winner Startup Category

Hamburger Gründerpreis 2022, Winner Startup Category

German Startup Awards, Female Newcomer of the Year 2022

Wissenschaftspreis 2022 Best Startup

1. Platz in Germany's Top 50 Start-Up Ranking 2021

Falling Walls Venture, Science Breakthrough Of The Year 2021

Darboven IDEE Förderpreis, 1st prize 2021

Green Alley Award, Winner 2021

Impact Festival Award for Hardware Solutions, Winner 2021

Hello Tomorrow Global Challenge, Finalist 2021

Biopolymer Innovation Award, 2nd 2021

Future Hamburg Award, 2nd 2021

C-Voucher Award, 2nd 2021

Advanced Materials Competition, Winner 2020

Niklas Rambow

18.10.1990

Born in Stade, Germany

2009 – 2013

Bachelor of Engineering “Composites”, Private University of Applied Sciences, Stade, Germany

2103 – 2019

Premium AEROTEC GmbH, Project Engineer “Site Planning”, Nordenham, Germany

2019 – 2021

Premium AEROTEC GmbH, Agile Team “Hangar 100”, Nordenham

Since 2021

traceless materials GmbH, Head of Technology Development, Hamburg, Germany

Further Activities

2019-2020

IBIS Interkulturelle Arbeitsstelle e.V. – Voluntary work as a certified integration assistant for refugees

Honors and Awards

2018

Dean’s List of Academic Excellence, University of Sydney

Company Awards

KPMG Award 2025

Deutscher Nachhaltigkeitspreis, Kategorie Produkt (German Sustainability Award), Nominee 2025

CHEManager Innovation Pitch of the Year 2024

Innovation Award "Renewable Material of the Year 2023", 3rd prize

Deutscher Nachhaltigkeitspreis / Next Economy Award: Winner 2022

Deutscher Gründerpreis 2022, Winner Startup Category

Hamburger Gründerpreis 2022, Winner Startup Category

German Startup Awards, Female Newcomer of the Year 2022

Wissenschaftspreis 2022 Best Startup

1. Platz in Germany's Top 50 Start-Up Ranking 2021

Falling Walls Venture, Science Breakthrough Of The Year 2021

Darboven IDEE Förderpreis, 1st prize 2021

Green Alley Award, Winner 2021

Impact Festival Award for Hardware Solutions, Winner 2021

Hello Tomorrow Global Challenge, Finalist 2021

Biopolymer Innovation Award, 2nd 2021

Future Hamburg Award, 2nd 2021

C-Voucher Award, 2nd 2021

Advanced Materials Competition, Winner 2020

Contact

Coordination and Press

Ivonne Sokoll

Head of Marketing

traceless materials GmbH

Großmoorbogen 7a

21079 Hamburg

Mobile: +49 (0) 151 / 55 42 71 84

E-Mail: ivonne.sokoll@traceless.eu

Web: www.traceless.eu

Spokesperson

Dr.-Ing. Anne Lamp

Geschäftsführerin

traceless materials GmbH

Großmoorbogen 7a

21079 Hamburg

Mobile: +49 176 (0) / 44 25 77 17

E-Mail: anne.lamp@traceless.eu

Web: www.traceless.eu

A description provided by the institutes and companies regarding their nominated projects

Biomass instead of microplastics – innovative biomaterials replace fossil plastics

Tracing global plastic pollution is the mission of traceless materials®. The innovative biomaterial traceless® and its production process are the result of co-founder and CEO Anne Lamp's doctoral thesis at the Technical University of Hamburg and are a showcase product for a climate-friendly and circular bioeconomy.

The traceless® material is obtained from plant residues from the agricultural industry in a resource-saving process and can replace fossil-based plastics in products that are difficult to recycle or easily end up in the environment. With this innovation, traceless® is a global pioneer of innovative natural polymers, going far beyond familiar material categories such as plastics or bioplastics:

In contrast, traceless® is fossil- and plastic-free, based on rapidly renewable biomass residues, and is compostable in a short time. The natural polymers in granulate form are already being produced in the company's own plant. On the road to industrialization, the first large-scale production plant will open in Hamburg in fall 2025. This material innovation thus offers the potential to contribute to solving the global plastic waste problem and to establishing a climate-neutral, recyclable industry. As a cleantech technology, it helps to secure global competitiveness, future-proof industrial jobs, and reduce dependence on fossil raw materials.

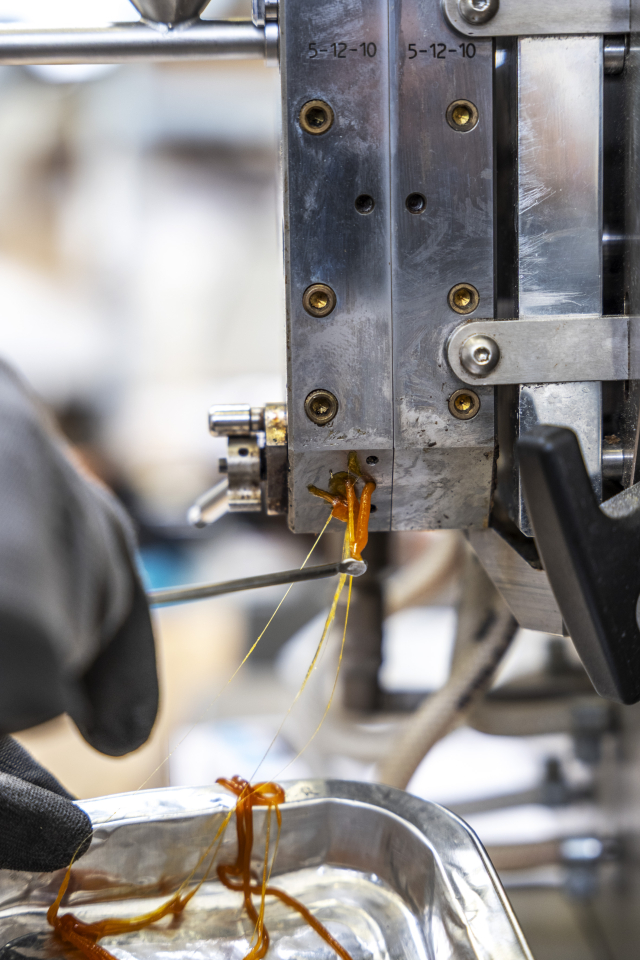

State of the art and new material category: natural polymers traceless® is shaping a new generation of natural polymer materials. It is based on the use of natural polymers—long-chain molecules that have similar properties to plastics but are naturally occurring and not synthetically or artificially produced. Examples of so-called natural polymers include cellulose, lignin, alginates, natural fats, and proteins. The traceless material is produced using a resource-conserving, energy-efficient production process ( ) that extracts these natural polymers.

Although natural polymers were at the beginning of the history of plastics, they fell into oblivion with the advent of fossil raw materials and the chemical industry and have been little researched and hardly used commercially in recent decades. In view of the aggravating plastic pollution, innovations relating to natural polymers are now emerging again worldwide. traceless® is a pioneer and leader both in the EU and globally, and will be the first company to implement a comparable extraction process on an industrial scale.

Existing collaborations

traceless is cooperating with renowned European brand providers and manufacturers to develop product applications. The team has been working with e-commerce retailer OTTO on the development of plastic-free shipping bags since 2020. A first pilot product in the packaging sector has been successfully tested on the market with fashion retailer C&A since 2022. In 2024, French fry forks made from traceless® material were used for the first time at a series of large outdoor concerts in cooperation with international catering provider Aramark. In the same year, a collaboration with the Mondi Group, a leading international paper and packaging manufacturer, was announced. Mondi uses the traceless® material as an alternative to conventional paper coatings, where plastics improve the sealing and barrier properties of the paper. At the same time, recyclability for existing paper recycling cycles is ensured.

Regulatory classification

As a pioneer of innovative natural polymer materials, traceless also offers regulatory advantages. Since the material is based on natural polymers that are neither chemically modified nor synthetically polymerized, traceless is not a plastic in the regulatory sense, but a natural substance. It is therefore not subject to laws aimed at reducing single-use plastics, such as the EU Single-Use Plastics Directive. This makes it currently the only thermoplastic material alternative for products such as cutlery or drinking straws that can no longer be made from single-use plastic or for which high taxes apply in the case of plastic. For customers, traceless is therefore a regulatory-compliant, easy-to-integrate, and sustainable choice in all product areas where a complete switch to reusable products is not yet feasible.

Future prospects

traceless® makes a substantial contribution to solving global plastic pollution, the resource crisis, climate change, and biodiversity loss. As biomaterial pioneers, they are driving the green transformation of the materials sector. This benefits not only the planet, but also the economy and society: Scaling the innovation to an industrial level will help secure German and European competitiveness and make Germany a technology leader in the bio-based industry. This is in line with the goals of strategically reducing fossil fuel dependencies, establishing a net-zero circular economy, and attracting sustainable cleantech industries to the region in the long term.

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache