Winner 2025

Powerhouse for the climate

Dipl.-Ing. Christoffer Uhr, Dipl.-Ing. Kai Weeber, and Dipl.-Ing. Pierre Andrieu are certain: Yes, there is another way, because they have already taken it. Consistent, focused, and successful. They have developed a fuel cell system, their Fuel Cell Power Module, which generates electricity from hydrogen and enables heavy trucks to be operated electrically and emission-free, without any restrictions on range or payload for transported goods.

To understand how the team has turned this technology into a real long-distance game changer, it helps to understand how a fuel cell works. A fuel cell can generate electricity by consuming a fuel. However, this does not involve combustion, but rather an electrochemical reaction.

More Details

Resume

Dipl.-Ing. Christoffer Uhr

24.12.1969

Born in Jugenheim (Bergstraße district), Germany

1990 – 1995

Studies of general mechanical engineering at the Karlsruhe Institute of Technology (KIT)

1995 – 2001

Development Engineer for Inline Pumps and Common Rail Pumps, Robert Bosch GmbH, Stuttgart, Germany

2001 – 2006

Group Leader Development Common Rail Injectors, Robert Bosch GmbH, Stuttgart

2006 – 2011

Head of Development Rail and Injector, Robert Bosch AG, Linz, Austria

2011 – 2012

Product Manager, Common Rail Injectors, Robert Bosch GmbH, Stuttgart

2012 – 2020

Head of Development for Common Rail Injector, Robert Bosch GmbH, Stuttgart

2020 – today

Head of Development for Fuel Cell and Electrolysis, Robert Bosch GmbH, Stuttgart

Patents

2000 – today

5 patent applications, of which 2 are active as of July 10, 2025

Publications

2018

“Renewable Paraffinic Fuels – Pioneer for e-Fuels?!”, 2nd International Conference FEV Zero CO2 Mobility in Aachen

2018

“Common rail injectors for passenger car and commercial vehicle diesel engines“, Diesel Engines Manual

2022

“The launch of the first Bosch fuel cell system”, 43rd International Vienna Motor Symposium

2022

“Bosch’s Heavy Duty Fuel Cell System - The Powerpack for Long Haul Trucks”, 31st Aachen Colloquium Sustainable Mobility

Other Activities

2025

Lecture "Power Solutions for CO2-Neutral Energy Sources", FKFS Research Institute, Stuttgart

2024/2025

Lectures at high schools in Bruchsal on the topic of "The Hydrogen Economy"

Dipl.-Ing. (FH) Kai Weeber

19.02.1970

Born in Leonberg (Böblingen district), Germany

1987 – 1991

Information Technology Training, Siemens AG

1991 – 1993

Community service

1993 – 1997

Studies of Electrical Engineering with a focus on Control Engineering at Heilbronn University, Germany

1997 – 2000

Engineer for Vehicle Dynamics Control Systems, Robert Bosch GmbH, Schwieberdingen, Germany

2001 – 2007

Project Manager Driver Assistance Systems, Robert Bosch GmbH, Leonberg, Germany

2007 – 2011

Group Leader System Development Occupant Protection Systems, Robert Bosch GmbH, Schwieberdingen

2011 – 2014

Head of Research Group, Hydrogen Technologies, Robert Bosch GmbH, Schwieberdingen

2015 – today

Program Director, Chemical Energy Converters, Research and Advanced Engineering, Robert Bosch GmbH, Renningen, Germany/Wuxi, China/Sunnyvale, USA

Patents

2000 – today

57 patent applications, of which 22 are active as of July 10, 2025

Publications (selection)

2018

“Changes in Power Generation And Distribution And The Role of SOFC“, EFCF, Luzern

2020

“Solid Oxide Fuel Cell In a Changing Energy Landscape“, TU München

2021

“The Importance of Mobile Fuel Cells in the Context of the Energy Transition,” Future Mobility Congress, Stuttgart

2022

“Market Launch of the First Fuel Cell System from Bosch”, 43rd International Vienna Motor Symposium

2023

“Hydrogen Economy: Electrolysis & Fuel Cells for Stationary and Road Based Applications”, VDI Forum, Ulm

Other activities

Member of the Hydrogen Advisory Board of the State of Baden-Württemberg

Member of the Board of Trustees of the Center for Solar Energy and Hydrogen Research Baden-Württemberg

Auditor of national research institutions

Dipl.-Ing. Pierre Andrieu

17.01.1978

Born in Sainte Catherine-Les-Arras, France

1998 – 2001

Studies in General Mechanical Engineering / Production Engineering at the École d'ingénieur ENSIAME – Valenciennes university, France

Master’s degree in Business Administration and Management, Valenciennes university2001 – 2006

Development Engineer unit injector, Robert Bosch GmbH, Rommelsbach, Germany

2011

Certification “Project Management Professional“ (PMP), Project Management Institute (PMI)

2006 – 2012

Project leader development Common Rail Injector, Robert Bosch GmbH, Stuttgart, Germany

2013 – 2018

Platform Project leader development Common Rail Injector, Robert Bosch GmbH, Stuttgart

2018 – 2021

Group leader development Common Rail Injector for European customer projects, Robert Bosch GmbH, Stuttgart

2021 – today

Project- / Department director for platform / customer projects Fuel Cell, Robert Bosch GmbH, Stuttgart

Patents

2010

WO2010000507A1 – Solenoid valve, fuel injector, and method for the production thereof

Honors and Awards

2022

Bosch Innovation Award for Fuel Cell Power Modul (FCPM)

Contact

Coordination and Press

Jörn Ebberg

Robert Bosch GmbH

External Communications

Postfach 10 60 50

70049 Stuttgart

Mobile: +49 (0) 172 / 57 31 347

E-Mail: Joern.Ebberg@de.bosch.com

Web: www.bosch.com

Sprecher

Christoffer Uhr

Robert Bosch GmbH

Power Solutions

Postfach 30 02 20

70442 Stuttgart

Mobile: +49 (0) 172 / 81 89 628

E-Mail: Christoffer.Uhr1@de.bosch.com

Web: www.bosch.com

A description provided by the institutes and companies regarding their nominated projects

Powerhouse for the climate – electric long-haul trucks powered by hydrogen

Climate change is the greatest global challenge of our time. Greenhouse gases such as carbon dioxide (CO2) are causing global warming. Alongside industry and buildings, road traffic is one of the main sources of CO2. At the same time, the transportation of goods and freight by road is the backbone of the global economy and continues to grow. A team of Bosch engineers comprising Christoffer Uhr, Kai Weeber, and Pierre Andrieu has developed a solution for powering trucks with hydrogen that generates no CO2 and can be used worldwide: the fuel-cell power module (FCPM).

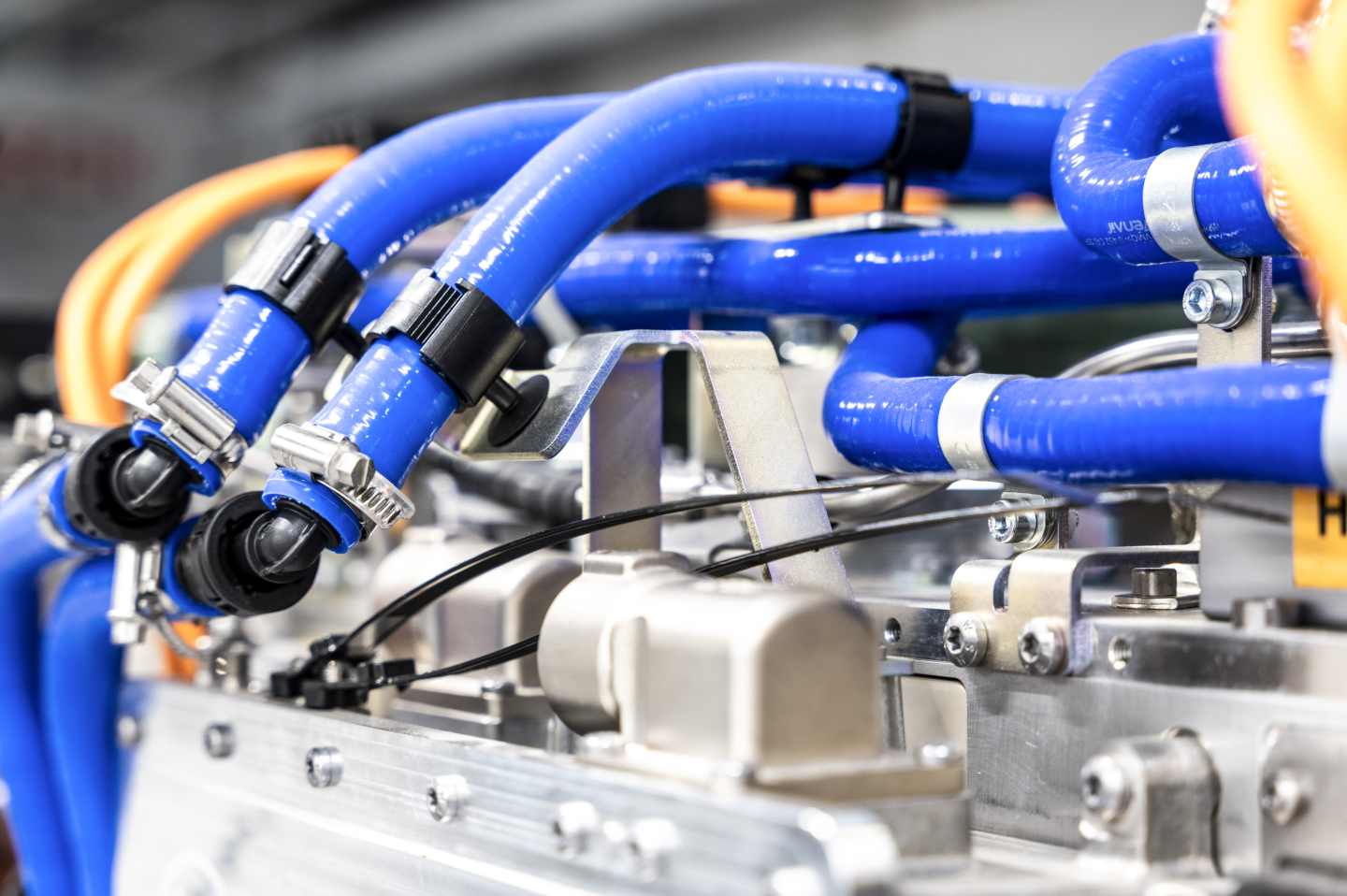

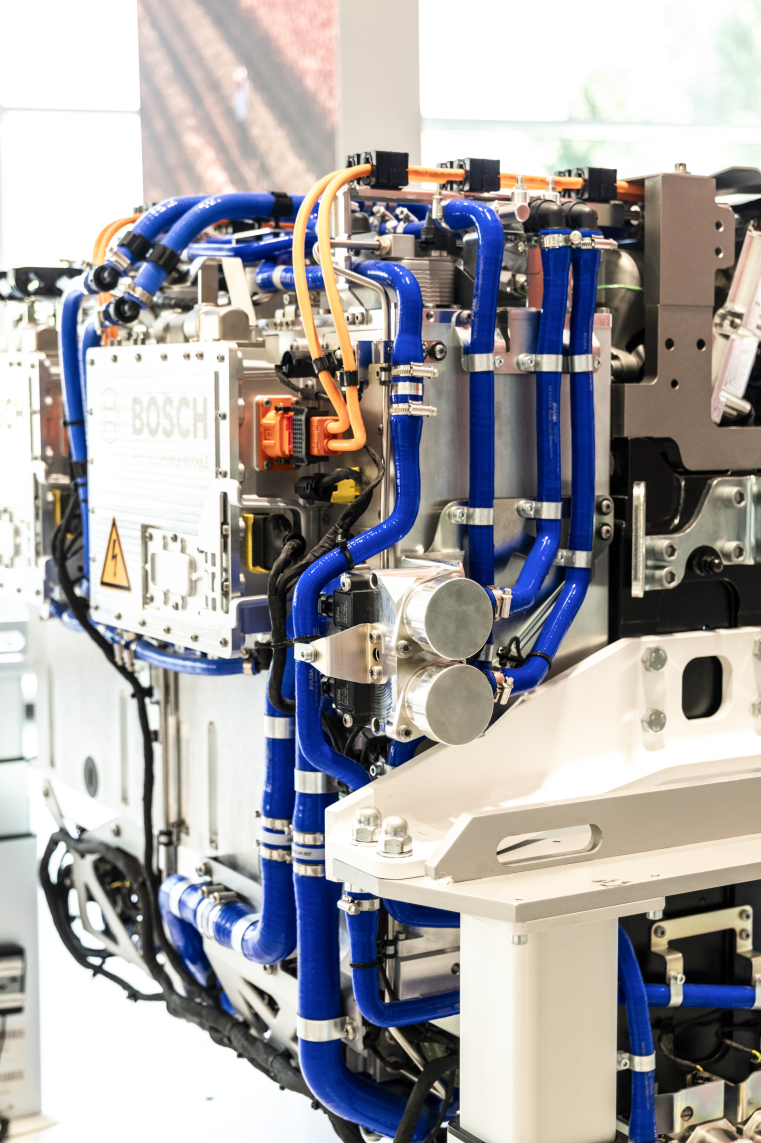

The FCPM converts hydrogen and oxygen into electricity using proton exchange membrane (PEM) technology. This makes it easy to power a 40-ton truck with electricity. Apart from waste heat, all that remains is pure water – no pollutants, no CO2. The module is designed to fit into the space that in over 95 percent of all trucks was previously occupied by the combustion engine. This is an advantage for truck makers since they can build on existing vehicle platforms.

Freight forwarders and logistics companies also benefit, because the FCPM allows them to use the hydrogen trucks just as they would diesel-powered ones: the system offers high levels of robustness and durability for the vehicle’s entire service life, as well as short times for hydrogen refueling of around 20 minutes and long ranges of up to 1,000 kilometers. Added to this is virtually whisper-quiet operation without vibration and the certainty of being able to comply with all current and future climate regulations.

The fuel cells are the heart of the power module. At first glance, they are not very spectacular. They are only roughly the size of a standard envelope, and weigh less than 100 grams. To make them capable of propelling a heavy truck, several hundred fuel cells are combined. This combination, known as a stack, provides a total electrical output of more than 100 kilowatts. Depending on the requirements, two stacks can be installed in a fuel-cell power module, resulting in a system output of over 200 kilowatts.

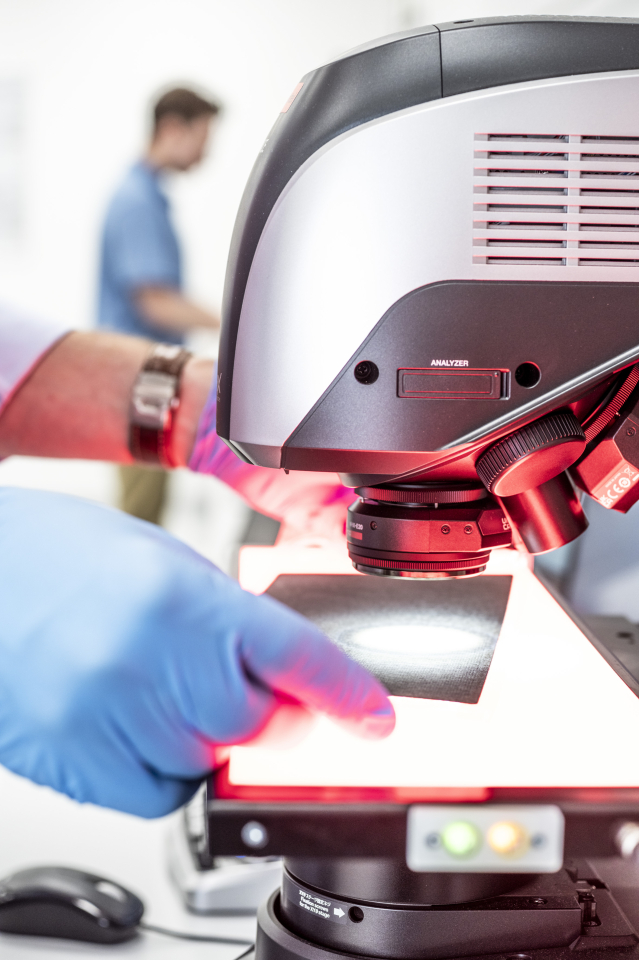

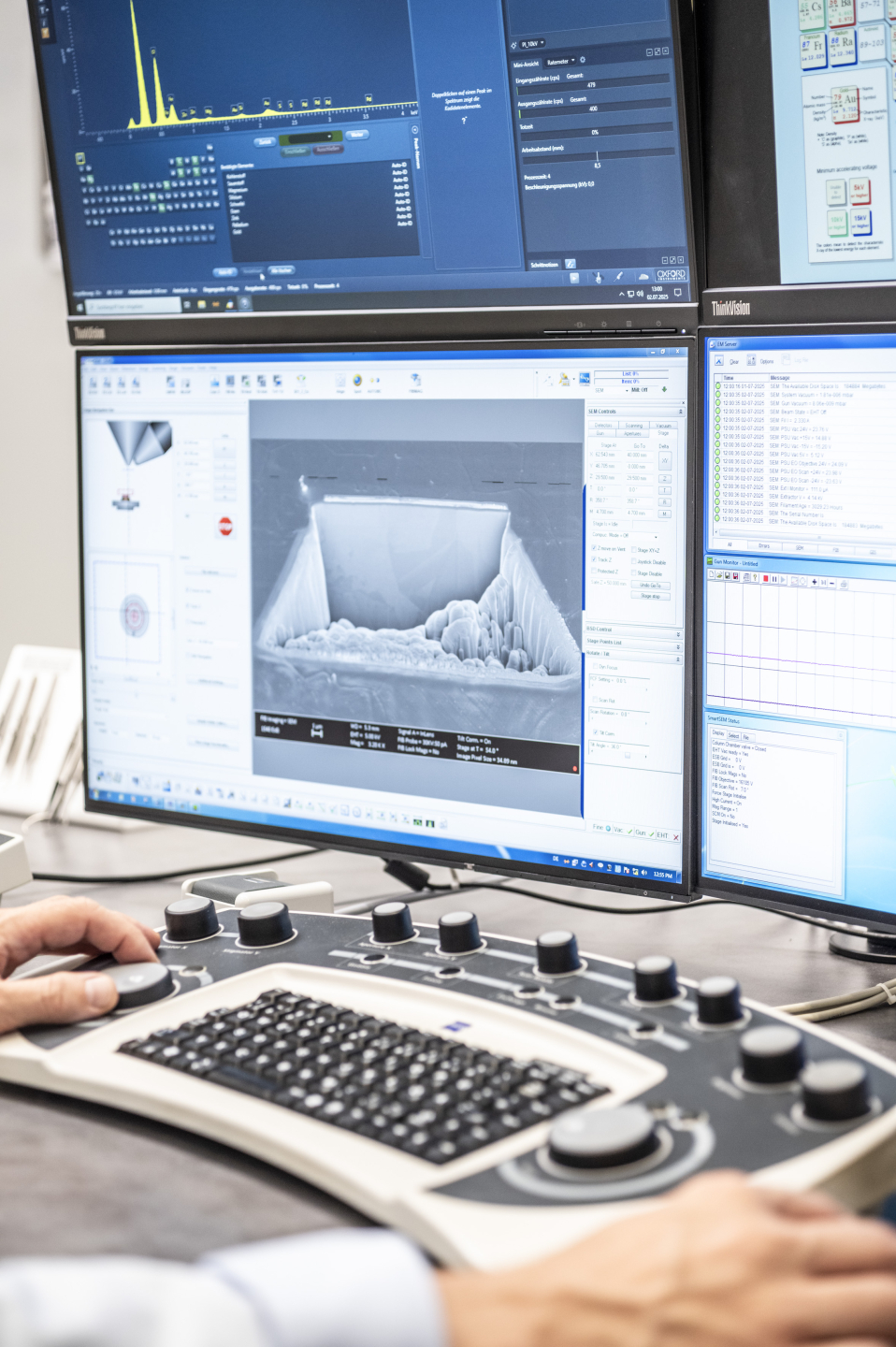

For the FCPM, Bosch drew on knowledge gathered over decades of research and development work in powertrain components. The pre-development project for the current drive module started back in 2014. Bosch is leveraging its collective manufacturing expertise as well: in the long run, more than half the value added is to be created in-house, and Bosch’s special-purpose machinery unit will provide more than 50 percent of the manufacturing equipment needed. Knowledge is also being shared in areas such as assembly, testing, coating, and laser welding technology. Consisting of more than a thousand individual parts and weighing around 500 kilograms, the FCPM is the most complex system Bosch has ever developed in its almost 140-year history. Volume production launched in Stuttgart-Feuerbach in mid-2023 and a little later in Chongqing, China. When manufacturing mobile fuel-cell systems, one of the technologies used is high-speed laser welding. This process originated in injector production and makes the 1.2 kilometers of weld seams in each stack hydrogen-tight – something only Bosch can do.

Apart from the stack, the system contains many other components, including a hydrogen metering valve, a hydrogen recirculation pump, and an electric air compressor. Together, they ensure that the fuel cells are supplied with hydrogen and oxygen, so that the molecules can react there to generate electricity. That electricity powers the vehicle’s motor directly and is also stored in a backup battery. Unlike in purely battery-electric heavy trucks, the battery in a fuel-cell truck weighs much less. Overall, a heavy truck with a fuel-cell powertrain is around 4 metric tons lighter than a comparable commercial vehicle with today’s battery technology – this is good news for the truck’s available payload. Another point that shouldn’t go overlooked is that, unlike batteries, hardly any critical raw materials are used in constructing the FCPM.

The FCPM is already on the road in several thousand trucks worldwide. In Europe and North America in particular, the further ramp-up depends on the political course set for the rapid expansion of a hydrogen economy. Meanwhile, the systems in operation are feeding in data for further development. The FCPM actually has a double existence: one in reality and one as a digital twin in virtual space. Bosch uses this to collect specific information on things like temperature, pressure profile, and wear, drawing key findings that have already been incorporated into the development of the second generation.

The FCPM isn’t just an automotive component; it’s also a building block of the urgently needed hydrogen economy. As long as trade is conducted worldwide and goods and freight are transported across national borders and continents, there will be a need for a chemical energy source. From Bosch’s point of view, hydrogen is the ideal choice. It can be produced anywhere in a climate-neutral way, it can store surplus renewable energy, and it can be transported by pipeline, ship, or truck.

In addition, the FCPM can power ships or, say, provide data centers with renewable electricity. Bosch also uses the PEM technology developed for the FCPM for other solutions. One of these involves reversing the principle of the fuel cell: instead of generating electricity from water and oxygen, the company also offers technology for electrolyzers that produce hydrogen from water and renewable electricity – climate friendly, without any CO2.

About Bosch

The Bosch Group is a leading global supplier of technology and services. It employs roughly 418,000 associates worldwide (as of December 31, 2024). The company generated sales of 90.3 billion euros in 2024. Its operations are divided into four business sectors: Mobility, Industrial Technology, Consumer Goods, and Energy and Building Technology. With its business activities, the company aims to use technology to help shape universal trends such as automation, electrification, digitalization, connectivity, and an orientation to sustainability. In this context, Bosch’s broad diversification across regions and industries strengthens its innovativeness and robustness. Bosch uses its proven expertise in sensor technology, software, and services to offer customers cross-domain solutions from a single source. It also applies its expertise in connectivity and artificial intelligence in order to develop and manufacture user-friendly, sustainable products. With technology that is “Invented for life,” Bosch wants to help improve quality of life and conserve natural resources. The Bosch Group comprises Robert Bosch GmbH and its roughly 490 subsidiary and regional companies in over 60 countries. Including sales and service partners, Bosch’s global manufacturing, engineering, and sales network covers nearly every country in the world. Bosch’s innovative strength is key to the company’s further development. At 136 locations across the globe, Bosch employs some 87,000 associates in research and development.

The company was set up in Stuttgart in 1886 by Robert Bosch (1861–1942) as “Workshop for Precision Mechanics and Electrical Engineering.” The special ownership structure of Robert Bosch GmbH guarantees the entrepreneurial freedom of the Bosch Group, making it possible for the company to plan over the long term and to undertake significant upfront investments in the safeguarding of its future. Ninety-four percent of the share capital of Robert Bosch GmbH is held by Robert Bosch Stiftung GmbH, a limited liability company with a charitable purpose. The remaining shares are held by Robert Bosch GmbH and by a company owned by the Bosch family. The majority of voting rights are held by Robert Bosch Industrietreuhand KG. It is entrusted with the task of safeguarding the company’s long-term existence and in particular its financial independence – in line with the mission handed down in the will of the company’s founder, Robert Bosch.

Additional information is available online at www.bosch.com, www.bosch-press.com.

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache