Nominee 2023

Counteract climate change

Antje Bulmann, Viktor Fetter and Tobias Horn have developed a useful module for this purpose. The nominated team refined a technology originally stemming from aerospace applications that extracts carbon dioxide (CO2) from the air. It can be used to actively filter carbon dioxide gas from the atmosphere, thereby compensating for unavoidable emissions in industry, transport, energy generation, and agriculture, for example.

What’s more, the innovation cleans up CO2 and simultaneously makes it possible to use the gas for other applications. It basically kills two birds with one stone – and paves the way to a manufacturing practice that no longer drives climate change. Antje Bulman heads the development project at Airbus in Hamburg, Viktor Fetter is the tech lead and project manager, and Tobias Horn is chief engineer for the Direct Air Capture technology for terrestrial applications.

The Intergovernmental Panel on Climate Change (IPCC) emphasized the need for negative CO2 emissions in its most recent report. The international scientists involved consider the removal from the atmosphere of the greenhouse gas CO2 in particular to be an important element to be able to reach the set climate target: limit global warming to a maximum of 1.5 to 2 degrees Celsius compared to the temperature level before the beginning of industrialization. The nominees have laid the foundation for achieving this goal.

Airbus originally developed the underlying technology as a system to filter CO2 from the air for the International Space Station (ISS) – as part of the life-support system for astronauts on board. The module reduces the CO2 content of air in the space station, providing a more efficient oxygen supply for the crew. The nominees used the module as the basis for a system to remove carbon dioxide from the air efficiently even in terrestrial applications. The advantage of the space technology is that it can handle the lower CO2 concentrations on the Earth's surface. Despite its major impact on the climate, CO2 makes up only about 0.04 percent of the ambient atmosphere. This is a major challenge for the new filter technology.

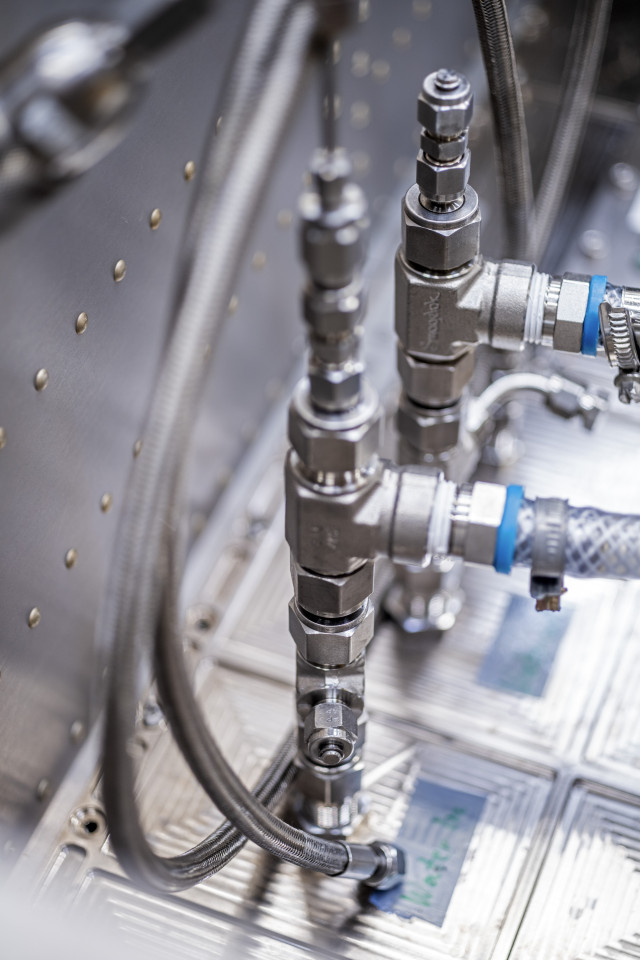

Filtering carbon dioxide from the air takes place gradually in the so-called direct air capture module. First, a fan draws in air which then flows over a filter made of a solid amine-based material – a chemical compound containing nitrogen. The Airbus team engineered an amine ideally suited to capture CO2 and has patented it under the brand name Astrine. When the filter material is saturated with CO2 removed from the air, a second process step follows: the adsorber beds are heated – and release the carbon dioxide. The gas is captured in a concentrated form and can then be used, processed or permanently stored in different ways.

More Details

Resume

Dipl.-Kauffrau Antje Bulmann

- 28.07.1980

- born in Schwerin

- 1999

- High school diploma with qualification examination for university entrance (Abitur), Gymnasium am Sonnenberg, Crivitz

- 2006

- Career start at WestLB, Düsseldorf in Communications and in the Investor Relations division

- Seit 2009

- Bereich Kommunikation und Investor Relations

- 2010

- Airbus SAS Toulouse und später Airbus Operations GmbH Hamburg Gründerin und Geschäftsführerin der Kugu UG

- Since 2017

- Airbus SAS Toulouse and later Airbus Operations GmbH Hamburg

- 2020 – 2026

- Majors in Law, International Management. University degree/Diploma, Universität Rostock, University of Applied Sciences, Bremen and Universidad Abierta Interamericana, Buenos Aires/Argentina

Further Activities

- 2017

- Founding member of AGO Alliance for rare diseases of the AGO genes

- 2022

- Alumni of Airminers Incubation Programs

- 2023

- Advisory Board Carbon Unbound

- 2023

- Alumni of EIT Climate KIC Initiative “remove”

Publications

- 2007

- Publication: Added value with greater value – Sustainable corporate success by investing in corporate social responsibility

Awards

- 2011

- Hamburger Gründerpreis, the Founder’s Award given by the city of Hamburg; 2nd place

Viktor Fetter, B.Eng.

- 23.11.1983

- Born in Krasnodar

- 2000 – 2003

- Apprenticeship in Mechatronics / Graduation according Chamber of Industry and Commerce; Carl-Zeiss Oberkochen

- 2004

- Employee as Mechatronics, Intecma GmbH Aalen; deployment includes Daimler Chrysler, VW, Steiff, Festo, Kiener Maschinenbau

- 2005 - 2009

- Study of mechatronics, focus on automation technology, University of Applied Sciences in Aalen.

Bachelor Thesis: ‘Development and optimization of an automated system for a reliable nutrient supply of cartilage samples’ - 2008

- Research Assistant, University of Applied Sciences Aalen

- 2009

- Development Engineer , EADS Astrium GmbH Space Transportation Immenstaad, Development, optimization and calibration of the Life- Support-System of MIS (Mice In Space)

- 2009 - 2014

- System Engineer in the Bio- and Life-Science Department, E-Nose – Electronic Nose for the identification of contamination caused by fungi and bacteria on the ISS, I-DEC - Biological Identification and Decontamination

- 2021

- System Architect for the Post-ISS ESA Module SciHab (Habitation)

Business Developer for the terrestrial application of CO2 Capture technology (Decarbonising Buildings, Horticulture, Hyperloop) - 2022 - 2023

- Project Manager for IDA – Internal Dosimetry Array; First Payload for the Lunar Gateway Station to measure the radiation in space

- Since 2022

- Tech Lead for SinC – Direct Air Capture Technology for terrestrial applications; Airbus Defence and Space GmbH Immenstaad

Further Activities

- 2017

- Analog Astronaut / Board Engineer in the Sirius 17 Isolation Study

German representative in a simulation of the conditions of a long-term space mission to study the biomedical and psychological problems in humans associated with isolation in confined spaces

Patents

- CCapture device and method for removing CO2 from air, and production system (pending)

Electrically heated, functionally coated mesh for CO2 capture (pending)

Method for decontamination of bacterial loads via bacteriophages

Method and device for decontamination of a habitat

Mounting device (ring sealing with suction disc principle)

Publications

- Various lectures at congresses as speaker and co-author in the areas of "Circular Carbon Economy", “Biological Life Support Systems” and "Life Science”

Dipl.-Ing. Tobias Horn

- 05.01.1981

- born in Worms

- 2000

- Abitur at Gauß-Gymnasium, Worms

- 2000 – 2001

- Basic military service

- 2001 – 2008

- Studies of Mechanical Engineering at the Technical University of Darmstadt, Major field of study: Thermo- & Aerodynamics, Degree: Diploma

- 2008 - 2013

- Research assistant at the Institute for Technical Thermodynamics, Technical University of Darmstadt, Topic: Marangoni convection on structured surfaces in reduced and earth gravity

- 2013 - 2022

- Lead System Engineer in the field of „Science & Life Support Missions”, Airbus Defense & Space, Immenstaad

- Since 2022

- Chief Engineer for SinC – Direct Air Capture Technology for terrestrial applications

Further Activities

- 2001 - 2005

- Management board member at Jugendclub Altrhein e.V.

- 2006 - 2013

- Participation in multiple ESA / DLR Parabolic Flight Campaigns as student assistant and project manager

- 2006 - 2008

- Diploma thesis at the Department of Mechanical Engineering, University of Alberta, Canada, Topic: „Phenomenological investigation of the influence of super-hydrophobic surfaces on icing“

Patents

- 2 pending patents in the field of „Direct-Air-Capture“

Publications

- 2 national and international publications and lectures

Contact

Coordination and Press

Heiko Stolzke

Externe Kommunikation – Airbus Commercial Aircraft

Airbus Operations GmbH

Kreetslag 10

21129 Hamburg

Phone: +49 (0) 40 / 74 37 30 16

E-Mail: heiko.stolzke@airbus.com

www.airbus.com

Spokesperson

Antje Bulmann

Venture Lead - Direct Air Capture

Airbus Operations GmbH

Kreetslag 10

21129 Hamburg

Phone: +49 (0) 172 / 28 62 949

A description provided by the institutes and companies regarding their nominated projects

Counteract climate change – Removing CO2 from the atmosphere and making it useful

Climate protection in aviation can be achieved through various means. In addition to fleet modernization, sustainable aviation fuels (SAF), more efficient flight operations, and future technologies like hydrogen propulsion, the removal of CO2 from the atmosphere also plays a key role. To this end, the Airbus team has further developed a space application in a technology transfer, enabling efficient removal of CO2 from the atmosphere.

The Technology

The underlying technology was originally developed as a life support system for the International Space Station (ISS). The so-called Advanced Closed Loop System (ACLS) extracts carbon dioxide from the air in the space station, providing a more efficient oxygen supply for the astronauts. We use the Carbon Capture module of the ACLS as the basis for our Direct Air Capture module, as it can efficiently filter CO2 from the air in environments with low CO2 concentration. This capture process can be divided into two steps: First, a fan draws in air, which flows over a solid, amine-based filter that selectively binds the CO2 in the so-called adsorber beds. Airbus has patented the solid amine Astrine™ required for this process, which efficiently captures CO2 even at low concentrations. This first phase continues until the amine resin becomes saturated with CO2. In the second step, the adsorber beds are regenerated by applying heat, releasing the CO2 as concentrated gas that can be further processed.

The Benefits

CO2 filtered from the air can be useful in various ways. On one hand, it makes an important contribution to climate protection in conjunction with other technologies. On the other hand, CO2 can also serve as a raw material for products that require carbon. This opens up possibilities to close the CO2 cycle and extract previously emitted CO2 from the atmosphere. Where CO2 is currently used in combustion processes with significant emissions, Direct Air Capture will provide CO2 directly from the air on-site. This also presents a commercial aspect: The market demand for permanently filtered CO2 from the air will be substantial, estimated at 50-150 Mt/CO2 per year in 2030, with a market value of 10-30 billion US dollars.

Applications of Direct Air Capture

The first Direct Air Capture plant was commissioned in December 2022 and tested in a closed greenhouse. The device filters CO2 from the air and directs it into the greenhouse to accelerate plant photosynthesis, leading to faster plant growth and better space efficiency.

Another application is the production of sustainable fuels based on so-called synthesis gas. This process relies on the use of CO2 and sustainably produced hydrogen, resulting in artificially generated fuel at the end of the so-called PtL process.

CO2 can also serve as a raw material for chemically manufactured materials that are currently produced from crude oil. An example of this is carbon fibers, which require carbon for their production. If this carbon comes from Direct Air Capture, the CO2 footprint of the material is significantly improved, possibly even creating carbon-negative materials. According to the Intergovernmental Panel on Climate Change (IPCC), only eliminating emissions will not be enough to achieve net-zero emissions worldwide by 2050 – long-term removal of CO2 from the atmosphere will also be necessary.

The technology transfer and further development from space exploration can make a significant contribution to decarbonizing aviation and beyond through Direct Air Capture.

About Airbus

Airbus is the leading aircraft manufacturer that offers the most advanced and comprehensive family of commercial aircraft available on the market, driven by the vision of "We are pioneers of sustainable aerospace for a safe and united world". Airbus aircraft cover the entire capacity range from 100 to well over 400 seats. As a pioneer in innovative and sustainable technologies, Airbus provides some of the most fuel-efficient and quietest aircraft in the world. To date, Airbus has sold more than 22,700 aircraft to over 380 customers worldwide, with over 14,700 already delivered (as of June 2022). The order backlog amounts to nearly 8,000 aircraft to be delivered in the coming years. Airbus employs approximately 135,000 employees from over 100 different countries across the entire group. As a globally operating company, Airbus has design and manufacturing facilities in France, Germany, the United Kingdom, and Spain, as well as subsidiaries in the USA, China, Japan, India, and the Middle East. Additionally, Airbus operates spare parts and training centers in Europe, the USA, and Asia and provides around-the-clock customer support services to maximize the profitability of its fleets.

The right to nominate outstanding achievements for the Deutscher Zukunftspreis is incumbent on leading German institutions in science and industry as well as foundations. The project "Counteract climate change – Removing CO2 from the atmosphere and making it useful” was submitted by BDI - Bundesverband der Deutschen Industrie e.V..

Federal President Frank Walter Steinmeier will present the Deutscher Zukunftspreis to one of the three nominated teams on November 22, 2023.

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache