Nominee 2015

3-D-Druck

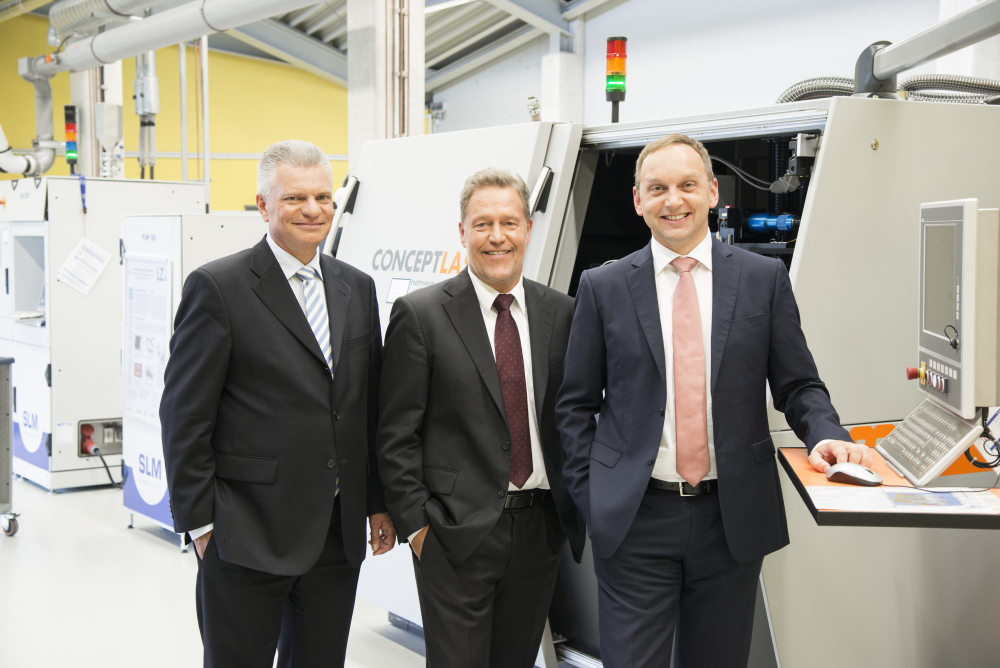

Dipl.-Ing. (FH) Peter Sander, Prof. Dr.-Ing. Claus Emmelmann and Dipl.-Ing. Frank Herzog have developed a process that is now ready to be employed to print three-dimensional metal parts. These parts are slated to be used for the first time in the Airbus A350. Peter Sander is head of the Emerging Technologies & Concepts division at Airbus, Claus Emmelmann is CEO of LZN Laser Zentrum Nord as well as head of the Institute of Laser and System Technologies (iLAS) at the Hamburg University of Technology (TUHH), Frank Herzog is Managing Director of Concept Laser in Lichtenfels.

3-D printing has been making headlines for several years. Unlike conventional methods of production, products are not stamped, sawn or cut out of a material block, rather a part is built layer by layer. This has numerous advantages: it uses less material and energy, which in turn protects resources and the climate. Designers also have greater freedom in part design. And, prototypes, single pieces, or small series of products can be manufactured with relative ease and inexpensively. However, to date only certain materials have been able to be used for additive manufacturing (AM), such as plastics or easy-to-melt alloys.

more details

Resumes

Dipl.-Ing. (FH) Peter Sander

- 18.05.1957

- Born in Munich

- 1981

- Mechanical Engineer Degree in Production Technology at University Bremen

- 1981

- Entry in today’s Airbus Operations GmbH, Hamburg

- 1981 - 1982

- Assistant Production Manager

- 1983 - 1994

- Specialist functions including management in the field of Industrial Engineering

- 1994 - 2000

- Manager in the field of Tools, Design and Manufacturing

- 2000 - 2006

- Manager of CFRP large parts production in Stade

- 2006 - 2007

- Head of Parts Production in Bremen

- 2007 - 2009

- Head of A380 Operations in Hamburg und Toulouse

- 2010

- Project Leader of Green Field Initiative

- since 2010

- Manager of Airbus Innovation Cell Germany,

today Head of Emerging Technology & Concepts Germany

Participation in professional societies and committees

- since 2013

- Member of the Scientific Advisory Board at the Fibre Institute Bremen, Prof. Axel Herrmann, University of Bremen

- since 2014

- Member of the Innovation Committee of the Hamburg Chamber of Commerce

- since 2014

- Member of the expert group of the BDLI, Committee - Business and Law

Prof. Dr.-Ing. Claus Emmelmann

- 29.11.1959

- Born in Hannover

- 1980 - 1986

- Studies of mechanical engineering at the Leibniz University of Hannover

- 1987 - 1988

- PhD student at the Institute of Production Engineering and Machine Tools (IFW) at the Leibniz University of Hannover

- 1988 - 1991

- Head of manufacturing technologies at Laser Zentrum Hannover e.V., Hannover

- 1991

- Graduation to Dr.-Ing. at the Leibniz University of Hannover, faculty Mechanical Engineering

- 1992 – 1995

- Sales manager and product manager, product area solid state lasers, Rofin Sinar Laser GmbH, Hamburg

- 1995 – 1997

- Export manager, exclusive USA and Japan, for CO², solid state and diode lasers, Rofin Sinar Laser GmbH

- 1997 - 1999

- Assistant head of sales at Rofin Sinar Laser GmbH

- 1999 - 2001

- Division manager solid state lasers at Rofin Sinar Laser GmbH

- since 2001

- C4-Professor at the Hamburg University of Technology (TUHH) and

Head of institute of Laser and System Technologies - 2001 - 2015

- Dean of „Gewerblich-Technische Wissenschaften“ at TUHH,

member of research groups at TUHH: maritime systems, aviation, medical engineering - since 2009

- CEO of Laser Zentrum Nord GmbH, Hamburg

Involvement in expert associations and committees

- Board member of HansePhotonik e.V., optical technologies

Council member of NORTEC – fair for production in northern Germany

Member Wissenschaftliche Gesellschaft Lasertechnik WLT e.V.

Dipl.-Ing. (FH) Frank Herzog

- 31.10.1971

- Born in Bamberg

- 1989 – 1992

- as an industrial Mechanic for equipment and fine mechanics; Siemens Healthcare, Erlangen

- 1992 - 1994

- College of Further Education, Bamberg

- 1994 – 1999

- Studied engineering at the University of Applied Science and Arts Coburg;

Semester abroad with a scholarship at the University of Huddersfield - 1999

- Final degree Dipl.-Ing. (FH)

- since 2000

- Foundation of the Concept Laser GmbH, Lichtenfels

President & CEO - 2014

- Foundation of the Concept Laser, Inc., Grapevine, Texas, USA

Chairman of the Board of Directors - 2014

- Member of the Evaluation Committee “Green Factory”

Honors:

- 2014

- Bayern Best 50 für Concept Laser, Auszeichnung als inhabergeführtes Unternehmen für Umsatzwachstum und Schaffung von Arbeitsplätzen

- 2014

- European CEO Award - Best CEO in the Additive Manufacturing Industry

Contact

Spokesperson

Dipl.-Ing. (FH) Peter Sander

Airbus Operations GmbH

Kreetslag 10

21129 Hamburg

Phone: + 49 (0) 40 / 74 35 22 97

E-Mail: peter.sander@airbus.com

www.airbus.de

Press

Heiko Stolzke

Airbus Operations GmbH

Kreetslag 10

21129 Hamburg

Phone: +49 (0) 40 / 74 37 30 16

E-Mail: heiko.stolzke@airbus.com

www.airbus.com

Careen Bock

LZN Laser Zentrum Nord GmbH

Am Schleusengraben 14

21029 Hamburg

Phone: +49 (0) 40 / 48 40 10 500

E-Mail: careen.bock@lzn-hamburg.de

www.lzn-hamburg.de

Dipl.-Kfm. Daniel Hund

Concept Laser GmbH

An der Zeil 8

96215 Lichtenfels

Phone: +49 (0) 9571 / 16 79 251

E-Mail: d.hund@concept-laser.de

www-concept-laser.de

A description provided by the institutes and companies regarding their nominated projects

New process engineering: layer by layer – components made from metals

3D printing with metals – ready for industrial series production

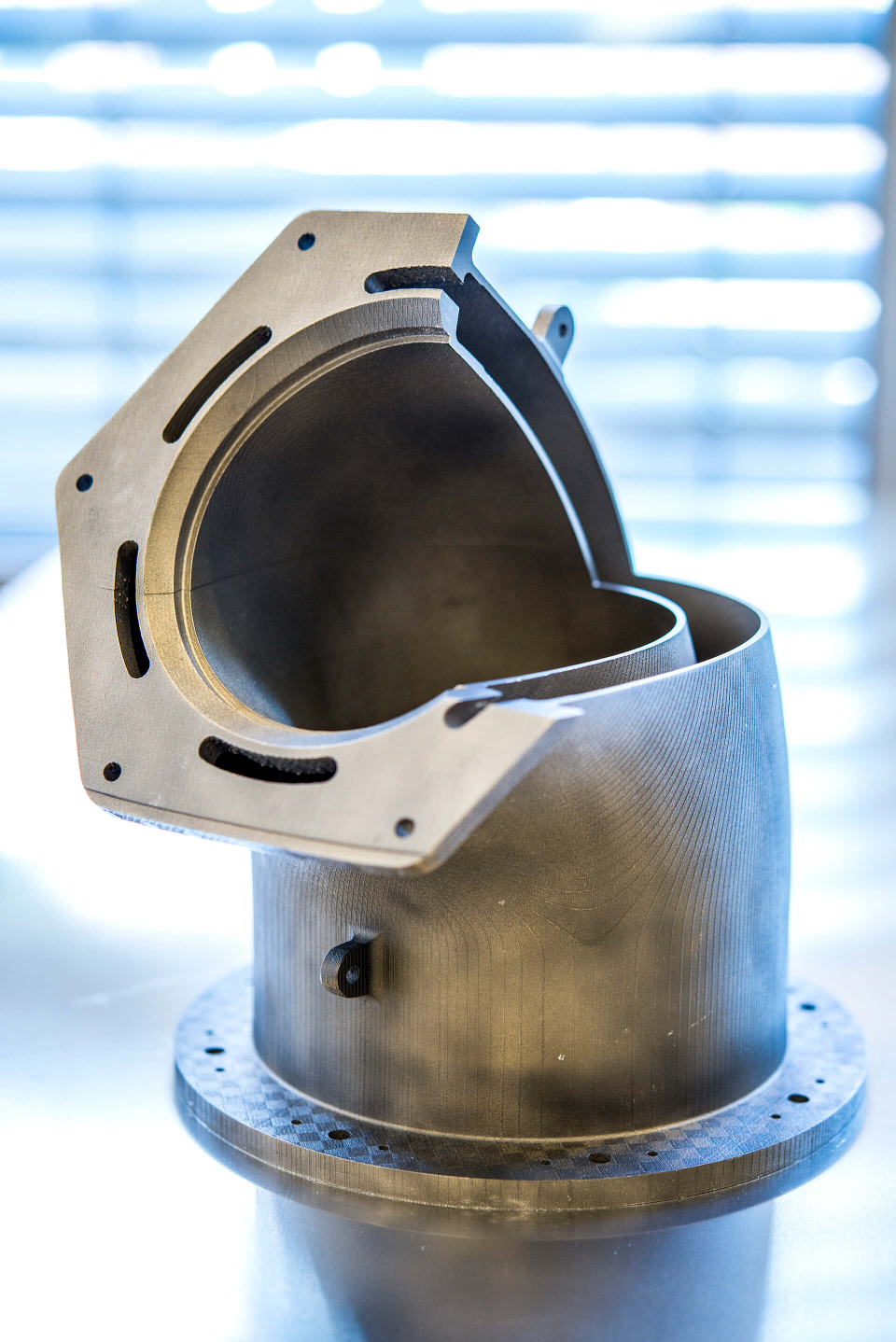

Working together to turn an idea into reality – that is the success that Airbus, LZN Laser Zentrum Nord, and Concept Laser have accomplished with their three-dimensionally printed component made from metal: a titanium cabin bracket.

Airbus – along with other branches of industry in Germany – has thus tapped into new production methods that offer far more possibilities than traditional manufacturing processes. With this new methodology, products are no longer being die-cut, milled, or saw-cut from a solid piece of material, but are instead built up layer by layer. That provides many benefits: material and energy consumption are significantly lower, which conserves resources and protects the climate. Also, the design engineers have more freedom in the design of the components. In addition, prototypes, single units, or small series of products become easy and inexpensive to produce.

Success team

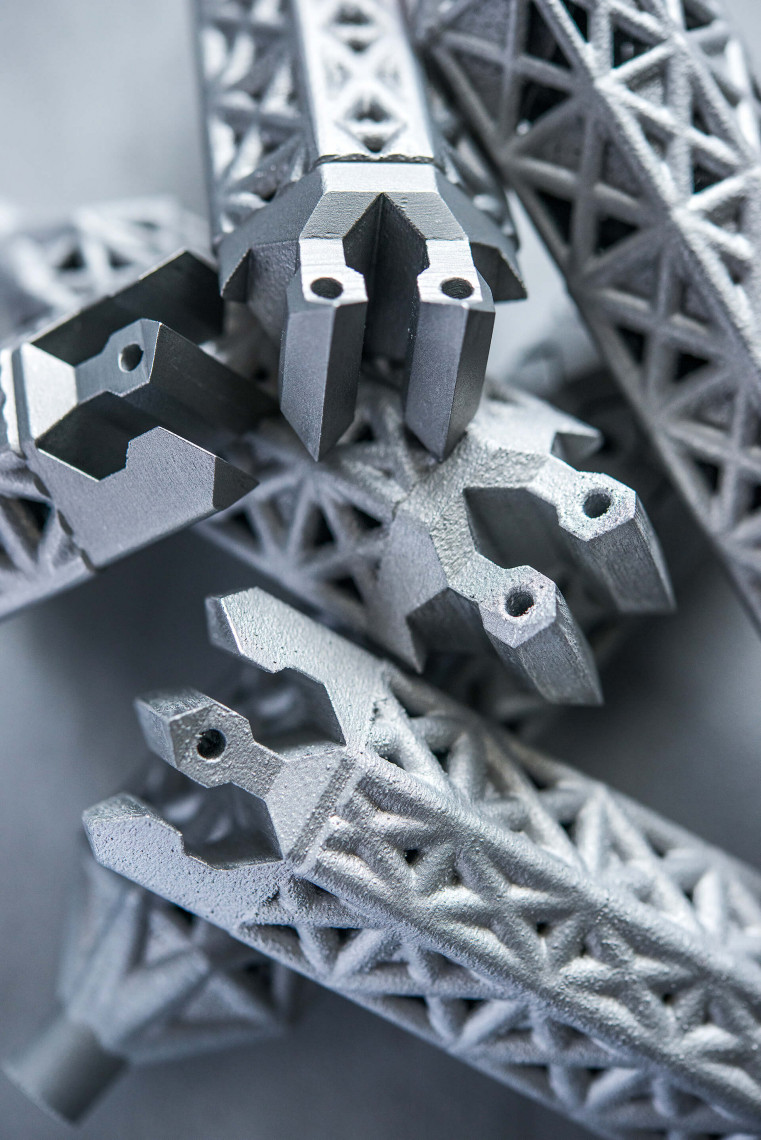

Aircraft construction places great demands on design and manufacturing. The challenge: designing complex aircraft components efficiently while saving on cost and protecting the environment as much as possible. Peter Sander, head of the Emerging Technologies & Concepts department at Airbus, Claus Emmelmann, CEO of LZN Laser Zentrum Nord and director of the Institute of Laser and System Technologies (iLAS) of the University of Technology Hamburg-Harburg (TUHH), as well as Frank Herzog, managing director of Concept Laser located at Lichtenfels in Upper Franconia, and their respective teams developed this method and saw it through to its industrial maturity. Airbus has used this jointly created process for the first time to produce a cabin bracket made from titanium. The part serves to attach the crew rest compartment on board the new A350 XWB long-range aircraft and has been in use since 2014.

The so-called "LaserCUSING®" is a "green technology" that not only reduces the environmental footprint of the manufacturing process but also shortens downtimes of the aircraft during maintenance: necessary spares can be printed on demand on site without delay.

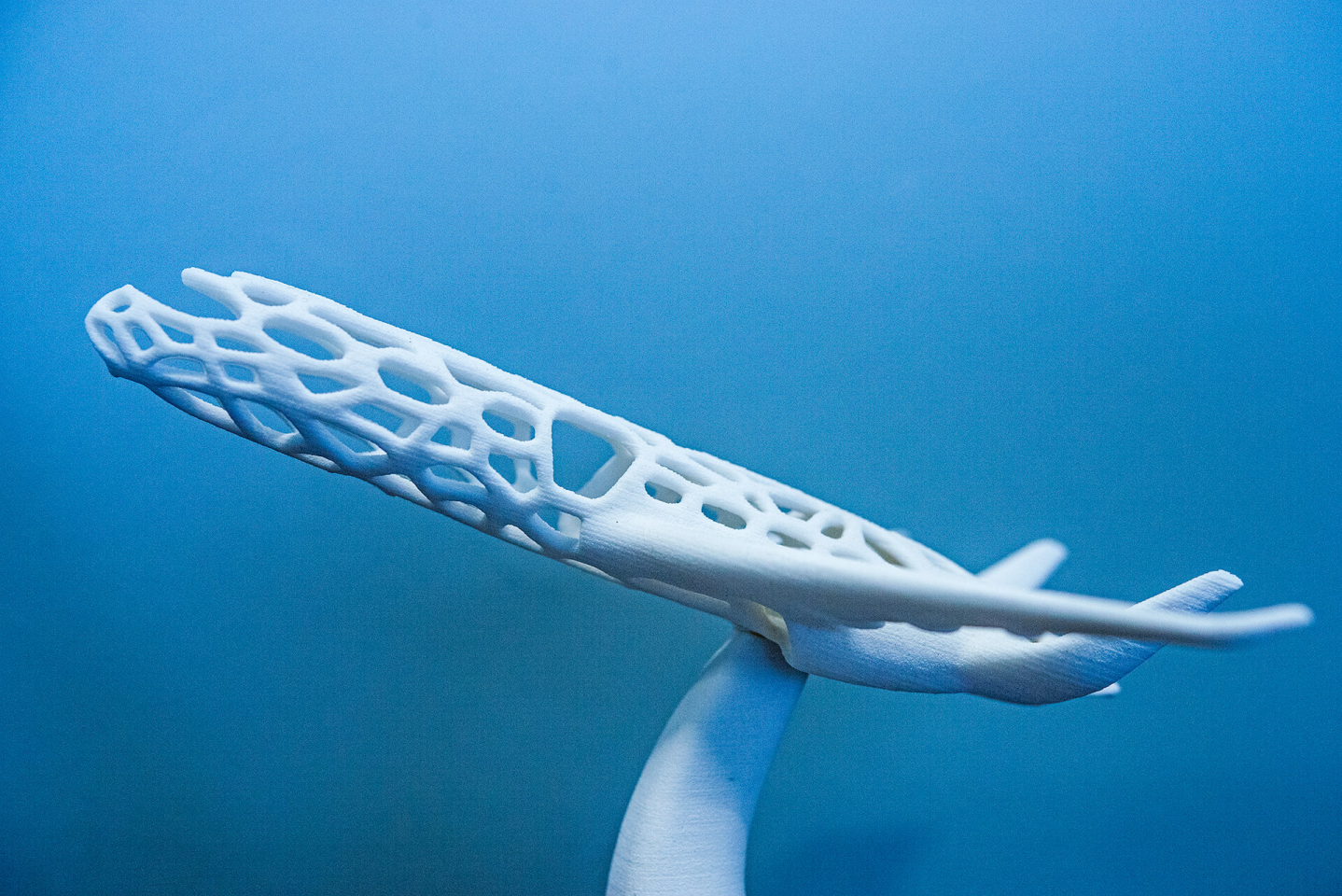

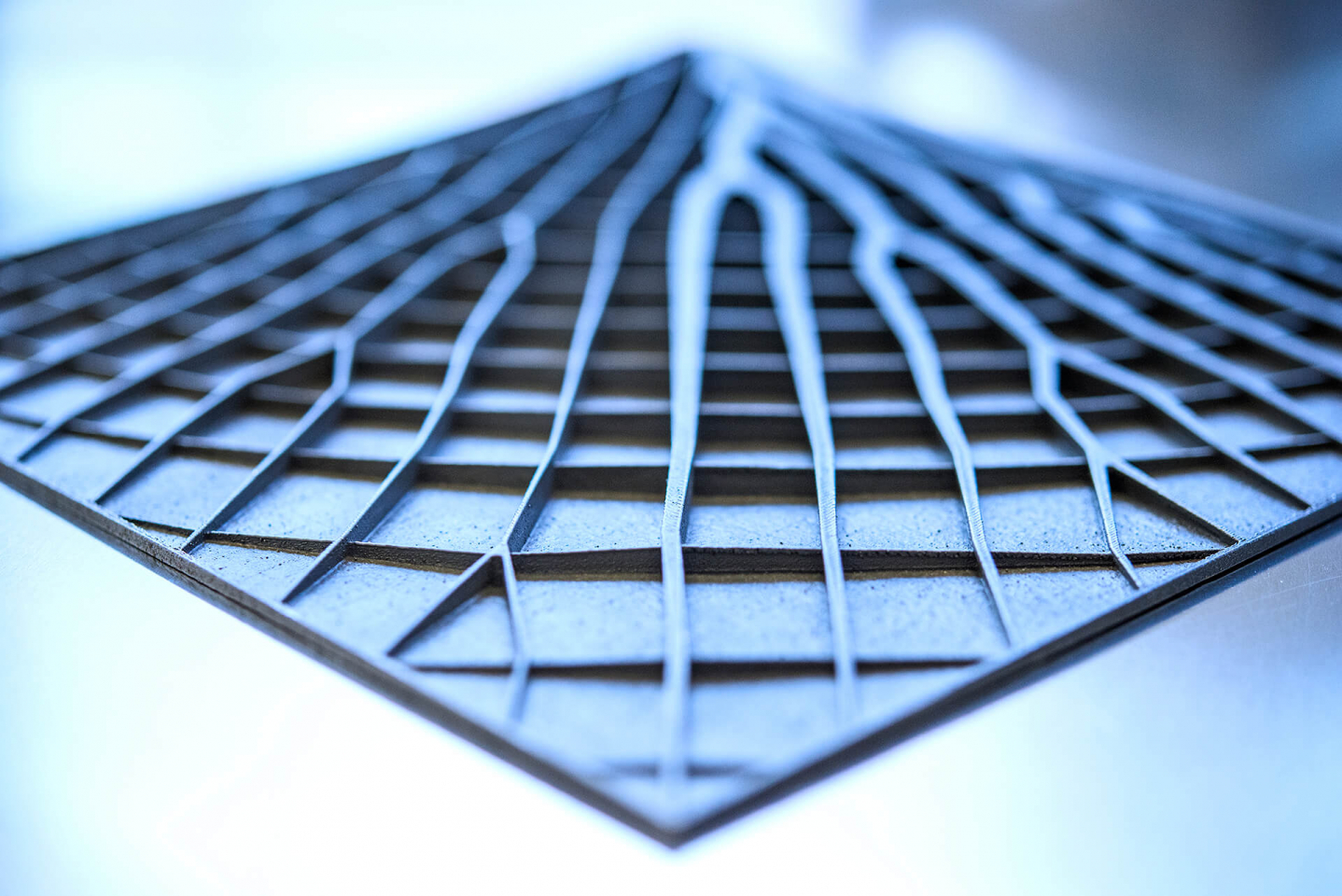

Airbus is planning to soon expand 3D printing to producing additional components – and to utilise the innovative process to implement novel design elements. This bionic design methodology, developed by LZN, makes it possible to base the shape of parts on patterns found in nature and thereby save up to 80 % in weight. The thus gained weight reduction contributes significantly to cutting the CO2 emissions of coming aircraft generations.

The process

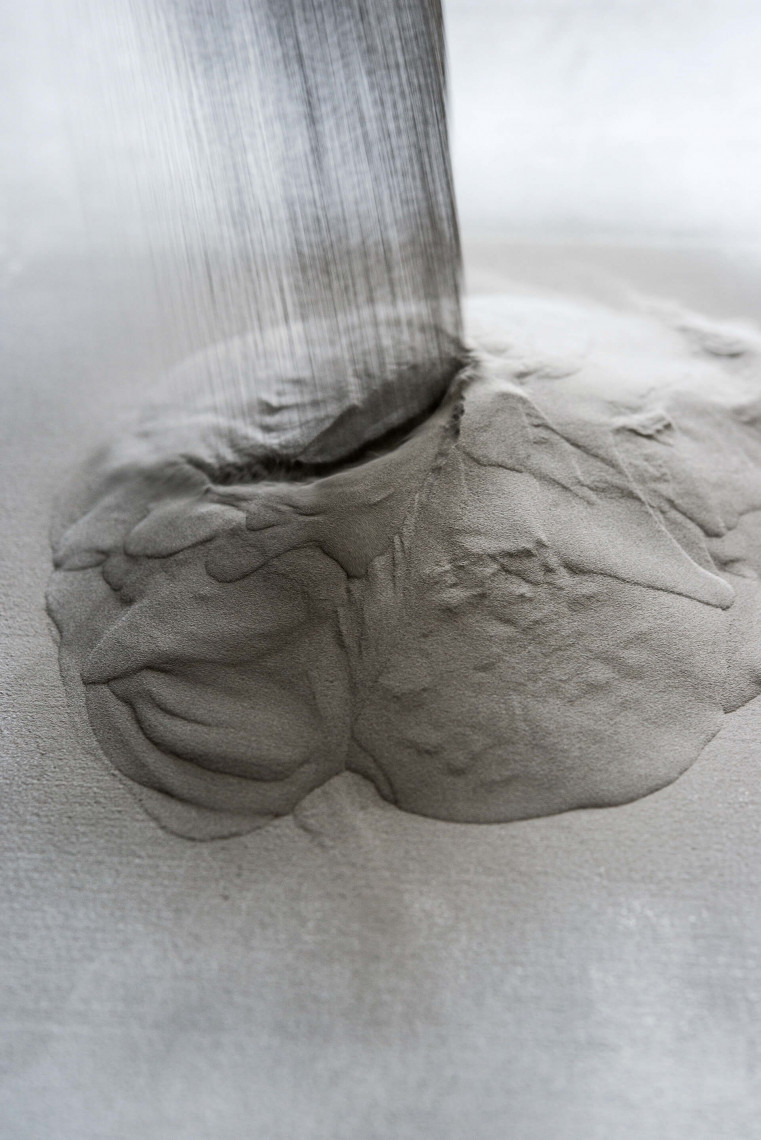

Until now, however, only certain materials were eligible for this "Additive Layer Manufacturing" method; plastics, for example, or easily meltable alloys. The new process can even use 3D printing to produce metal components that are highly resistant to mechanical and thermal stresses. The "LaserCUSING®" process is suitable for different types of steel, precious metals such as gold and silver alloys, and alloys containing titanium. The processing of titanium poses great challenges for both conventional manufacturing processes and the "LaserCUSING®" process, though. The intensive process development work performed by Laser Zentrum Nord and Concept Laser in close cooperation with Airbus is now allowing for the production of metallic components for aeronautical applications with assured quality levels.

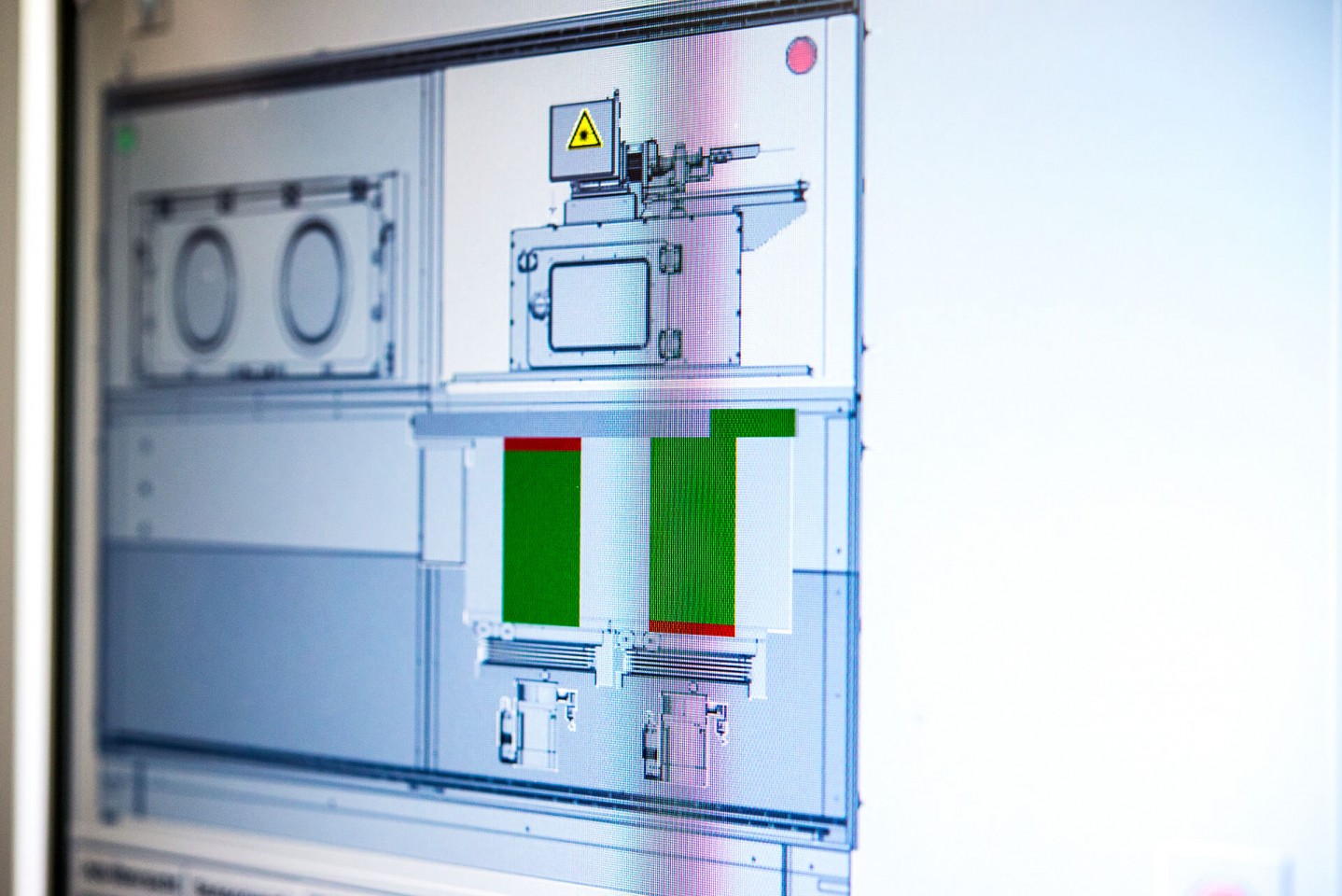

Metal powder is heated with the high-energy light from a fibre laser and thus melted. As it cools, the material solidifies. The laser covers the metal powder line by line, following a precise computer program and thereby gradually creates the desired shape. To build up the complete product, it is lowered a few dozen micrometres after completing each layer, after which the next layer is applied. A patented "stochastic exposure" control ensures that even components as large as they are needed for aircraft construction can be printed largely free from stresses.

Digital innovation

Core of the innovation is the fully digital nature of the manufacturing process. This allows for the 3D printer to be integrated in a continuous digital process chain in which the individual manufacturing steps including material logistics and quality inspections run automatically and are perfectly aligned. This revolutionary concept, the development and implementation of which is being advanced under the leadership of researchers and companies in Germany, embodies the Industry 4.0 principle.

Good prospects

The significance of 3D printing of metallic products far exceeds the bounds of aeronautical engineering. The technology is anticipated to find applications in many areas such as Germany's key industries of automotive engineering, mechanical engineering and plant construction, and medical technologies, where it is set to replace or supplement conventional manufacturing methods. Specialists expect the market for 3D printing to grow to up to five times its current volume over the coming years.

About Airbus:

Airbus is the leading aircraft manufacturer to offer the most cutting edge and comprehensive family of commercial aircraft available on the market. Airbus products cover the complete capacity range from 100 to significantly more than 500 seats. As a pioneer of innovative technologies, Airbus is offering aircraft with some of the lowest cost and noise factors in the world. To date, Airbus has sold more than 15,600 aircraft to more than 380 customers worldwide and has already delivered more than 9,100 of them (status: June 2015). The comfortable order backlog is currently running at almost 6,400 aircraft, which are scheduled for delivery over the coming years. Airbus employs roughly 55,000 people from approx. 100 different countries. The global company has design and manufacturing facilities in France, Germany, the United Kingdom, and Spain, as well as subsidiaries in the USA, China, Japan, India, and the Middle East. In addition, Airbus operates spares and training centres in Europe, the USA, and Asia, and supports Airbus customers with around-the-clock customer services to maximise profitability of their fleets.

Contact information for Airbus in Germany:

Press contact: Heiko Stolzke, Manager Media Relations, phone: +49 40 743 73016, e-mail: heiko.stolzke@airbus.com

About Laser Zentrum Nord:

LZN Laser Zentrum Nord GmbH (LZN) was founded in 2009 as a spin-off of the Institute of Laser and System Technologies (iLAS) of the University of Technology Hamburg-Harburg (TUHH). As a competence centre for laser technologies, LZN GmbH considers itself a bridge between basic scientific research and industrial application and creates trend-setting impulses for companies to sustainably enhance their competitive strength. Their research, development, and consulting activities comprise the end-to-end process chain from the analysis to the finished prototype. LZN cooperates with companies from the automotive, naval architecture, aircraft manufacturing, medical technologies, tooling, and mechanical engineering industries. Components are developed or optimised and implemented with titanium, steel, stainless steel, aluminium, and composites based on the theme "Engineering in Light – Photonic Solutions for Resource Efficient Products". The "Light Alliance" industrial working group offers companies the opportunity of learning and realising the theory and practice of "Engineering in Light" based on component demonstrators. Taking professional partners from industry and research, the participants can thus tap into the future market of 3D laser production engineering.

Contact information for Laser Zentrum Nord:

Press contact: Careen Bock, Marketing Manager, phone: +49 40 484 010 500, e-mail: careen.bock@lzn-hamburg.de. For further information on LZN Laser Zentrum Nord GmbH, please visit: www.lzn-hamburg.de and www.light-alliance-hh.de

About Concept Laser:

Concept Laser GmbH, headquartered at Lichtenfels (Germany), has been a leading innovator in the field of laser melting technologies since its founding in 2000, offering the patented LaserCUSING® process for applications in many industries.

The term LaserCUSING®, a combination of the C from CONCEPT Laser and the word FUSING (to fully melt), describes the technology: the fusing process generates components layer by layer using 3D CAD data and makes it possible to manufacture complex component geometries without tooling. This way, parts can be produced that are difficult or even impossible to achieve through conventional manufacturing methods.

The Concept Laser systems process a wide variety of metal powder materials, e.g. stainless steel, cobalt-chromium alloys, nickel-base alloys, titanium alloys, or even precious metals. The high quality standards, level of experience, and successful track record of Concept Laser guarantee reliable and cost-effective solutions with proven performance in everyday production.

Contact information for Concept Laser:

Press contact: Dipl.-Kfm. Daniel Hund, Head of Marketing, phone: +49 9571 1679 251, e-mail: d.hund@concept-laser.de

The right to nominate outstanding achievements for the Deutscher Zukunftspreis is incumbent upon leading German institutions in science and industry as well as foundations.

The project "3-D printing in commercial aircraft engineering – a manufacturing revolution is taking off" was nominated by BDI - Federation of German Industries.

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache