Nominee 2014

Horizontales Bandgießen

Dr. Ulrich Grethe, Burkhard Dahmen and Prof. Dr. Karl-Heinz Spitzer have found the solution. They are responsible for the development of a new steel casting process that needs far less energy and raw materials than in the past. At the same time, the innovative method is especially cost-effective - and above all presents an opportunity to expand considerably the useful range of steel properties. Ulrich Grethe is CEO of Salzgitter Flachstahl GmbH, Burkhard Dahmen is CEO of SMS Siemag AG, Karl-Heinz Spitzer is the chair for Metallurgical Process Engineering at the Institute of Metallurgy at Clausthal University of Technology.

Steel is both a traditional material as well as ultra modern and, due to its outstanding and versatile properties, demand is very high in many fields of industry. The best example is in automotive engineering. To respond to the challenges such as a further lowering of fuel consumption in vehicles, industry has come to rely on innovative special steels such as high strength and ductility (HSD®) steel: it contains a higher percentage of manganese which makes the steel a ductileand extremely hard. The material makes it possible to manufacture even safety-critical components such as seats, door impact bars and bumpers much lighter. However, these types of steel cannot be produced by means of conventional casting technologies, such as continuous casting.

more details

Resumes

Dipl.-Ing. Ulrich Grethe

- June 30, 1961

- Born in Duisburg, Germany

- 1981

- School leaving examination

- 1981 – 1988

- Study of metallurgy and materials science at the Clausthal University of Technology

- 1988

- Diploma thesis at the Institute of Metallurgy of TU Clausthal

- 1989

- Trainee at Stahlwerke Peine - Salzgitter AG

- 1990 – 2000

- Various managerial positions at the Salzgitter melt shop of Preussag Stahl AG, later Salzgitter AG

- 2000 – 2005

- Melt shop operations manager at Salzgitter Flachstahl GmbH

- 2005

- Plant manager at Salzgitter Flachstahl GmbH

- Since 2006

- General Manager Operations, Member of the Management Board at Salzgitter Flachstahl GmbH

- 2010

- Member of the Management Board of Salzgitter Stahl GmbH

Chairman of the Management Board of Salzgitter Flachstahl GmbH - 2014

- Head of the Strip Steel Business Unit of Salzgitter AG, member of the Group Management Board

Collaboration in professional associations and committees

- Since 1998

- Board member of the Association of Friends of Clausthal University of Technology

- Since 2006

- Board member of VDEh and the German Steel Association

- Since 2006

- Member of the Board of Administration of BFI (Betriebsforschungsinstitut of VDEh)

- Since 2013

- Board member of FOSTA - Research Association for Steel Application and the Research Committee

Dipl.-Kfm. Burkhard Dahmen

- February 15, 1964

- Born in Düsseldorf, Germany

- 1984

- School leaving examination

- 1986 – 1990

- Study of business administration at the University of Münster, Germany, and at the University of Warwick, UK

- 1990

- Diploma thesis at the Institute of Industrial Plant and Systems Technologies, Münster

- 1990

- Specialist for project and contract financing at SMS Schloemann Siemag AG, Düsseldorf

- 1992

- Sales specialist at SMS Schloemann-Siemag AG, Düsseldorf

- 1994

- Head of SMS Liaison Office in Beijing, China

- 1997

- Head of Central Marketing / Commercial Manager Sales and authorized representative at SMS Schloemann-Siemag AG

- 2002

- General Manager of SMS Sidernaval, Bilbao / Spain

- 2004

- Appointment to the Board of Management of SMS Siemag AG

- 2012

- Chairman of the Board of Management of SMS Siemag AG, Düsseldorf and Hilchenbach; member of the Board of Management of SMS Holding GmbH, Düsseldorf

- Since 2014

- Spokesman of the Board of Management of SMS Holding GmbH, Düsseldorf

Collaboration in professional associations and committees

- Since 2006

- Vice Chairman of Nah- und Mittelost-Verein e.V., Berlin

- Since 2011

- Chairman of the Committee on External Economic Relations of the Düsseldorf Chamber of Commerce

Prof. Dr.-Ing. Karl-Heinz Spitzer

- February 21, 1956

- Born in Lippstadt, Germany

- 1974

- School leaving examination

- 1974 – 1980

- Degree in mathematics at Bielefeld University

- 1980 – 1985

- Research associate at the Institute of Metallurgy of TU Clausthal

- 1985

- PhD under Prof. Dr.-Ing. K. Schwerdtfeger at the Institute of Metallurgy of TU Clausthal

Doctoral thesis: "Mathematische Modellierung zum elektromagnetischen Rühren beim Stranggießen" (mathematical modeling of electromagnetic stirring in continuous casting)

- 1985 – 2002

- Senior assistant professor at TU Clausthal

- 2002

- Habilitation at TU Clausthal in metallurgy

Post-doctoral thesis: "Mathematische Modelle zur Entwicklung und Optimierung metallurgischer Prozesse" (mathematical models for developing and optimizing metallurgical processes) - Since 2002

- Full professor for Metallurgical Process Technology (C4) at TU Clausthal

Collaboration in professional associations and committees

- Since 2002

- Member of VDEh Grundlagenausschuss

- 2004 – 2012

- Materials Science Review Board of DFG

Contact

Spokesperson

Dipl.-Ing. Ulrich Grethe

Salzgitter Flachstahl GmbH

Eisenhüttenstr. 99

38239 Salzgitter

Phone: +49 (0) 5341 / 21 23 21

E-Mail: grethe.u@salzgitter-ag.de

Press

Bernhard Kleinermann

Salzgitter AG

Eisenhüttenstr. 99

38239 Salzgitter

Phone: +49 (0) 5341 / 21 23 00

E-Mail: kleinermann.b@salzgitter-ag.de

www.salzgitter-ag.com

Dr. Thomas Isajiw

SMS GmbH

Eduard-Schloemann-Straße 4

40237 Düsseldorf

Phone: +49 (0) 211 / 88 14 127

E-Mail: thomas.isajiw@sms-group.com

www.sms-group.de

Christian Ernst

Technische Universität Clausthal

Adolph-Roemer-Straße 2a

38678 Clausthal-Zellerfeld

Phone: +49 (0) 5323 / 72 39 04

E-Mail: christian.ernst@tu-clausthal.de

www.tu-clausthal.de

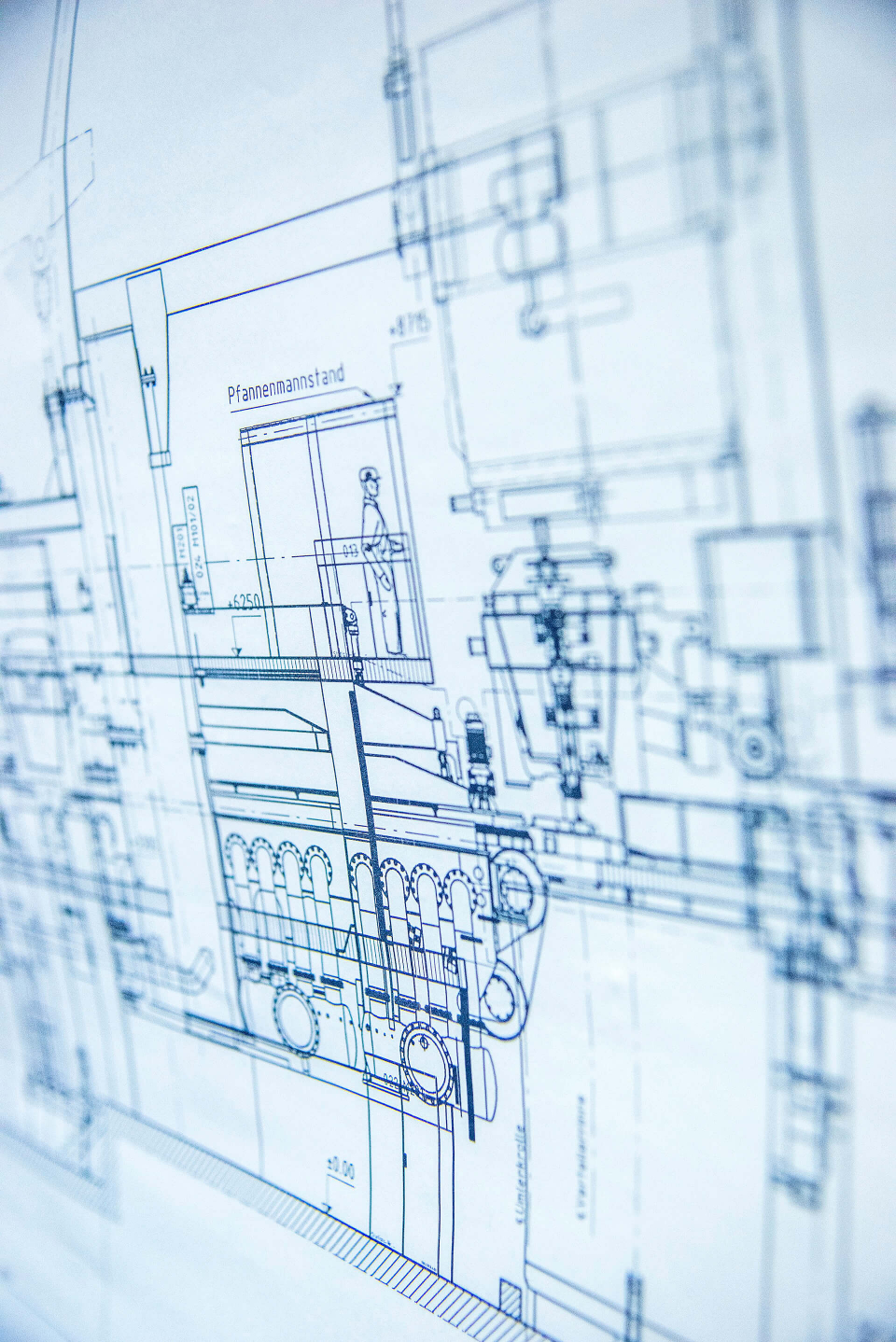

A description provided by the institutes and companies regarding their nominated projects

New lightweight construction steels using industrial belt casting technology

The dream of casting thin steel!

In a close cooperation between science and industry, Salzgitter Flachstahl GmbH, SMS Siemag AG and the Clausthal University of Technology have succeeded in scaling up the horizontal belt casting of steel, from fundamental research to industrial use.

The technology of thin casting takes its lead from the dream and vision of producing rolled steel products, ideally seamlessly directly from molten material. This saves energy and resources, conserves the environment and opens up the potential for manufacturing steel products even more flexibly and cost efficiently in the future.

Over the past ten years, Professor Karl-Heinz Spitzer has made vital headway with the fundamental process technology at TU Clausthal with the support of the two industrial partners. The important foundations for this were also laid in the context of several research initiatives, one being the recent ReBand project of Bundesministerium für Bildung und Forschung (Federal Ministry for Education and Research). Ulrich Grethe (Salzgitter Flachstahl GmbH) and Burkhard Dahmen (SMS group) together assumed a leading role in realizing the world's first industrial facilities during the period from 2010 to 2012. This courageous step was also funded by the German Federal Ministry for the Environment, Nature Conservation and Nuclear Safety in the context of environmental protection aid.

Since then, the two parties, drawing on the scientific support of Professor Spitzer, have both coordinated the break-in run that has already produced evidence of its sustainability for industrial use. In addition, they are responsible for launching the process technology in the market and selling the belt casted steel products.

This special process technology also opens up the prospect of producing innovative high-performance materials, which, up until now, has been impossible or extremely difficult. A prime example is an entirely new generation of lightweight construction steels that are extremely resilient while exhibiting high ductility, thereby essentially combining two generally irreconcilable material properties in conventional steel as well as other metals. Ideally shaped and highly stress resistant components can now be produced that for instance make vehicles lighter, but also safer.

The horizontal belt casting of steel addresses the key challenges of a cutting-edge, forward-looking process technology and material production. An additional aspect is the significant stimulus for securing the sustainability of steel-intensive industries in global competition. This applies not only to the future of Germany's steel industry, but also to its traditionally strong automotive and machinery industries, as well as plant engineering.

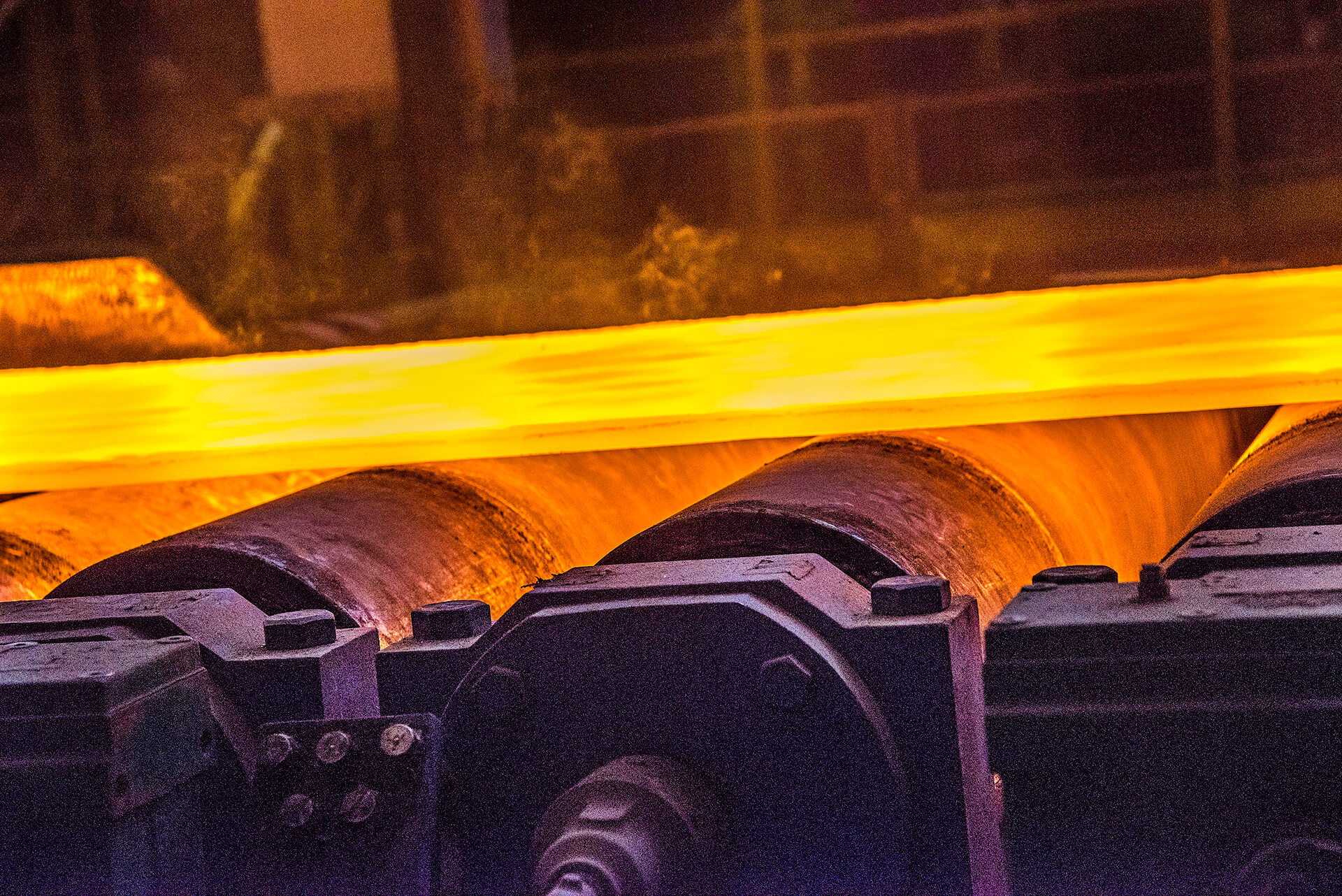

This is how it works!

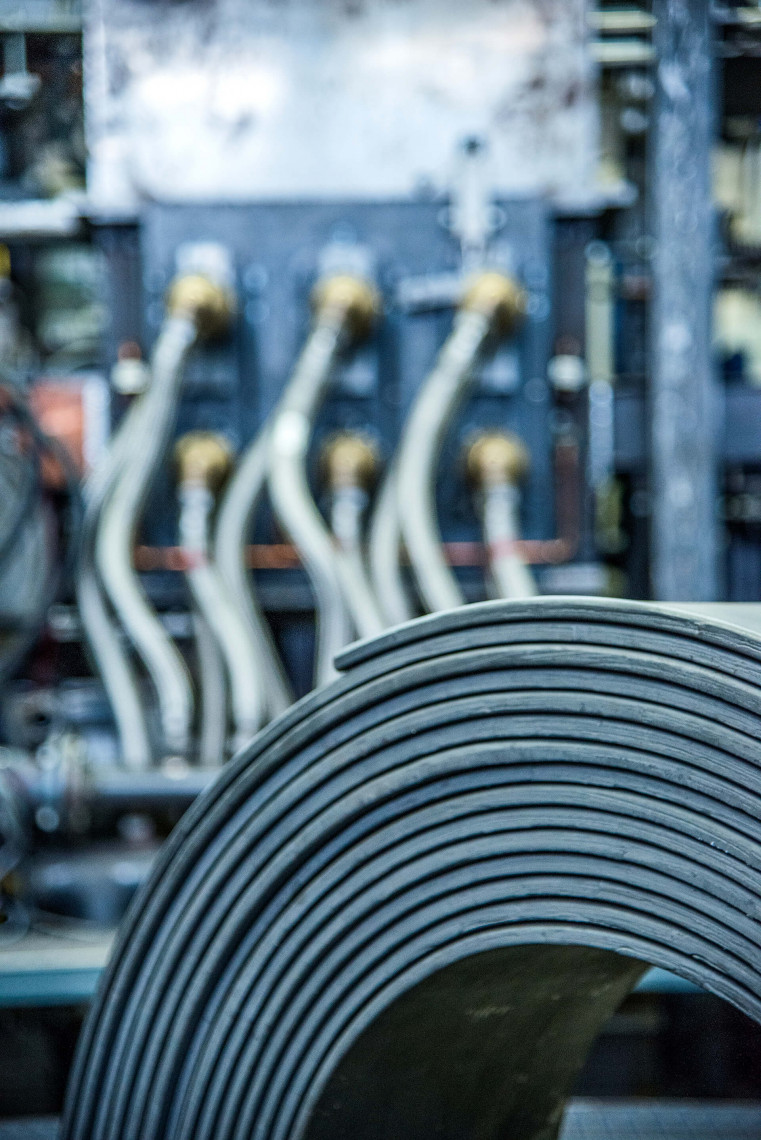

In contrast to the conventional continuous casting of thick ingots, horizontal belt casting allows the molten steel to be poured around 20 times more thinly on to an intensively cooled conveyor belt moving at casting speed. The near-net-shape casting of the material in a thickness of around 15 mm cuts off the need for reheating and rolling steps on its way to becoming sheet or strip steel.

The horizontal melt flow facilitates a good cooling process that exerts little mechanical strain on the hot steel. The belt caster and product move at the same speed, and the lubricants customarily required can be dispensed with. The cooling water does not come into contact with the cast product and is reused without further treatment.

The rapid cooling of the material has a positive effect on the casting quality. The casting thickness is, however, sufficient to allow the desired product properties to be securely achieved after rolling. Essentially these process advantages are what have made the production of a wide range of new, high grade and particularly sophisticated steel materials possible in the first place.

High strength matched by high ductility!

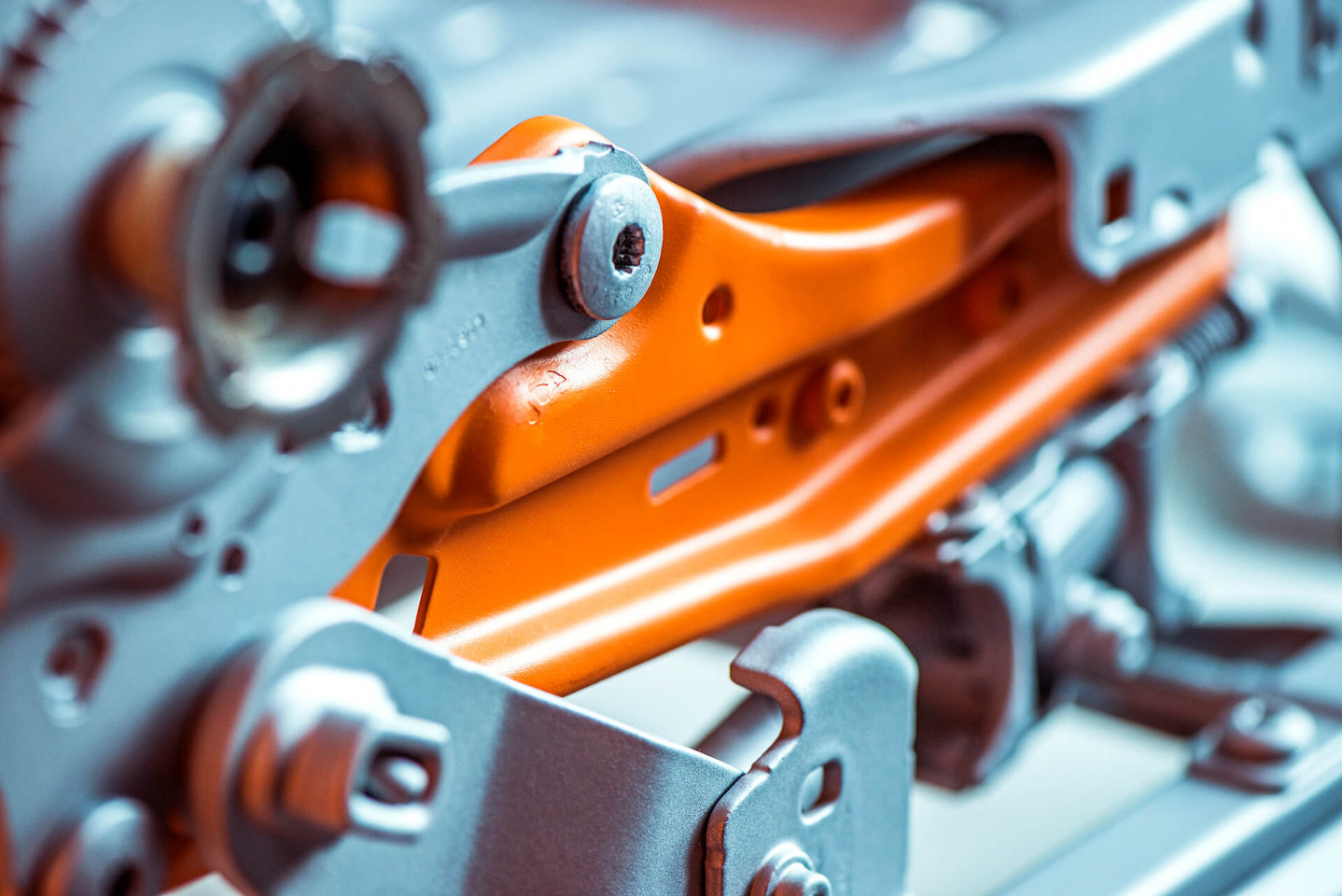

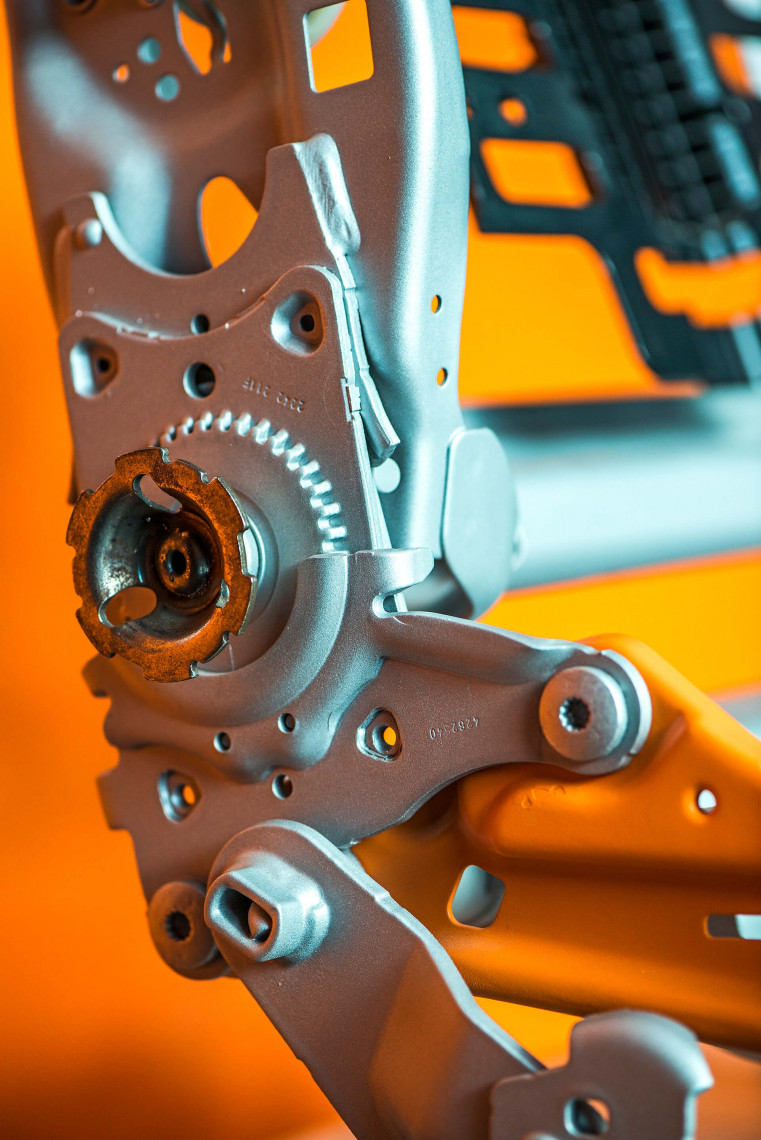

The advantages of horizontal belt casting are put to use, for instance, in the production of an entirely new generation of lightweight HSD® steels. HSD® stands for high strength and ductility and designates steels with higher manganese content and small additions of aluminum and silicon. The product properties can be individually customized to suit the application in question. This solution also harbors deformation reserves which come into their own under different exposures to stress – take colliding vehicles or very low temperatures, for example. New design and lightweight construction potential can be tapped, also in the non-automotive sector, which opens the door to further energy savings and resource efficiencies.

HSD® steels are particularly suitable for automotive lightweight construction, especially heavily stressed components with complex geometries in the bodywork, interior and chassis. Automotive engineers enjoy greater scope for design without having to additionally heat up the material. In the weight-optimized utilization of materials, both the number of individual components and operations in the forming process can be reduced in production.

Examples include components relevant to safety that are currently being tested, such as bumpers, door impact bars, car seats and load-bearing bodywork components. Weight savings of 17% to 38% can be made compared with today's serial production.

Promising outlook

Belt casting technology and high-performance steels have a doubly positive impact on sustainable environmental protection. The consumption of energy during the casting and hot rolling stages can be reduced in the future by around one third after full process integration. In addition, the weight advantage of belt casted lightweight construction steels reduces the amount of gas needed to run a vehicle.

The industrial-scale introduction of the belt casting technology at the Peine steelworks is progressing steadily and may be the genesis of a broader industrial breakthrough. The belt casting process is decidedly compelling due to its economical and compact design and comparatively low capital expenditure. The SMS group has the opportunity of developing this innovative casting technology into an industrial production method suitable for conventional and special steels and selling it successfully.

Moreover, numerous ongoing product development projects have shown a great interest in the belt casted lightweight steels from Salzgitter. The range potential of steel products achievable through this process currently defies prediction. Salzgitter Flachstahl GmbH is already working on other structural and functional materials that are perfectly suited to belt casting.

Salzgitter AG

With external sales of € 9 billion in 2013, a crude steel capacity of approximately 8 million tons and a workforce of around 25,000 employees, Salzgitter AG ranks as one of Europe’s leading steel and technology groups. The company operates cutting-edge and resource efficient production sites in Germany and abroad. It comprises more than 200 subsidiaries and associated companies and is divided up into the five business units of Strip Steel, Plate/Section Steel, Trading, Energy and Technology, all operating under the management of Salzgitter AG as the holding company.

Salzgitter Flachstahl GmbH is the Salzgitter Group's largest steel subsidiary. Some 4.4 million tons of crude steel were produced in 2013, with annual sales of € 2.7 billion. Salzgitter Flachstahl currently has a workforce of 5,769 employees. Its most important customers include vehicle manufacturers, their suppliers, standard and large-diameter tubes manufacturers, re-rollers and the construction industry. The company fields a wide range of hot and cold rolled along with surface-finished products. It focuses particularly on innovative and customized production processes and material solutions destined, for example, for special forming processes and extremely sophisticated safety and exterior components of automotive construction.

www.salzgitter-ag.com

Press contact: Bernhard Kleinermann, +49 (0)5341 21 2300, kleinermann.b@salzgitter-ag.de

SMS group

The SMS group is a global leader in the field of metallurgical machinery and plant engineering for the processing of steel and nonferrous metals. It employs more than 13,800 employees worldwide and generates sales of around € 3.5 billion. The Group consists of companies operating internationally headed by SMS Holding GmbH and is divided into the business areas of SMS Siemag, SMS Meer as well as associated industrial companies.

Around 60 percent of the SMS group's total sales are generated by SMS Siemag whose product program covers the process chain with plants for the steel, aluminum and nonferrous metals processing industry, from iron- and steelmaking technology, continuous casting techniques for strip products and rolling mills right through to surface finishing lines for hot- and cold-rolled strip, including electrics and automation as well as the relevant services.

www.sms-group.de

Press contact: Dr. Thomas Isajiw, +49 (0)211 881-4127, thomas.isajiw@sms-group.com

Clausthal University of Technology

Innovative, industry-oriented, international. Engineers and scientists have been trained for more than 230 years in Clausthal. Originally a mining academy, the Clausthal University of Technology held in high national and international regard places particular emphasis on technologies of the future. Research and education at Clausthal University of Technology are currently focused on Energy and Raw Materials, Materials Science as well as Simulation and Complex Systems. Since the beginning of 2009, Clausthal University of Technology, the Technische Universität Braunschweig and Leibniz Universität Hannover have combined their engineering and scientific expertise under the Niedersächsische Technische Hochschule, NTH. The aim of this cooperation is to establish an equal footing with Germany's leading technical universities. With around 4,600 students and some 1,050 employees, TU Clausthal is one of the most important economic factors in the Harz.

www.tu-clausthal.de

Press contact: Christian Ernst, +49 (0)5323 72 3904, christian.ernst@tu-clausthal.de

The right to nominate outstanding achievements for the Deutscher Zukunftspreis is incumbent upon leading German institutions in science and industry as well as foundations.

The project "Horizontal belt casting of steel – resource-conserving production of new high-performance materials" was nominated by BDI – Bundesverband der Deutschen Industrie e.V..

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache