Winner 2014

Lebensmittelzutaten aus Lupinen

Dr. Stephanie Mittermaier, Dr.-Ing. Peter Eisner and Dipl.-Ing. Katrin Petersen focused their research on lupins. They developed a process to produce vegetarian and vegan foods using these domestically grown plants, which are hardly distinguishable from animal-based products in taste and mouthfeel. They are an ideal alternative to soybeans. Stephanie Mittermaier is head of the Functional Ingredients business unit at the Fraunhofer Institute for Process Engineering and Packaging IVV in Freising, Peter Eisner is head of the IVV department Process Development for Plant Raw Materials and Food Process Development, Karin Petersen is Managing Director of Prolupin GmbH in Grimmen.

Consumption of plant-based products has the advantage that much less agricultural acreage is needed for their cultivation. Every kilogram of animal-based protein produced uses approximately five times the amount of land required to produce one kilogram of plant-based proteins.

more details

Resumes

Dr. rer. nat. Stephanie Mittermaier

- 29.08.1981

- born in Augsburg

- 2001

- Abitur at Gymnasium Wertingen

- 2001 - 2006

- Studies „Technology and Biotechnology of Food“ at TU München - Weihenstephan

- 2006

- Degree: Dipl.-Ing.

- Since 2006

- Member of the Scientific Staff at Fraunhofer-Institute for Process Engineering and Packaging IVV in Freising

- 2013

- Doctorate and title Dr. rer. nat. at Friedrich-Alexander-Universität Erlangen-Nürnberg

- Since 2013

- Head of Business Unit „Functional Ingredients“ at Fraunhofer-Institute for Process Engineering and Packaging IVV in Freising

Dr.-Ing. habil. Peter Eisner

- 15.04.1965

- born in Neuwied

- 1984 - 1991

- Studies in Mechanical Engineering and Process Engineering at Technical University Munich

- 1991

- Degree: Diplom-Ingenieur

- 1991 - 1996

- Scientist at the Institute of Water Quality Control and Waste Management, Technical University Munich

- 1997

- Degree: Doktor-Ingenieur

- Since 1996

- Employee at Fraunhofer Institute for Process Engineering and Packaging (IVV) in Freising-Weihenstephan

- 2001 - 2006

- Business Field Manager “Biogenic Raw Materials” at Fraunhofer IVV

- 2005 - 2006

- Business Field Manager Food Ingredients at Fraunhofer IVV

- Since 2006

- Head of Department Process Development at Fraunhofer IVV

- 2010

- CEO of Prolupin GmbH

Awards

- 2007

- Fraunhofer Prize "Human-Centered Technology" for the Development of a modified Method for the Production of low-fat Sausages with a Fat Content less than 3%

- 2009

- Nomination to „Fraunhofer Vintage Class”. From 2011 to 2013 speaker of Vintage Class.

- 2011

- “Deutscher Rohstoff-Effizienzpreis” of the Federal Minister for Economic Affairs for the Development of a Polymer based Metal Grinding Lubricant free of Mineral Oil

- 2012

- “Joseph von Fraunhofer Preis” for the Development of a Polymer based Metal Grinding Lubricant free of Mineral Oil

Dipl.-Ing. agr. Katrin Petersen

- 26.04.1969

- Born in Berlin

- 1988

- Abitur combined with professional training as plant breeder in Böhnshausen/Harz

- 1989 - 1994

- Studies in Agricultural Science at the Humboldt Universität Berlin

- 1994

- Degree: Dipl.-Ing. agr.

- 1994 - 1995

- EU Consultant at the Agency of Renewable Ressources (FNR) e.V., Gülzow

- 1998 - 2003

- Administration of information systems at the Mecklenburg-Western Pomeranian Agency for the Environment, Nature Conservation and Geology, Güstrow

- 2004 - 2010

- Head of the Competence and Foundation Center for modern agricultural biotechnology in Groß Lüsewitz and Project manager at the BioCon Valley GmbH

- Since 2011

- CEO of Prolupin GmbH, Grimmen

Contact

Spokesperson

Dr. Stephanie Mittermaier

Fraunhofer-Institut für Verfahrenstechnik und Verpackung IVV

Giggenhauser Str. 35

85354 Freising

Phone: +49 (0) 8161 / 49 14 12

E-Mail: stephanie.mittermaier@ivv.fraunhofer.de

www.ivv.fraunhofer.de

Press

Karin Agulla

Fraunhofer-Institut für Verfahrenstechnik und Verpackung IVV

Giggenhauser Str. 35

85354 Freising

Phone: +49 (0) 8161 / 49 11 20

E-Mail: karin.agulla@ivv.fraunhofer.de

www.ivv.fraunhofer.de

Beate Koch

Fraunhofer-Gesellschaft

Hansastraße 27c

80686 München

Phone: +49 (0) 89 / 12 05 13 00

Mobil: +49 (0) 173 / 37 48 838

E-Mail: beate.koch@zv.fraunhofer.de

www.fraunhofer.de

A description provided by the institutes and companies regarding their nominated projects

Coupled with a steadily growing competition for available arable land to produce food, feed and energy plants, the global population of 9 billion people projected for 2050 will put the food supply at risk in several regions. The consumption of higher quantities of plant based products instead of milk, egg or meat products is important as it will contribute to a sustainable supply of the world population with safe, healthy and well tasting food. Thus, for example for the production of 1 kg of meat protein a total quantity of 7 to 16 kg of grains or soy meal is required. With this amount of plant proteins the number of people, who can be fed, is 10 times higher than with 1 kg of meat.

However, in countries like Germany or USA a reduced consumption of animal derived products can only be achieved if plant based products reveal similar taste and flavor profiles as their animal based counterparts. However, similar flavor profiles of plant based products were not achieved yet, despite considerable research efforts. Commercially available proteins from canola, soy, pea or potato revealing similar properties as egg or milk proteins in food can be produced in industrial scale, but the taste and flavor of the food products with incorporated plant proteins are altered significantly. The typical plant associated flavor attributes like bitter, beany or green/grassy impair the taste of final products in a way that the incorporation of these proteins is limited to mostly intensively seasoned foods like sausages or whole grain bread.

Domestic lupine seeds – being free from genetically modified organisms – are promising raw materials for the production of food ingredients. Lupines are often cultivated as catch crop on organic farmland due to their ability to enhance soil conditions. These grain legumes can also deliver good yields on sandy soils and therefore, are not competing with other grains like maize, rapeseed or wheat as these crops are not able to provide acceptable yields on such soils. However, food ingredients produced from lupine seeds also exhibited green/grassy or beany flavors until now, which limited their application in food.

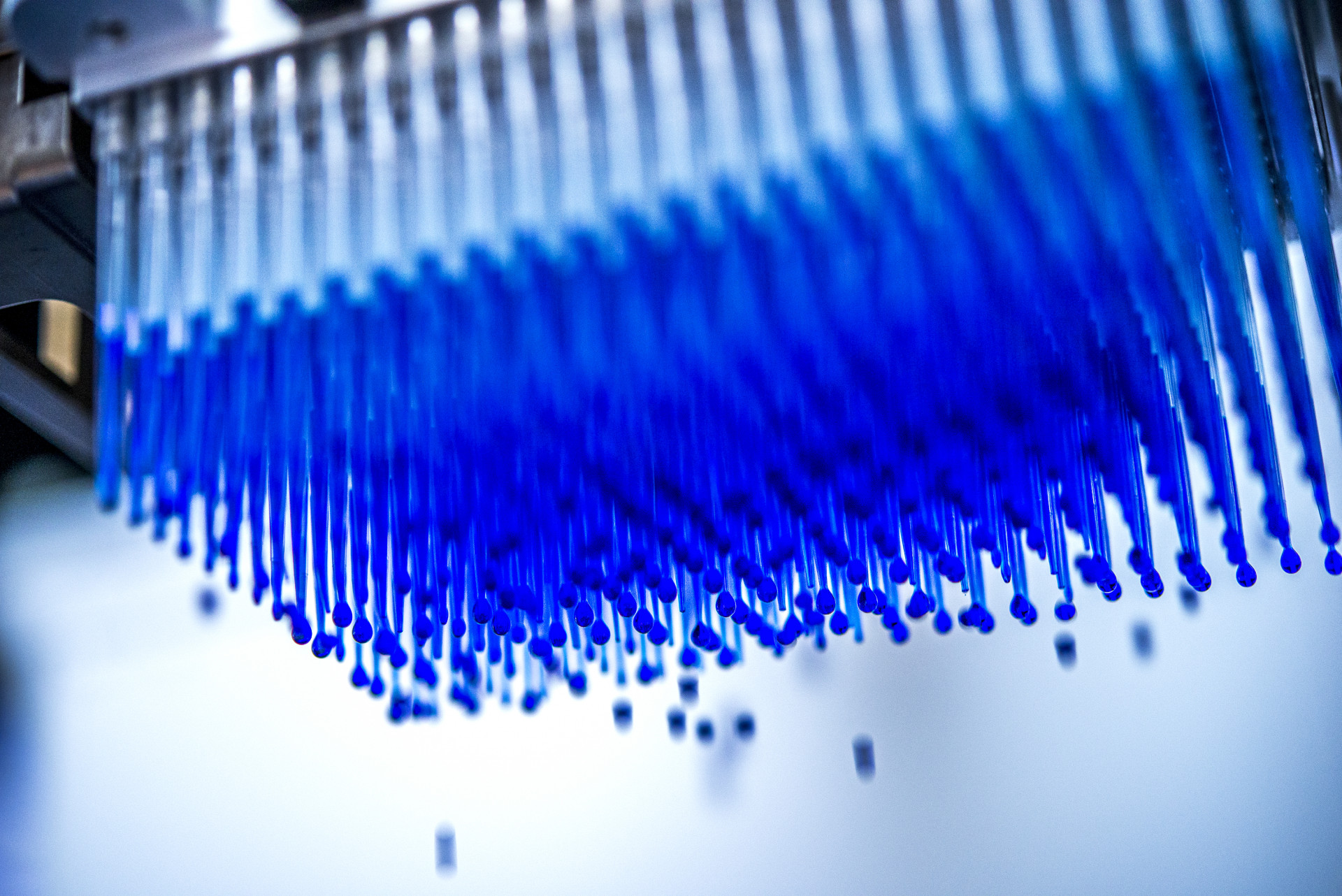

Therefore, the focus of our research activities was to develop new processes for the production of tasty food ingredients from lupine seeds. The processes enable us to completely disintegrate the cell matrix of lupine seeds, whereby unwanted flavor substances are exposed and are subsequently selectively depleted using environmentally friendly solvents (like supercritical CO2 and water) to produce virtually neutral tasting lupine proteins for a wide range of food applications.

Firstly, undesired taste and aroma compounds present in lupine seeds were identified in order to select appropriate solvents for their depletion. Based on the findings, a process comprising different extraction steps using on supercritical CO2 and water, two environmentally friendly solvents, to reduce odor-active and bitter tasting substances was developed. For implementing the developed process for fractionation of lupine seeds the Prolupin GmbH was founded as spin-off company by Fraunhofer in 2010. In 2011 the company launched a first product comprising lupine proteins, namely the “Lupinesse” ice cream. Since 2013 Prolupin GmbH produces high-quality food ingredients from lupine seeds in Grimmen and currently has 12 employees.

Besides Prolupin GmbH, who has implemented the lupine fractionation process first in pilot scale in 2010 and then in industrial scale in 2013, the German food sector as well as the German agricultural sector can benefit from the present developments. Farmers will benefit by establishing new distribution channels for lupine seeds which can be used for human nutrition. Farmers have cultivated lupines as green manure not having directly contributed to their income, up to now, but is subjected to change when lupine seeds are processed further into valuable food ingredients. The food sector will benefit from the developments as they can incorporate these new and innovative ingredients into vegetarian or vegan products.

Fraunhofer Institut für Verfahrenstechnik und Verpackung IVV, Freising:

At present, the Fraunhofer Gesellschaft maintains 67 institutes and research units. One of these institutes is Fraunhofer IVV located in Freising. We develop high-quality food products and safe, effective, and convenient packaging systems. Efficient use of raw materials and minimal environmental impact are priorities in all our development work along the value chain. We also transfer our technologies and expertise to applications outside the food and packaging industries.

Prolupin GmbH:

Prolupin GmbH was founded as spin-off company by Fraunhofer in 2010 and currently has 12 employees. In 2011 Prolupin launched the Lupinesse ice cream which is based on lupne protein isolates. Prolupin GmbH produces high-quality food ingredients from lupine seeds in Grimmen since 2013 with an annual production capacity of 145 t.

The right to nominate outstanding achievements for the Deutscher Zukunftspreis is incumbent upon leading German institutions in science and industry as well as foundations.

The project “Food Ingredients from Lupines Contributing to a balanced diet and enhanced protein supply” was nominated by Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V..

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache