Nominee 2007

Flexibler Keramikseparator

An answer has been provided by Andreas Gutsch, Gerhard Hörpel, and Paul Roth with their invention of a new type of separating layer. Andreas Gutsch, who managed the Creavis Technologies and Innovation division at Evonik Industries AG, is assigned by Evonik as designated Managing Director and responsible for the development of series production at Li-Tec Battery GmbH & CO KG in Kamenz near Dresden. Gerhard Hörpel is responsible for International Relations Management/Marketing at the company’s Marl offices. Paul Roth is a professor emeritus at the Chair for Combustion and Gasdynamics at the University of Duisburg-Essen.

Compact and versatile energy provider

The core of the innovation by the three nominated researchers is a separator for lithium-ion batteries. These rechargeable batteries are used in portable electronic devices such as mobile phones, notebooks, and digital cameras. They are also used to provide electric power in many battery-powered DIY power tools.

more details

Resumes

Dr.-Ing. Andreas Gutsch

- 28.07.1964

- geboren in Neuwied/Rhein

- 1984

- Abitur

- 1984 – 1989

- Studium des Chemieingenieurwesens, Universität Karlsruhe (TH)

Diplom, Thema: „Abscheidung von Rußpartikeln aus der Dieselmotoren Abgasen“ - 1989 – 1990

- Zivildienst, Rettungssanitäter beim DRK in Linz/Rhein

- 1990 – 1995

- Wissenschaftlicher Mitarbeiter am Institut für Mechanische Verfahrenstechnik und Mechanik der Universität Karlsruhe (TH)

- 1993 – 1994

- Mehrere Forschungsaufenthalte Department of Chemical Engineering,

University of Cincinnati, Cincinnati, USA - 1995

- Promotion an der Universität Karlsruhe (TH)

Thema: „Agglomeration feinster gasgetragener Partikel unter dem

Einfluss elektrischer Kräfte“ - 1995 – 1998

- Eintritt in die Degussa GmbH, Hanau, Wissenschaftlicher Mitarbeiter im Konzernbereich Verfahrens- und Prozesstechnik, Abteilung Partikeltechnologie

- 1998 – 2000

- Leiter der Abteilung „Product Engineering feinste Partikeln“ im Konzernbereich Verfahrens- und Prozesstechnik,

Degussa GmbH, Hanau - 2000 – 2002

- Leiter der Abteilung „Projekthaus Nanomaterialien“

- 2002 – 2004

- Geschäftsführer Creavis Technologies and Innovation, Degussa GmbH, Marl

- 2005 – 2007

- Leiter Geschäftsbereich Creavis Technologies & Innovation, Degussa AG, Marl

- seit 2005

- Leiter Creavis Technologies and Innovation, Degussa AG/GmbH, Marl

(heute Evonik Industries AG) - seit 2005

- Lehrauftrag der TU Braunschweig

Weitere Tätigkeiten:

- Mitglied der DFG-Kommission „Exzellenzinitiative Deutschland“

- Vorsitzender des Vorstandes der Dechema Fachsektion Nanotechnologie

- Beirat des Elitestudiengangs „Advanced Materials and Processes“,

Universität Erlangen-Nürnberg - Koordinator des Zukunftsforums Nanotechnologie der Dechema

- Gutachter im wissenschaftlichen Beirat des Institutes für Nanotechnologie (INT) am Forschungszentrum Karlsruhe

- Fachgutachter im DFG-Schwerpunktprogramm „Handhabung hochdisperser Pulver“

- Fachgutachter im DFG-Schwerpunktprogramm „Kolloidale magnetische Flüssigkeiten“

- Fachgutachter im DFG-Sonderforschungsbereich „Nanopartikel aus der Gasphase“

- Fachgutachter des BMBF, Schwerpunkthema Nanotechnologie Nachwuchsförderung

- Fachgutachter im Forschungsprogramm des Landes Nordrhein- Westfalen „Modellbildung und Simulation in der Produktionslinie chemischer Produkte“

- Berufenes Mitglied des Lenkungsgremiums des GVC/VDI-Kompetenz-Feldes „Nanotechnologie“

- Berufenes Mitglied im Dechema-Arbeitsausschuss „Chemische Nanotechnologie“

- Mitglied des Vorstandes der PARTEC 2001

- Mitglied im Europäischen Netzwerk „NanoMat“

- Mitglied im American Institute of Chemical Engineering

Ehrungen:

- 2002

- Dechema-Preis der Max-Buchner-Forschungsstiftung

Dr. rer. nat. Gerhard Hörpel

- 27.11.1953

- geboren in Bad Kreuznach

- 1974

- Abitur

- 1974 – 1983

- Studium der Chemie an der Johannes-Gutenberg-Universität, Mainz

Diplom, Thema: „Fixierung von Cyclophosphamid an Trägersysteme und Untersuchung ihrer Hydrolysekinetik“ - 1982

- Forschungsaufenthalt am National Cancer Institute, NIH, Bethesda, USA

- 1983

- Promotion an der Johannes-Gutenberg-Universität, Mainz

Thema: „Micellbildende Blockcopolymere als neue Transportformen für Pharmaka“

- 1984 – 1989

- Laborleiter, Zentrale Forschung, Hüls AG, Marl

- 1989 – 1992

- Betriebsleiter, Leitung der Synthesekautschukanlage, Bunawerke Hüls, Marl

- 1992 – 1995

- Qualitätsmanagement, Verantwortlicher Koordinator, Hüls AG, Marl

- 1995 – 1998

- Forschungsleiter zentrale Forschung und Entwicklung, Servo Delden BV,

Delden, Niederlande - 1998 – 2002

- Projektleiter, Technologieplattform keramischer Membranfolien,

Degussa GmbH, Creavis Technologies & Innovation, Marl - 2003 – 2006

- Leiter Internes Start-up Membranen, Degussa AG,

Creavis Technologies & Innovation, Marl - seit 2006

- International Relations Management/Marketing, Degussa AG/GmbH,

Creavis Technologies & Innovation, Marl (heute Evonik Industries AG)

Weitere Tätigkeiten :

- Mitglied der European Membrane Society

- Mitglied im Dechema-Fachausschuss Membranen

Ehrungen:

- 2003

- Innovationspreis Ruhrgebiet, 2. Platz

- 2004

- Innovation Award der Degussa GmbH

Prof. Dr.-Ing. Paul Roth

- 13.11.1938

- geboren in Duisburg

- 1960

- Studium des allgemeinen Maschinenbaus an der Rheinisch-Westfälischen Technischen Hochschule (RWTH), Aachen

- 1965

- Diplom-Hauptprüfung, RWTH Aachen

- 1971

- Promotion zum Dr.-Ing. an der RWTH Aachen

- 1965 – 1971

- Wissenschaftlicher Mitarbeiter, Institut für Luftstrahlantriebe,

Deutsches Zentrum für Luft- und Raumfahrt (DLR), Köln, - 1971 – 1974

- Abteilungsleiter Institut für Reaktionskinetik, Deutsches Zentrum

für Luft- und Raumfahrt (DLR), Stuttgart

- 1974 – 1984

- Wissenschaftlicher Rat und Professor für Strömungstechnik,

Universität Duisburg-Essen - 1984

- Forschungsaufenthalt an der Stanford University, Stanford, USA

- 1985

- Ruf an die Universität Duisburg-Essen, Lehrstuhl für Verbrennung und Gasdynamik

- 1982 – 1997

- Sprecher des Sonderforschungsbereichs 209 „Stoff- und Energietransport in Aerosolen“

- 1999 – 2002

- Sprecher des Sonderforschungsbereichs 445 „Nano-Partikel aus der Gasphase - Entstehung, Struktur, Eigenschaften“

- 2004

- Emeritierung

Weitere Tätigkeiten:

- 1985 – 1995

- Mitglied der Forschungskommission der Universität Duisburg

- 1985

- Dekan des Fachbereichs Maschinenbau

- 1986 – 2000

- Vorsitzender des Promotionsausschusses des Fachbereichs Maschinenbau

- seit 1988

- Mitglied des Int. Advisory Board of the Shock Wave Symposium

- 1993

- Co-Chairman der European Aerosol Conference

- 1994 – 1998

- Editorial Board der Zeitschrift Int. J. Chem. Kin.

- 1995

- Paul-Vieille-Memorial Lecture, Caltech, Pasadena, USA

- 1997 – 1999

- Editorial Board der Zeitschrift J. Aerosol Science

- seit 1998

- Vorstandsmitglied der Deutschen Sektion des Combustion Institute

Editorial Board der Zeitschrift Shock Wave Journal

Board of Directors, Int. Symposion on Reactive Systems - seit 2000

- Deputy Editor der Zeitschrift Combustion and Flame

- 2001 – 2003

- Prodekan der Fakultät für Ingenieurwissenschaften

- seit 1978

- Gutachter für die DFG in vielen Sonderforschungsbereichen,

Gutachter für NSF, DOE - seit 2001

- Vertrauensdozent der DFG

Ehrungen:

- 1971

- Borchers-Medaille der Rheinisch-Westfälischen Technischen Hochschule, Aachen

- 1973

- Otto-Mader-Preis des Deutschen Zentrums für Luft- und Raumfahrt

- 1992

- Silbermedaille des International Combustion Institute

- 2003

- Numar-Manson-Goldmedaille für Forschungsleistungen auf dem Gebiet der Verbrennung, Gasdynamik und Partikeltechnik

Contact

Spokesperson

Dr.-Ing. Andreas Gutsch

Bereichsleiter

Evonik Industries AG

Creavis Technologies & Innovation

Paul-Baumann-Str. 1

45764 Marl

Tel.: +49 (0) 2365 / 49 94 84

Fax: +49 (0) 2365 / 49 80 94 84

E-Mail: a.gutsch@li-tec.de

Web: www.evonik.com

Press

Alexandra H. Boy

Konzernpresse

Evonik Industries AG

Rellinghauser Str. 1 - 11

45128 Essen

Tel.: +49 (0) 201 / 17 73 167

Fax: +49 (0) 201 / 17 73 030

Mobil: +49 (0) 151 / 12 02 80 39

E-Mail: alexandra.boy@evonik.com

Web: www.evonik.com

Beate H. Kostka M.A.

Leiterin der Presse- und Informationsstelle

Universität Duisburg-Essen Campus Duisburg

Lotharstr. 65

47057 Duisburg

Tel.: +49 (0) 203 / 37 92 430

Fax: +49 (0) 203 / 37 92 428

E-Mail: beate.kostka@uni-due.de

Web: www.uni-due.de

A description provided by the institutes and companies regarding their nominated projects

Small lithium-ion batteries are already found today in virtually every notebook, cell phone, and camcorder in use worldwide. The state-of-the-art energy packages have recently also found application in powerful power tools. However, lithium-ion batteries have not been able to date to be used in cars or even larger stationary applications. The reason being that safety was not sufficiently guaranteed at the battery and cell level. And, it is this that is so important in large-volume batteries.

Evonik Industries AG has now succeeded in making the lithium-ion battery clearly safer, more powerful, and durable with their SEPARION® separators, the trendsetting production from the group’s own portfolio of lithium-ion technology, and thus opened up extremely attractive applications for portable and stationary large batteries to this technology – a sector for which two figure growth rates are predicted.

Because of its importance to the society as a whole, two examples are to be emphasized from among the possible applications. On the one hand, this energy carrier can also be used for the first time as a large-scale battery in hybrid vehicles. The advantages afforded by the combined drive system consisting of internal combustion engine and electric motor can be exploited even better: up to 50 percent less fuel consumption, correspondingly fewer emissions, and better acceleration. On the other hand, large-scale electrical energy storage can make a major contribution to the use of regenerative energy sources: in particular by temporary storage of power in mains-independent solar installations and by balancing the mains supply by stabilizing the electricity grid or load leveling in mains-locked wind power and solar installations. In this way, conventional power plant capacity can be utilized much better in the future. Both applications demonstrate the relevance of storing electrical energy has in the achieving of the targets stipulated by the Kyoto protocol. Mobile applications in cars cut fuel consumption in half with correspondingly lower CO2 emissions. Stationary storage of electrical power makes produced regenerative energy available again with efficiencies of over 95 percent – a figure no other technology even comes close to reaching.

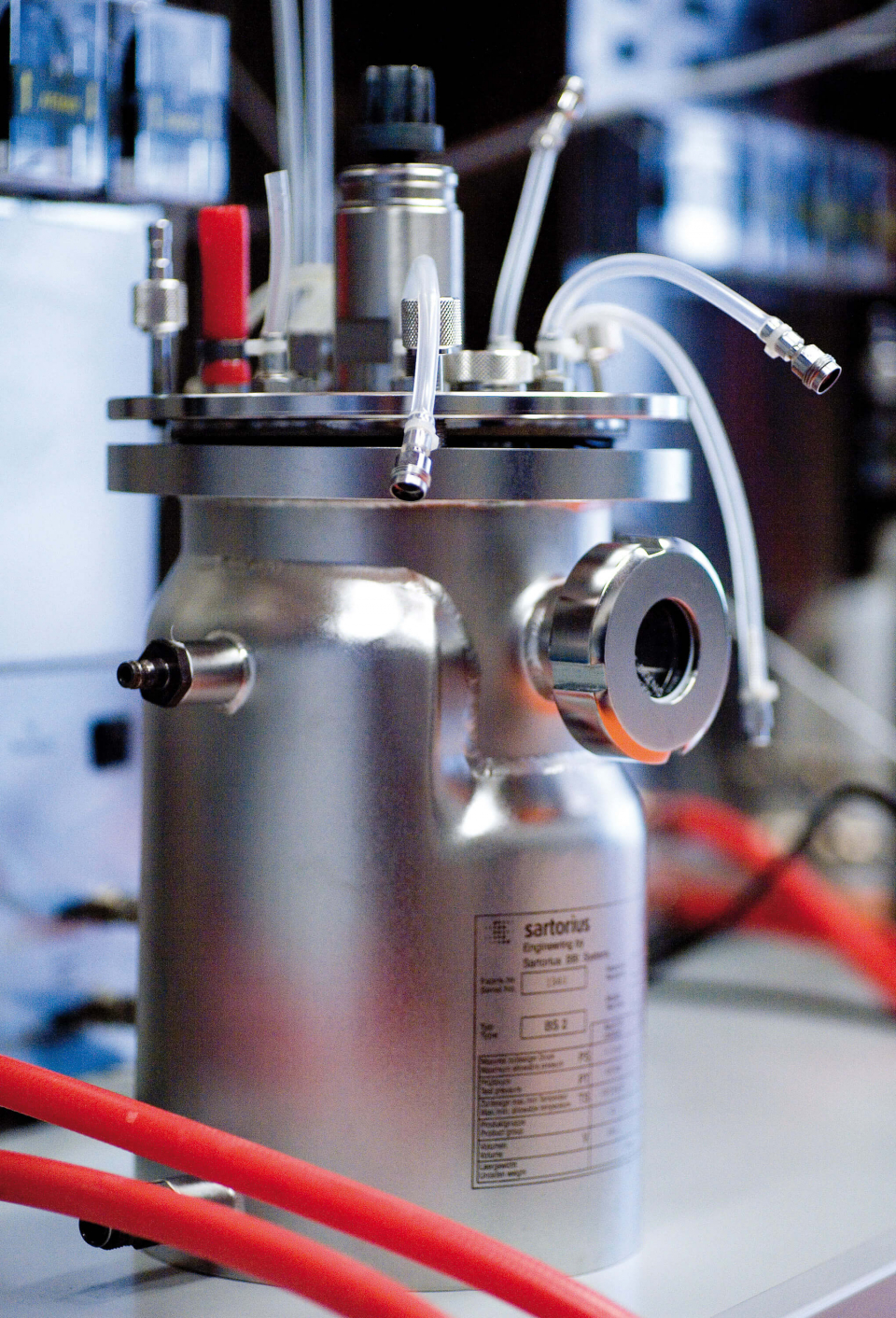

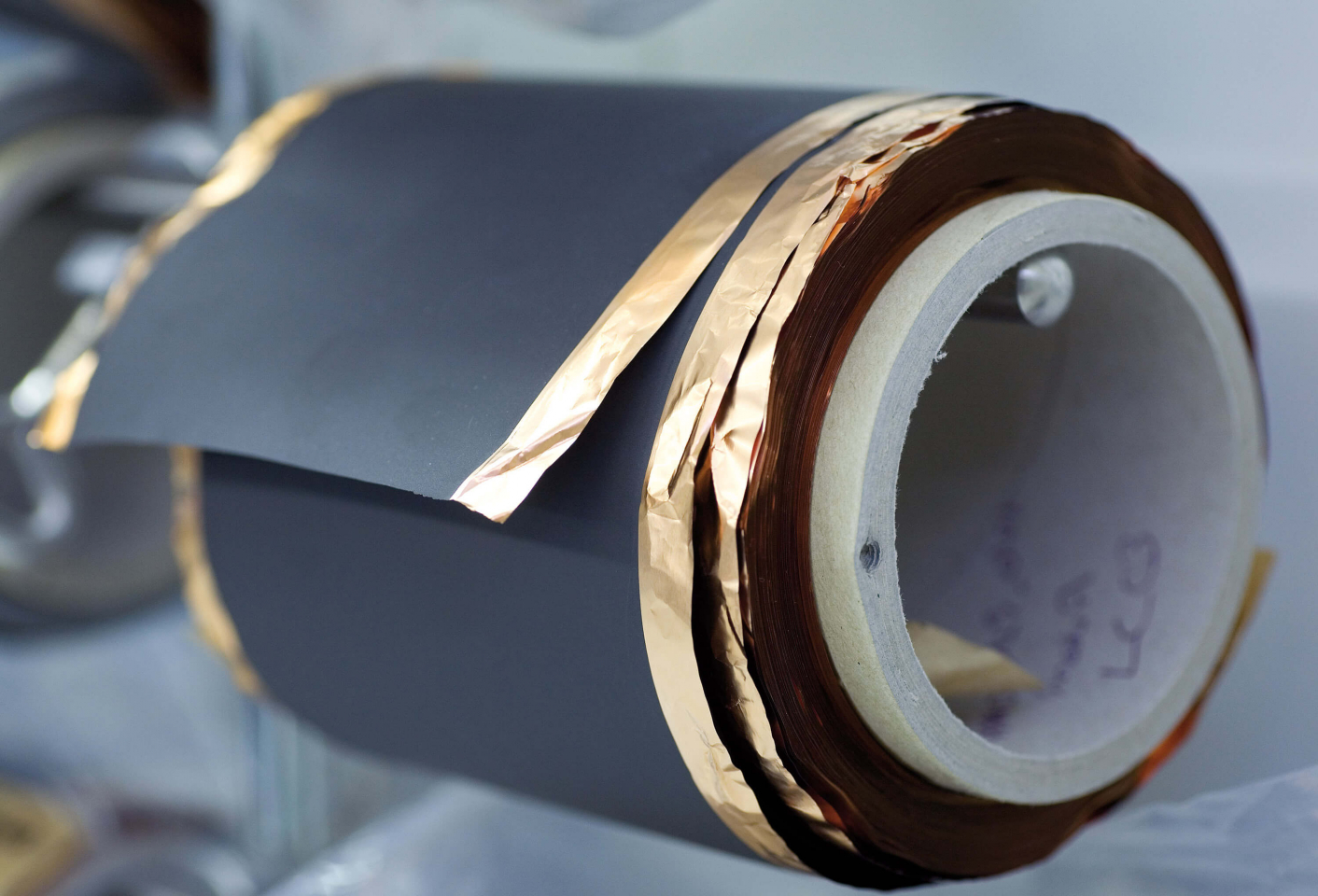

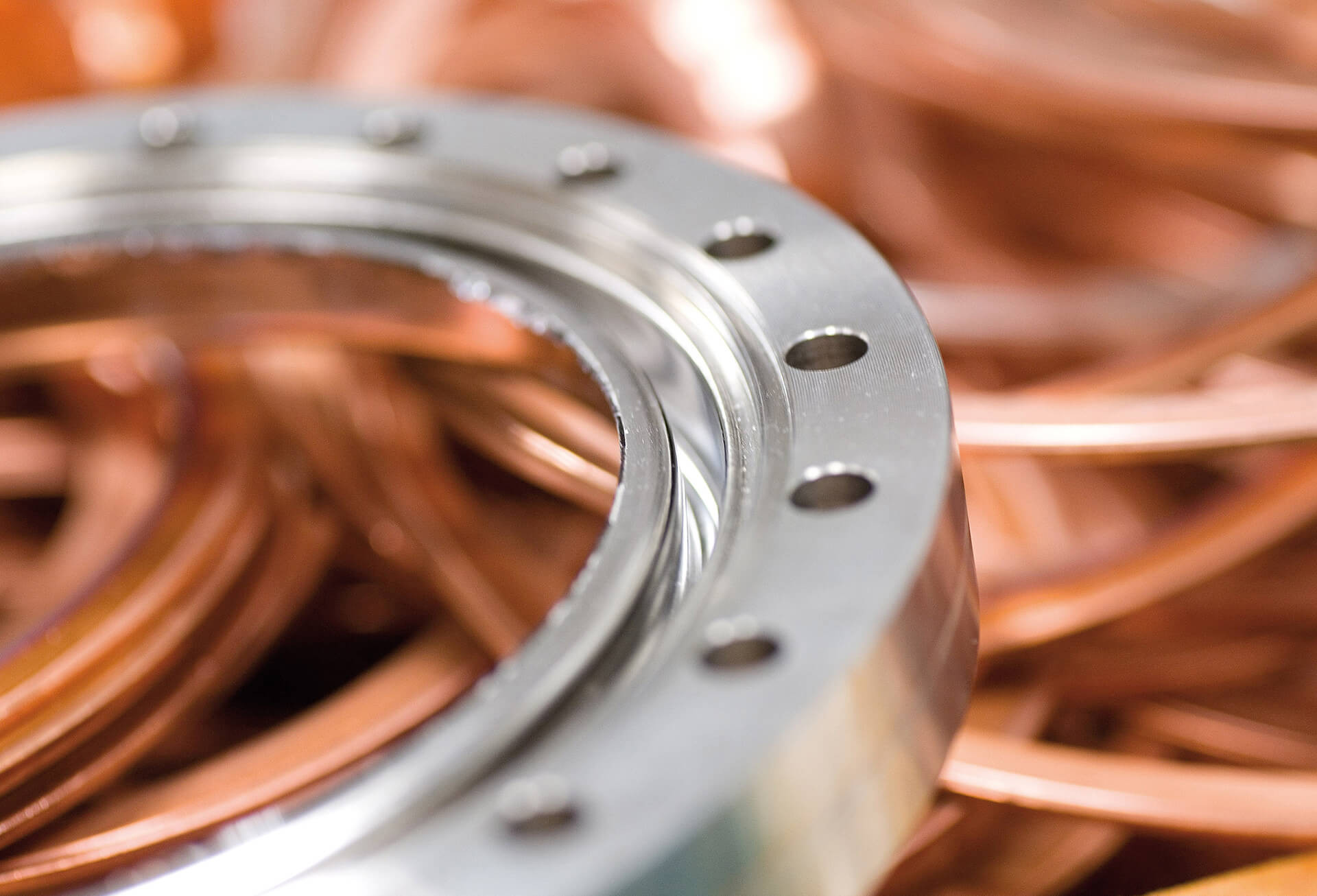

The fail-safe use of the large-format lithium batteries is made possible by SEPARION, a newly developed ceramic battery separator from Evonik Industries. SEPARION returns to a fundamental development in the area of nanomaterials concluded in a trendsetting cooperation between Evonik, the German Research Foundation (DFG, Deutschen Forschungsgemeinschaft), and seven universities.

The innovation targets a billion Euro market. According to forecasts, the market for lithium-ion battery materials will climb from its current figure of 1.4 billion Euros to around 3.9 billion Euros by 2015, if the market segments “Hybrid Vehicles” and “Stationary Current Storage Systems” are tapped. SEPARION is the key to these segments.

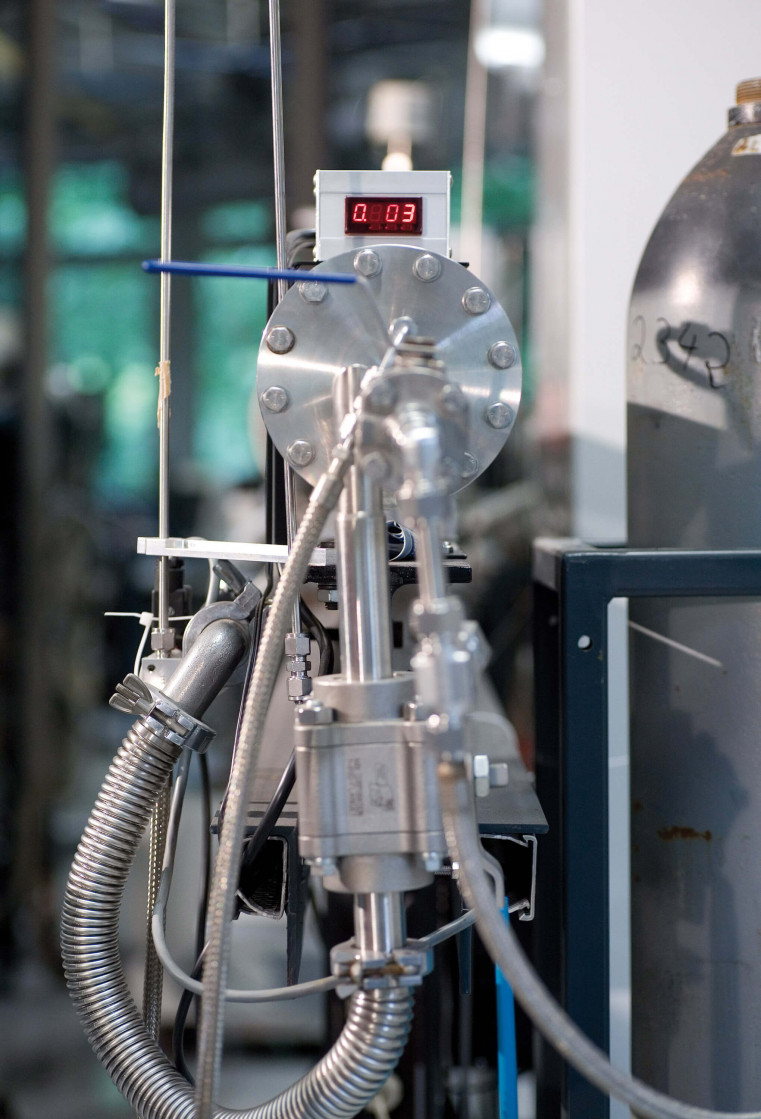

Because of the high innovation potential and economic importance, Evonik Industries has already invested 50 million Euros in the development and marketing of the new ceramic composite materials as well as in the construction of pilot and production facilities. 100 new jobs have been created through the development work and investments in conjunction with the development, production, and marketing of the components for the lithium-ion technology and adjoining technologies. If the level of growth even comes close to predictions, there will be a tenfold increase in the number of jobs.

Moreover, the revolutionary development described has a realistic chance of bringing back part of the battery know-how from Asia, of strengthening the German automotive industry, and thereby allowing Germany to participate in the burgeoning attractive market.

Evonik Industries AG – the Creative Industrial Group from Germany

Evonik Industries is the creative industrial group from Germany with the high-earning and promising business areas of Chemicals, Energy, and Real Estate. Evonik is the world’s leader in special chemicals, experts for power generation from hard coal and renewable energies, as well as one of the largest private residential property holders in Germany.

Evonik Industries is active in more than 100 countries around the world. With more than 43,000 employees, company turnover in 2006 was around 14.8 billion Euros with an operative result (EBIT) of over 1.2 billion Euros. Current plans are to enter the capital market in the 1st half of 2008.

The inter-group research unit Creavis Technologies and Innovation is active within Evonik Industries. Its mission is rapid entry into new, profitable, and trendsetting business in markets with strong growth potential. Activities focus on the need areas communications and information, personal mobility, new resources, energy storage, as well as conservation of resources and sustainable development. The innovation process ranges from identifying promising technologies and attractive business options with potential to the technological implementation of ideas that promise success and to the market launch of newly developed products and technologies by internal start-ups. In project houses and science-to-business centers, Creavis develops innovative technology platforms and products for new business. This is where Dr. Andreas Gutsch and Dr. Gerhard Hörpel decisively advanced the development of SEPARION over the past few years.

Science to Business Center Nanotronics

The group’s own Science to Business Center Nanotronics was started in April 2005 and develops innovative system solutions on the basis of nanomaterials for the electronics industry. Areas of application include printable electronics, affordable displays, and portable energy systems as well as flexible, thin-film solar cells for more efficient utilization of solar energy. With “Science to Business Nanotronics” Evonik Industries has taken a new approach to the integration of science and business. 80 scientists from Evonik together with university research and development teams, suppliers, and customers are advancing cross-industry and inter-disciplinary developments. Creavis has also concluded more than 35 joint ventures with universities research institutes like the Fraunhofer Association. One example is the cooperation on the research initiative “Function Materials and Material Analysis of Lithium High-Power Batteries” with the Deutsche Forschungsgemeinschaft (DFG) and twelve German universities. The Nanotronics projects are jointly financed by the German Land North Rhine-Westphalia and the European Union.

Duisburg University: Institute for Combustion and Gasdynamics

The Institute for Combustion and Gasdynamics is one of the largest and most research-oriented institutions in the faculty for engineering at the University of Duisburg-Essen. It was established with the offering of the chair at Duisburg to Professor Roth in 1985 and traditionally studies particle generation and characterization, aerosol measuring technologies, chemical kinetics, and laser-optical in-situ diagnostics in reactive flow systems. In 2004, Prof. Dr. Christof Schulz assumed the chair and has kept the aforementioned research focus.

The chair with its 35 employees is involved in numerous national and international joint research projects. Through the synthesis of nanoparticulate materials, it plays a leading role in the special research division “Nanoparticles from the gas phase” established by Professor Roth and contributes considerably to the research focus “Nanoresearch” of the University of Duisburg-Essen which is combined in the Center for Nanointegration Duisburg-Essen, CeNIDE.

The chair is also active in “Nanotronics” postgraduate studies and contributes to the newly established Bachelor’s and Master’s course “Nanoengineering”.

The right to nominate candidates for the German Future Prize (Deutscher Zukunftspreis) is granted to leading German institutes in science and industry, as well as foundations.

The project “Nanolayer with Megapower – Flexible Ceramic Separator creates Breakthrough in Large Lithium-Ion Energy Stores” was nominated by the Deutsche Forschungsgemeinschaft.

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache