Nominee 2004

UV-Werkstoffmodifikation

Horst Joachim Lindner, Hans Wilhelm Bergmann and Robert Queitsch have proven it can be done by using an UV laser to modify the material used in cylinder liners. Horst Lindner is a research associate for product and manufacturing methods at AUDI AG in Ingolstadt; Hans Wilhelm Bergmann holds a Chair for Materials Science at the University of Erlangen; Robert Queitsch is a research associate at ATZ Entwicklungszentrum in Sulzbach-Rosenberg.

Immense influence of the cylinder surface

Combustion engines produce drive by converting the chemical energy of fuel into mechanical power. How high power and consumption are largely depends on the structure of the cylinder surface. It serves as a slideway for piston rings and pistons and simultaneously seals the combustion chamber at the interface to the engine crankcase.

more details

A description provided by the institutes and companies regarding their nominated projects

Dipl.-Ing. Horst Joachim Lindner

- 17.04.1942

- geboren in Lübeck

- 1964 – 1969

- Studium des Maschinenbaus und der Produktionstechnik an der Technischen Universität Berlin

- 1970 – 1974

- Gruppenleiter Produkt-/Fertigungsverfahrenstechnik OSRAM GmbH, Werk Augsburg

- 1971 – 1972

- Lehrtätigkeit auf dem Gebiet der Technischen Mechanik, Private Techniker Schule, Augsburg

- 1974 – 1979

- Gruppenleiter Produkt-/Fertigungsverfahrenstechnik, MAN-Neue Technologie, München

- 1975 – 1978

- Lehrtätigkeit auf dem Gebiet Maschinenelemente und Konstruktionslehre, Fachhochschule München

- Seit 1979

- Fachreferent Produkt-/Fertigungsverfahrenstechnik, AUDI AG, Ingolstadt

- 1982 – 1997

- Mitglied des Beirates des Ortsverbandes Verein Deutscher Ingenieure (VDI), Ingolstadt

Prof. Dr.-Ing. habil. Hans Wilhelm Bergmann

- 22.05.1950

- geboren in Wuppertal

- 1968 – 1972

- Studium der Mathematik und Physik an der TU Clausthal

- 1973 – 1977

- Wissenschaftlicher Mitarbeiter, später wissenschaftlicher Assistent am Institut für Metallkunde und Metallphysik, TU Clausthal

- 1977

- Promotion

- 1978 – 1985

- Wissenschaftlicher Assistent, später C1-Professor am Lehrstuhl für Werkstoffkunde und Werkstofftechnik der TU Clausthal

- 1985

- Habilitation im Fach Werkstoffkunde und Werkstofftechnik

- seit 1986

- C3-Professor am Lehrstuhl Werkstoffwissenschaften 2, Universität Erlangen; Leiter des Bereichs Werkstofftechnik am Bayerischen Laserzentrum; Mitglied des Wissenschaftlichen Arbeitskreises Lasertechnik

- seit 1989

- Vorstand des Bereichs Kurzpulslasertechnik und Hochleistungswerkstoffe am Applikations- und Technikzentrum für Energieverfahrens-, Umwelt- und Strömungstechnik (ATZ-EVUS)

- 1990 – 1991

- Kommissarischer Leiter des Lehrstuhles Werkstoffwissenschaften 2, Metalle, Universität Erlangen

- 1997 – 2000

- C4-Professor am Lehrstuhl Metallische Werkstoffe, Universität Bayreuth

Dipl.-Phys. Robert Queitsch

- 21.09.1963

- geboren in Nürnberg

- 1986 – 1993

- Studium der Physik an der Friedrich-Alexander-Universität Erlangen-Nürnberg

- seit 1989

- Mitglied in der Naturhistorischen Gesellschaft Nürnberg e.V.

- 1992

- Wissenschaftliche Hilfskraft am Applikations- und Technikzentrum für Energieverfahrens-, Umwelt- und Strömungstechnik (ATZ-EVUS), Lasergruppe um Prof. Dr. Hans Wilhelm Bergmann, Vilseck

- seit 1993

- Wissenschaftlicher Mitarbeiter am ATZ Entwicklungszentrum; Dort Bearbeitung von Forschungsprojekten mit Schwerpunkt in der Lasertechnik, Vilseck, Sulzbach-Rosenberg und Amberg

- 1992 – 2002

- Mitglied in der Deutschen Physikalischen Gesellschaft (DPG)

Contact

Spokesperson

Dipl.-Ing. Horst Joachim Lindner

AUDI AG

Abt. Planung Motor/Fahrwerk (I/PA-1)

85045 Ingolstadt

Tel.: +49 (0) 841 / 89 34 384

Fax: +49 (0) 841 / 89 32 898

E-Mail: horst.lindner@audi.de

Press

Eric Felber

Kommunikation Unternehmen und Wirtschaft

AUDI AG

I/GP-U1

85045 Ingolstadt

Tel.: +49 (0) 841 / 89 90 703

Fax: +49 (0) 841 / 89 92 370

E-Mail: eric.felber@audi.de

Dr. Wolfgang Weber

Fachhochschule Amberg-Weiden

Hochschule für Technik und Wirtschaft

Kaiser-Wilhelm-Ring 23

92224 Amberg

Tel.: +49 (0) 9621 / 48 21 97

Fax: +49 (0) 9621 / 48 21 10

E-Mail: w.weber@fh-amberg-weiden.de

A description provided by the institutes and companies regarding their nominated projects

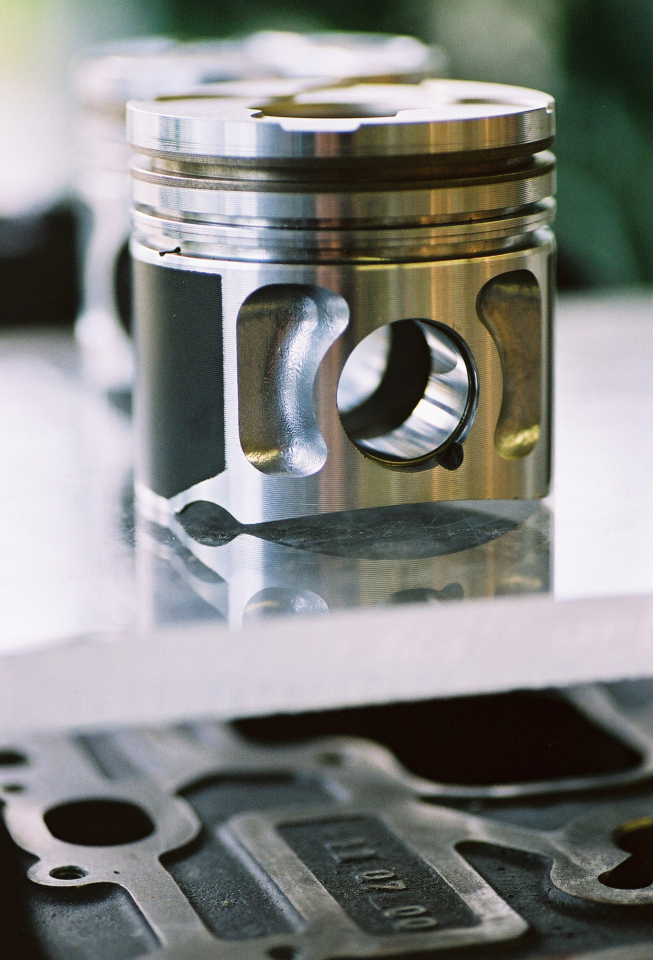

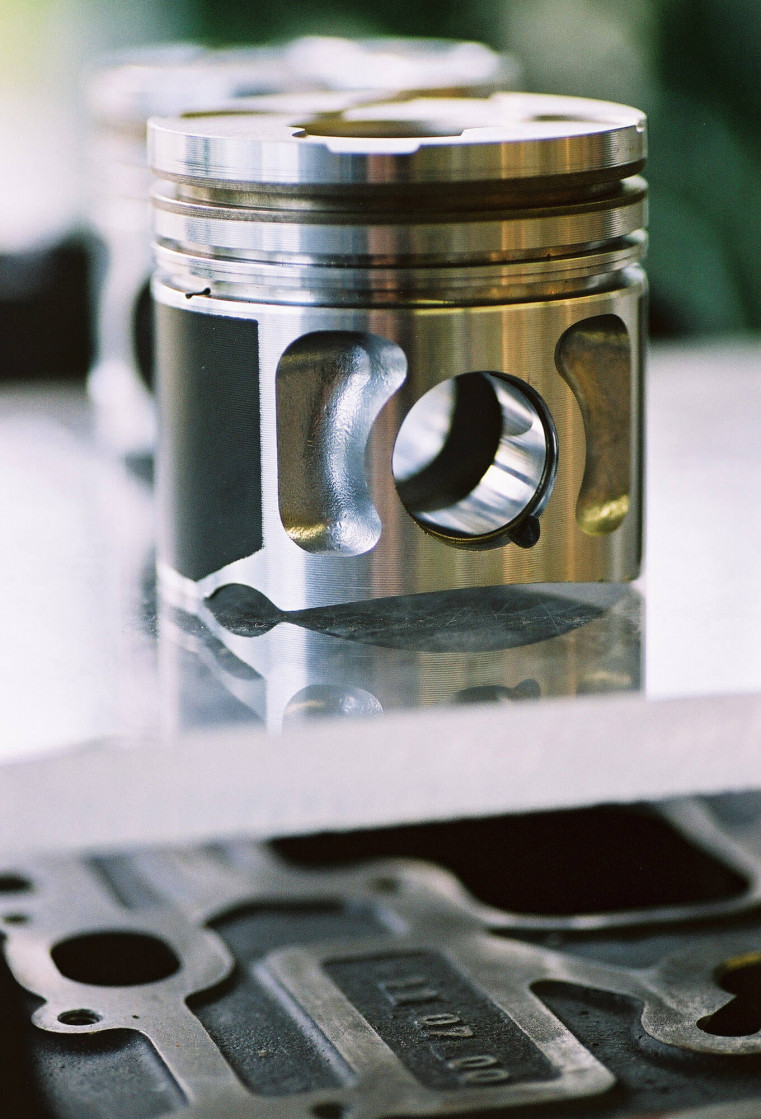

Cylinders are the heart of an engine. They contribute the mechanical energy to drive a vehicle – but in the process they use plenty of oil and produce noxious emissions.

Can these disadvantages be avoided?

Horst Joachim Lindner, Hans Wilhelm Bergmann and Robert Queitsch have proven it can be done by using an UV laser to modify the material used in cylinder liners. Horst Lindner is a research associate for product and manufacturing methods at AUDI AG in Ingolstadt; Hans Wilhelm Bergmann holds a Chair for Materials Science at the University of Erlangen; Robert Queitsch is a research associate at ATZ Entwicklungszentrum in Sulzbach-Rosenberg.

Immense influence of the cylinder surface

Combustion engines produce drive by converting the chemical energy of fuel into mechanical power. How high power and consumption are largely depends on the structure of the cylinder surface. It serves as a slideway for piston rings and pistons and simultaneously seals the combustion chamber at the interface to the engine crankcase.

An important goal of development for car manufacture is to reduce fuel consumption. This is achieved by higher combustion pressures in the piston. Associated with this, however, are higher mechanical stresses on the cylinder liners and piston rings. In the past, the cylinder liner surfaces were treated by honing, a specific bore technology, to apply a special structure for oil retention. Consequently, however, a lot of oil is used. The result: vast amounts of unburned hydrocarbons are released with the exhaust. Moreover, the honing process also increases wear.

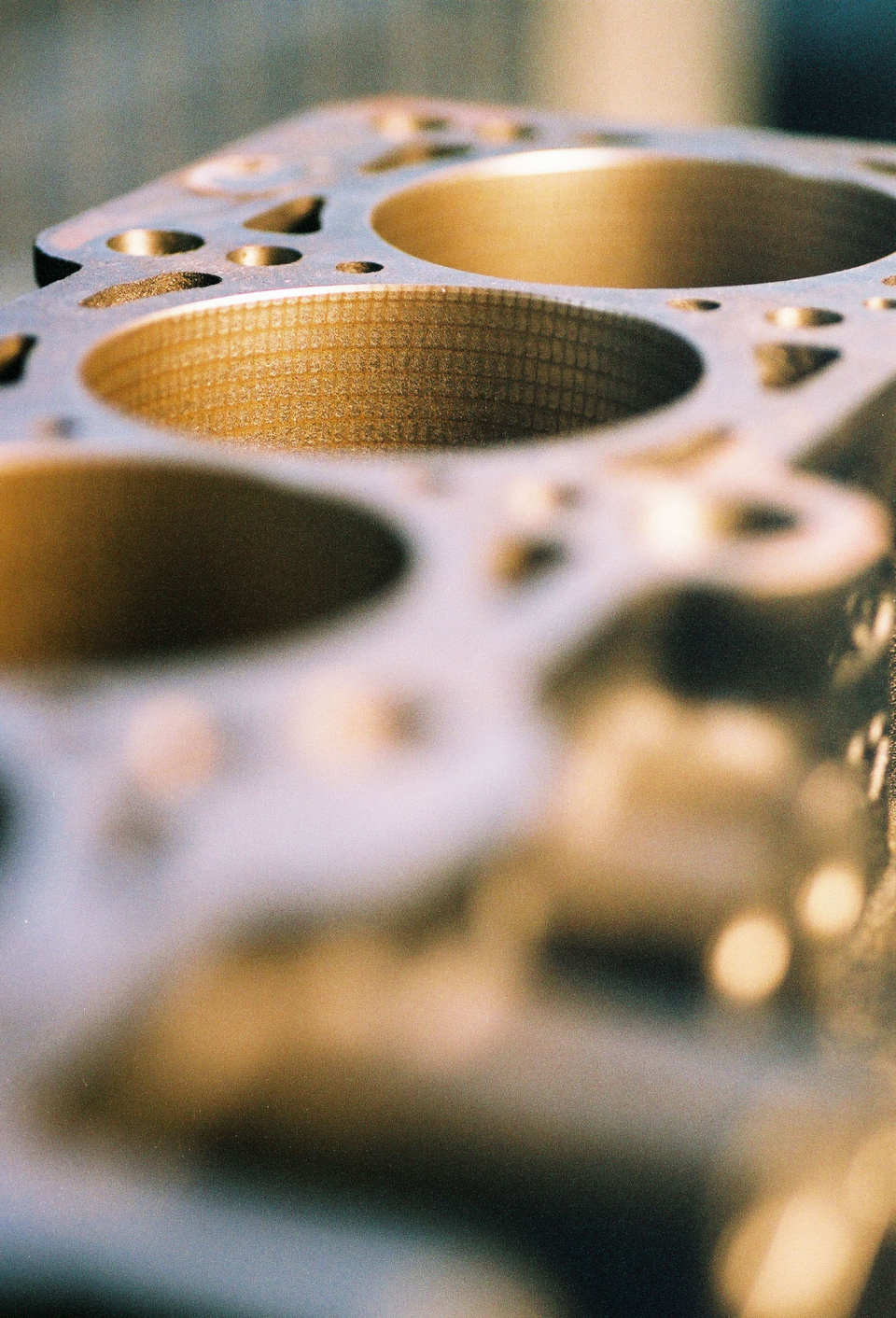

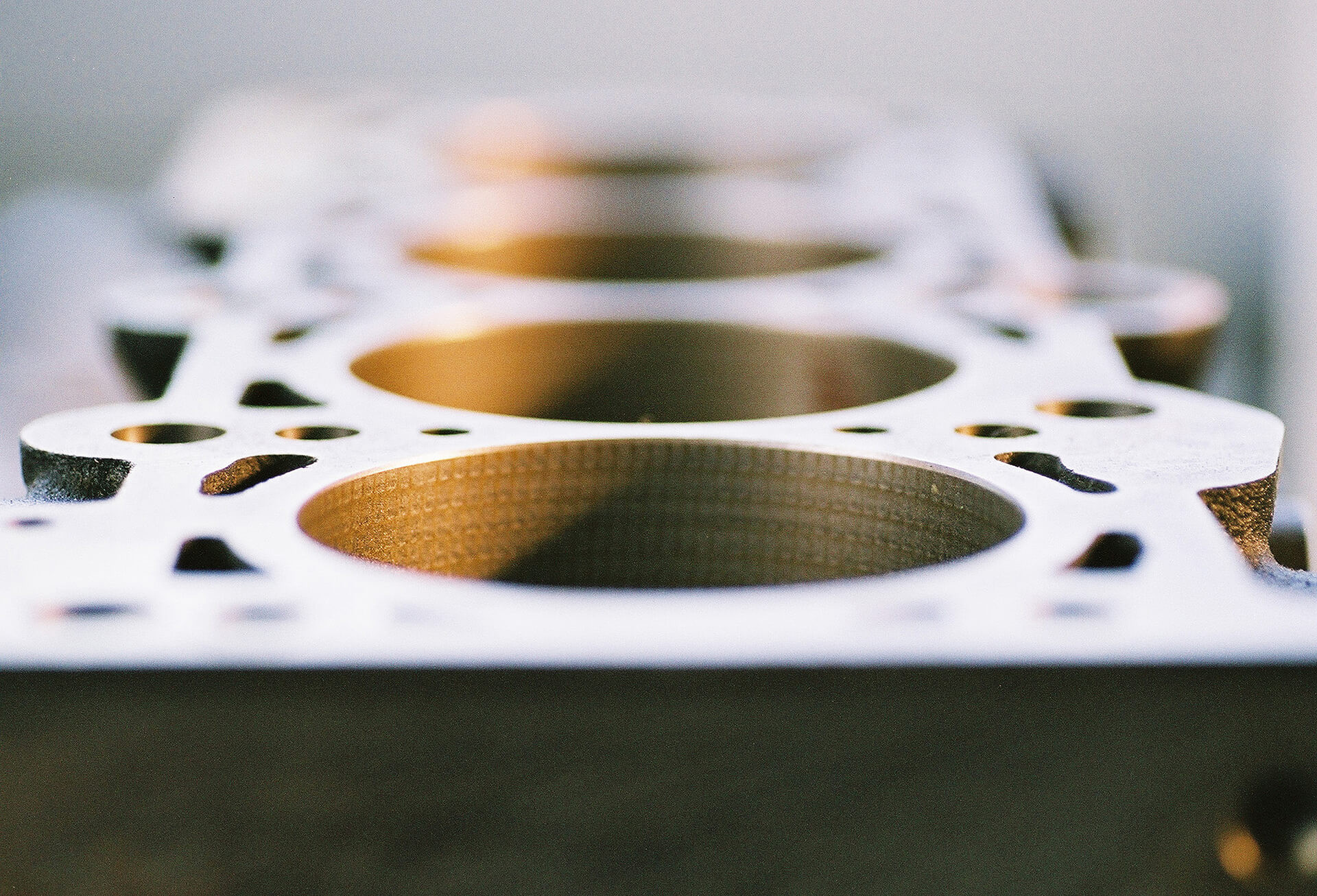

Laser pulses provide robustness

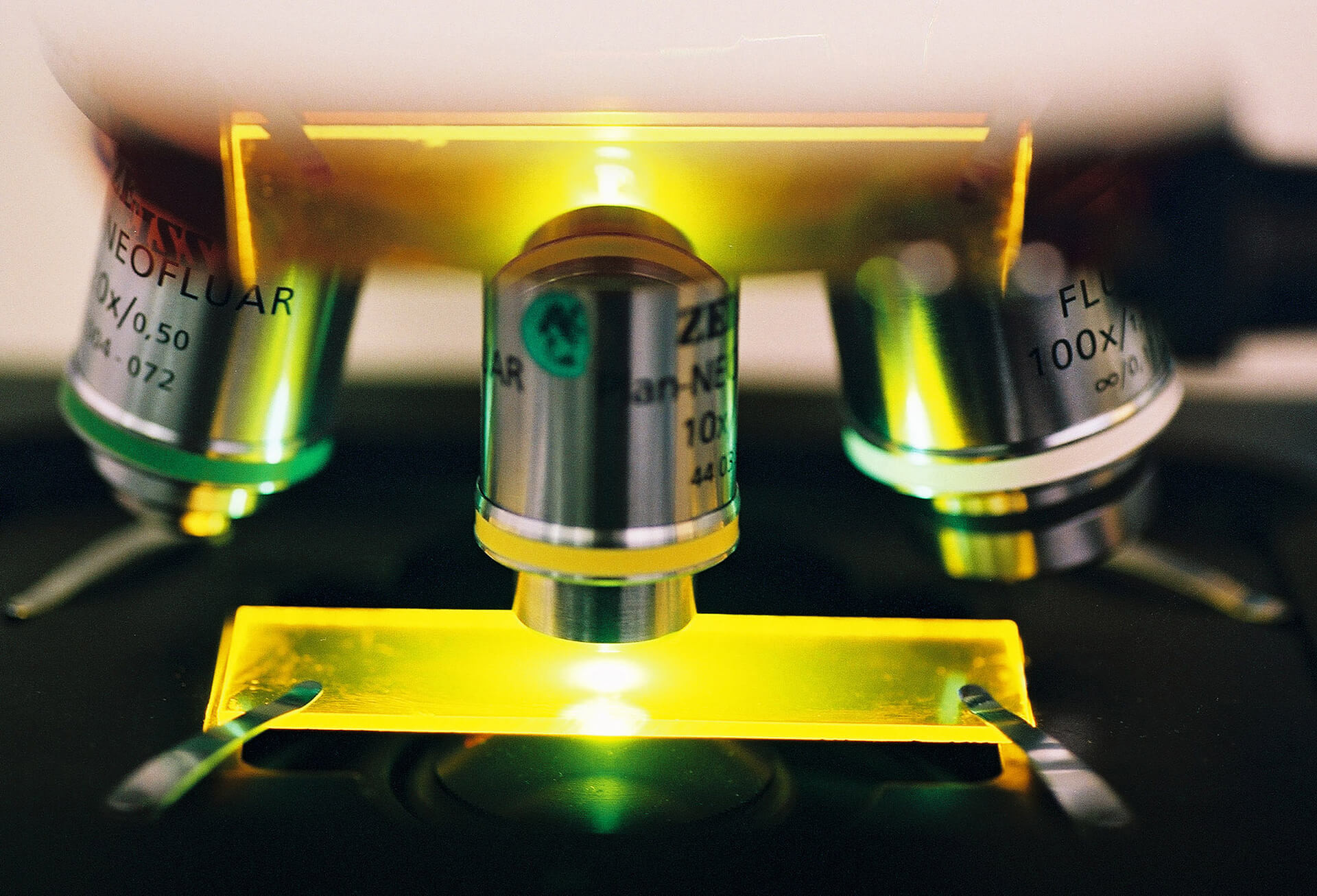

The team’s innovation is based on the large-area treatment of cast iron cylinder liners with an ultraviolet (UV) laser in the path of the piston rings. The laser pulses vaporize material on the cylinder walls. Graphite separations in the cast iron form a special surface structure. At the same time, the liner surface is melted, creating a plasma. Nitrogen is introduced to the molten layer which hardens in a nanocrystalline microstructure. This treatment makes the cylinder liner much more durable as it continues during use to turn into a fine structure with superplastic properties. The result: engine wear decreases. Oil consumption – and thus the emissions harmful to the environment – is considerably reduced.

The UV laser technology is now an integral part of series production of diesel engines at AUDI AG. It can also be applied for other machine parts made of cast iron or steel materials which are subjected to high mechanical stresses.

The right to nominate outstanding achievements for the German Future Award is incumbent on leading German institutions in Science and Industry as well as foundations.

The project “Lower frictional wear and oil-consumption in IC engines by modifying the materials used in cylinder liners with UV laser exposure” was nominated by the Stiftung Werner-von-Siemens-Ring.

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache