Nominee 2023

Open to all

Dr. Stephan Biber, Dr. David Grodzski and Prof. Michael Uder have found a solution. The three nominees have developed a new platform for magnetic resonance imaging which represents a radical departure from the paradigm “ever larger, ever more powerful” exemplary of the previous technological progress in this field. The team is the first to succeed in producing high-resolution and diagnostically accurate images of the internal body using MRI and even comparably weaker magnetic fields – thereby reducing considerably both the technical complexity as well as the cost of the equipment.

The principle behind magnetic resonance tomography is based on the magnetic properties of the atomic nuclei of hydrogen – a chemical element found everywhere within the body in varying concentrations. Using a magnetic field, the otherwise randomly oriented spins of the nuclei can be arranged almost fully parallel much like the needles of a compass. They are then diverted from this direction by a pulsed radio wave. The MRI system measures the reaction of hydrogen nuclei.

By applying magnetic field gradients, the reactions can be differentiated accurately in different parts of the body. The resulting images provide doctors with information that would not otherwise be available. Rheumatic joint inflammation, for example, can be detected long before any bone destruction would be visible on an x-ray. After a heart attack, it can be reliably determined where heart muscle can be saved by vascular surgery. In the case of liver tumors, it is possible to precisely identify healthy tissue that can be spared during surgery without jeopardizing the operation’s overall success.

The spatial resolution of the images increases with the magnetic field strength. Consequently, development of the new generations of MRI scanners over the past few decades tended to increasingly stronger fields. This resulted on the one hand in enormous progress in the diagnosis and treatment of many and even rare diseases. On the other hand, the machines consequently became ever more technically complex, larger and heavier – as well as more expensive. The result: in many places the use of state-of-the-art, high-resolution magnetic resonance imaging had not been possible – for example in countries with limited financial means. The demands placed on the infrastructure also cannot be solved everywhere and are not just a problem faced in newly industrialized countries.

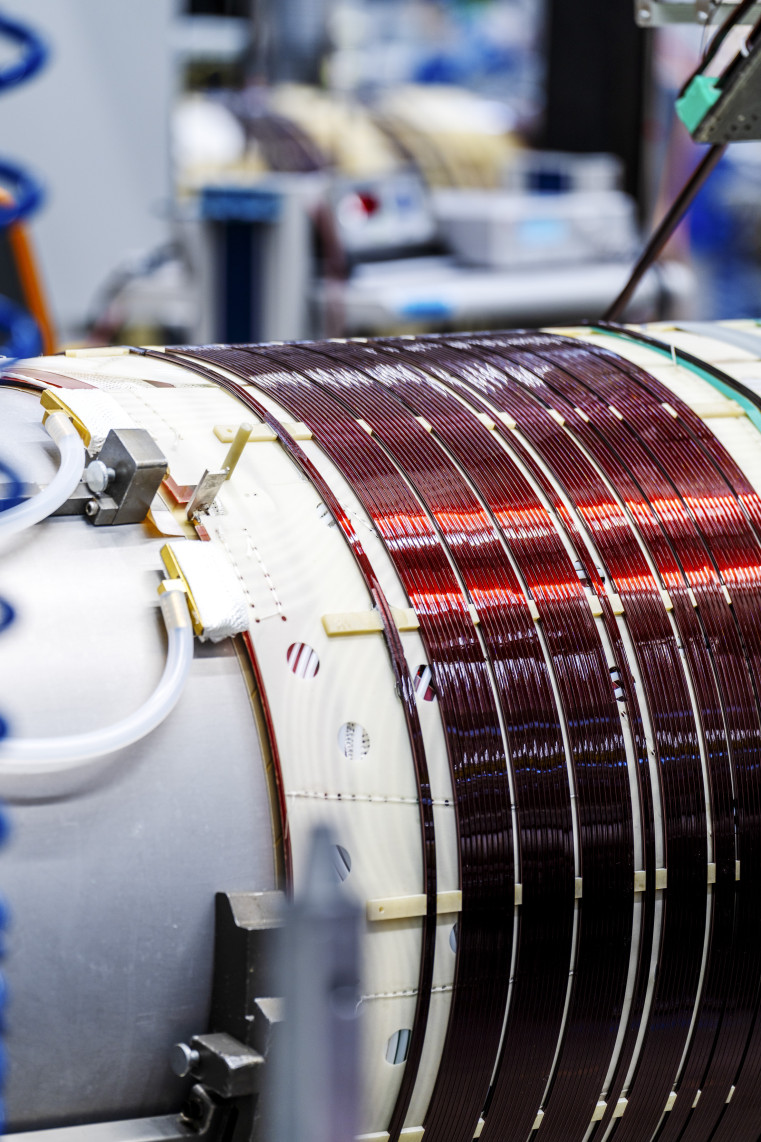

The magnetic field coils, for example, need large amounts of liquid helium to cool the powerful magnetic field coils – and the production of liquid helium is time-consuming and costly. In addition, other factors are the machine weight of several tons and its size. These aspects are obstacles that both make installation of these machines difficult or rule it out entirely it in many buildings for structural reasons. Another aspect is that specialized personnel is needed to operate the machines – who are ever more difficult to find worldwide owing to a shortage of qualified and trained staff.

More Details

Resume

Dr.-Ing. Stephan Biber

- April 11,1976

- Born in Eichstaett, Germany

- 1986 – 1995

- Willibald-Gymnasium Eichstaett, Germany, Qualification: High-school Diploma

- 1996 – 1999

- Friedrich-Alexander-University Erlangen-Nuremberg, Erlangen, Germany, Graduate Program in Electrical Engineering

- 1999 – 2000

- University of Colorado Boulder, Boulder, Colorado, USA, Master of Science in Electrical Engineering, Focus on Remote Sensing and High Frequency Technology

- 2001 – 2006

- Friedrich-Alexander-University Erlangen-Nuremberg Erlangen, Deutschland, Scientific Assistant / Assistant, Department of High Frequency Technology

- 2005

- Friedrich-Alexander-University Erlangen-Nuremberg Erlangen, Germany, Doctorate in Engineering

- 2006

- Siemens Corporate Technology Erlangen, Germany, Developer High Frequency Electronics and Sensor System Consultant

- 2006 – 2010

- Siemens Healthcare, now Siemens Healthineers Erlangen, Germany, Developer Local Coil Development, Magnetic Resonance Imaging; Pre-Development, Product Development, Project Management

- Since 2012

- Siemens Healthcare, now Siemens Healthineers Erlangen, Germany, System Architect for Magnetic Resonance Imaging

- 2019

- Siemens Healthineers Erlangen, Germany, Principal Key Expert for System Architecture

Further Activities

- Since 2012

- Friedrich-Alexander-University Erlangen-Nuremberg Erlangen, Germany, Guest Lecturer, Medical Technology Application of High-Frequency Technology

Scholarships

- 1999 – 2000

- Scholarship of the Dr. Jürgen Ulderup Stiftung

- 1999 – 2000

- Scholarship Friedrich-Alexander-University Erlangen-Nuremberg

- 1999

- Admission to the Siemens International Student Program

- 1997 – 2001

- Scholarship German Academic Foundation (Studienstiftung des deutschen Volkes)

Patents

- 256 patent families, 685 individual patent applications filed in these patent families, of which 415 patent applications were already granted.

Publications

- 33 peer-reviewed publications in scientific journals and conference proceedings, including 11 as the first or last author

1 book chapter

Invitations as speaker (e.g. Plenary for “IEEE Conference on Antennas and Propagation“)

Ad hoc reviewer for several scientific journals

Awards

- 2013

- Inventor of the Year, Siemens AG

- 2016

- Appointment as Principal Key Expert for System Architecture, Siemens Healthineers

- 2010

- Appointment as Senior Key Expert for System Architecture, Siemens Healthcare, now Siemens Healthineers

Dr. rer. nat. David M. Grodzki

- July 7, 1984

- Born in Hannover, Germany

- 1996 – 2003

- Gymnasium St. Ursula-Schule Hannover, Germany, Qualification: High-school diploma

- 2004 – 2009

- Ludwig-Maximilians-University Munich, Munich, Germany, Diploma in Physics

- 2008 – 2009

- Siemens Healthcare, now Siemens Healthineers Erlangen, Germany, Diploma student, Business Development Magnetic Resonance Imaging

- 2009 – 2011

- Siemens Healthcare, now Siemens Healthineers Erlangen, Germany, PhD student, Application Pre-Development Magnetic Resonance Imaging

- 2012

- Julius-Maximilians-University Wuerzburg, Wuerzburg, Germany, Doctorate in Physics

- 2011 – 2014

- Siemens Healthineers Erlangen, Erlangen, Germany, Developer, Application Pre-Development Magnetic Resonance Imaging

- 2014 – 2021

- Siemens Healthineers Erlangen, Erlangen, Germany, Developer and Sub-Project Lead Research and Development Magnetic Resonance Imaging

- Since 2022

- Siemens Healthineers Erlangen, Erlangen, Germany, Team Lead Imaging Innovations & Image Quality, Pre-Development Magnetic Resonance Imaging

Scholarships

- 2010

- Ernst-von-Siemens PhD Grant

Further Activities

- Since 2021

- Friedrich-Alexander-University Erlangen-Nuremberg Erlangen, Germany, Guest Lecturer MRI at Erlangen University Hospital

Patents

- 212 patent families, 471 individual patent applications filed in these patent families, of which 283 patent applications were already granted.

Publications

- 29 peer-reviewed publications in scientific journals, including 9 as first or last author, and several conference proceedings

Several book chapters

Invitations as speaker (International conferences and symposia)

Ad hoc reviewer for several scientific journals

Awards

- 2019

- Inventor of the Year, Siemens AG

- 2022

- Appointment as Senior Key Expert for MRI Applications, Siemens Healthineers

Prof. Dr. med. Michael Uder

- October 29, 1966

- Born in Saarbruecken, Germany

- 1986

- High-school diploma, Gymnasium am Stadtgarten, Saarlouis, Germany

- 1989 – 1992

- Saarland University, Saarbruecken, Germany, Study of Human Medicine

- 1993 – 1999

- Saarland University Hospital Homburg, Germany, Resident, Department of Radiodiagnostics

- 1996

- Promotion

- 1999

- Qualification as Medical Specialist for Radiology

- 1999 – 2003

- Saarland University Hospital Homburg, Germany, Senior Physician and Assistant Medical Director, Department of Radiodiagnostics

- 2002

- Qualification as Postdoctoral Lecturer for Radiology

- 2003 – 2009

- Friedrich-Alexander-University Erlangen-Nuremberg Erlangen, Germany, Professor for Radiology

- 2003 – 2009

- Erlangen University Hospital, Erlangen, Germany, Assistant Medical Director, Institute of Radiology

- Since 2009

- Friedrich-Alexander-University Erlangen-Nuremberg Erlangen, Germany, Chair of Radiology

- Since 2009

- Erlangen University Hospital Erlangen, Germany, Director, Institute of Radiology

Further Activities

- Since 2007

- Editorial Board of “Röfo”, trade magazine for medical radiology

- Since 2012

- Editor “Gefäßmedizin Scan”, magazine for angiology, vascular surgery, diagnostic and interventional radiology

- Since 2012

- Member of the Board, German Roentgen Society

- Since 2012

- Director of the Academy for training and further education, German Roentgen Society

Awards

- 2009

- Wachsmann Award of the German Roentgen Society

- 2009

- Equality Award Friedrich-Alexander-University Erlangen-Nuremberg, Germany

- 2012

- Wachsmann Innovation Award of the German Roentgen Society

Contact

Coordination and Press

Kathrin Palder

Press Officer Innovation, Künstliche Intelligenz ´

und Therapie Communications

Siemens Healthineers AG

Karlheinz-Kaske-Str. 5

91052 Erlangen, Deutschland

Mobile: +49 (0) 173 / 36 45 319

E-Mail: kathrin.palder@siemens-healthineers.com

Web: https://www.siemens-healthineers.com/

Spokesperson

Dr.-Ing. Stephan Biber

Senior Systemarchitekt

Magnetic Resonance Imaging

Siemens Healthineers AG

Allee am Röthelheimpark

91052 Erlangen, Deutschland

E-Mail: stephan.biber@siemens-healthineers.com

Web: https://www.siemens-healthineers.com/magnetic-resonance-imaging

A description provided by the institutes and companies regarding their nominated projects

Open to all – a new MRT for the world

Magnetic resonance imaging for the whole world

Since the very first magnetic resonance imaging (MRI) examination was conducted in 1983, the only way has been up. Magnetic field strengths have increased, allowing for much clearer medical images and more accurate diagnoses. At the same time, however, higher field strengths have raised both the cost of this technology and its complexity. Forty years on, a team from Siemens Healthineers and Universitätsklinikum Erlangen, Germany, have devised a new platform that is turning the imaging technology on its head. Dr. Stephan Biber and Dr. David Grodzki from Siemens Healthineers, together with Prof. Michael Uder, MD, Head of the Institute of Radiology at Universitätsklinikum Erlangen, have cut the field strength to 0.55 Tesla, thereby improving global access to MRI.

Magnetic resonance imaging has revolutionized diagnostic imaging. In the case of rheumatism, for instance, it renders joint inflammation visible long before bone destruction can be detected on an X-ray. After a heart attack, an MRI scan can reliably determine where heart muscle can be saved by vascular surgery. In the case of liver tumors, it is possible to identify precisely healthy tissue that can be spared during surgery — and these are just a few examples of cases in which MRI facilitates reliable diagnoses that can improve therapy for patients. The procedure is particularly well suited for soft tissue imaging and is considered harmless to patients because it does not require radiation.

Unfortunately, however, more than half of the world's population does not have access to this technology. Cost is a factor, and many areas lack the infrastructure necessary to operate an MRI device. In many cases, a stable power supply or supply of liquid helium, both of which are essential for cooling the magnet inside the machine, cannot be ensured. Conventional MRI systems are also very large and extremely heavy, making them difficult or even impossible to install in many buildings. In addition, it is also not always easy to find qualified personnel to perform MRI examinations, which can be highly complex. The limited space inside an MRI system also presents challenges for certain people, such as children or individuals who are claustrophobic or obese.

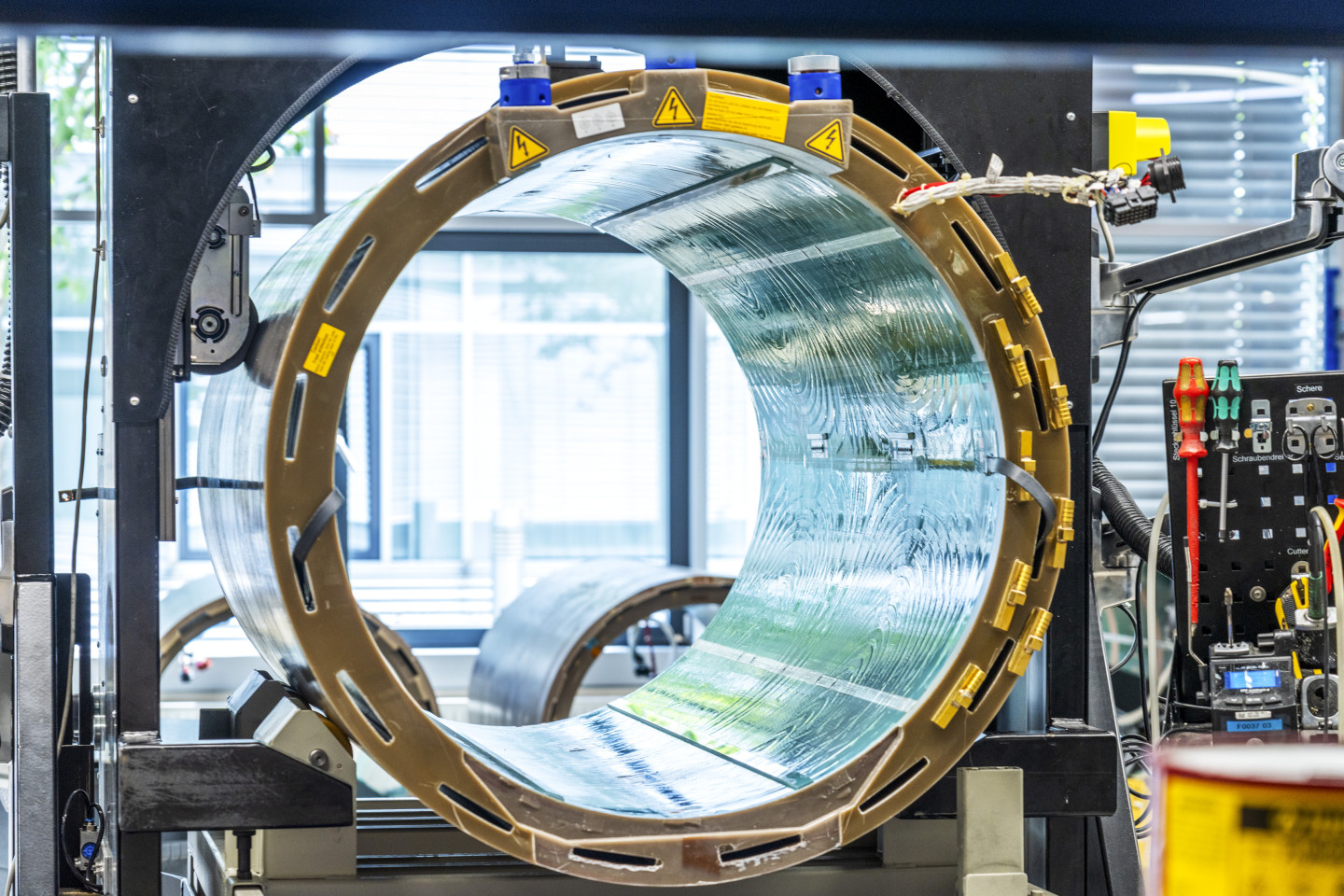

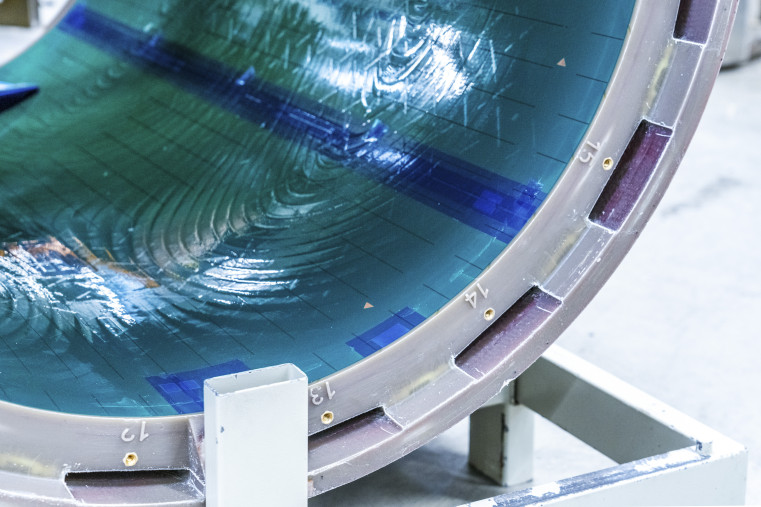

About six years ago, a research team from Siemens Healthineers led by Stephan Biber and David Grodzki began to challenge the general consensus that high field strength is the only way forward in MRI. Their aim was to fundamentally rethink the technology so as to make it accessible to more people. The result of their work is the MAGNETOM Free. Platform, which comprises the MAGNETOM Free.Max and MAGNETOM Free.Star systems. During development, Michael Uder began clinical testing of the new platform and oversaw the world's first clinical installation at Universitätsklinikum Erlangen, Germany.

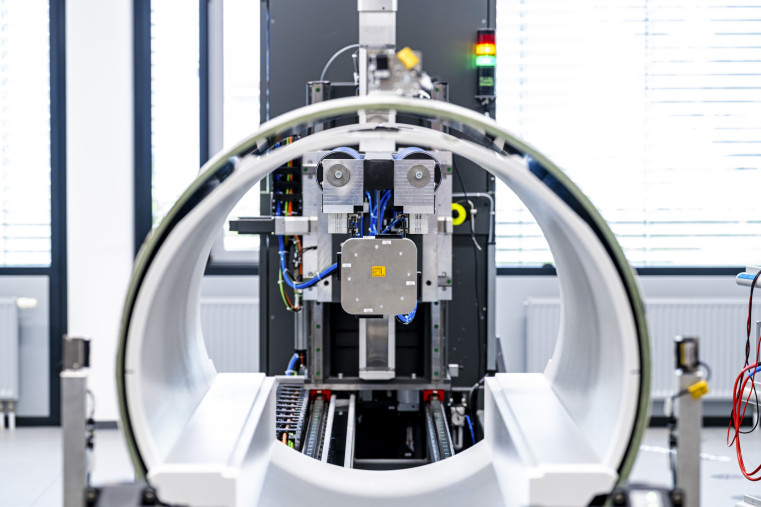

Field strength dilemma solved by innovative image reconstruction

The key requirement for the new platform was a lower magnetic field strength, which would reduce cost and complexity. Here, the challenge was to use a weaker magnetic field of 0.55 Tesla (T) to produce images with diagnostic quality comparable to that of conventional devices with field strengths of 1.5T and higher. However, lowering the field strength meant that measurement times would have to be extended to obtain images of high diagnostic value. To solve this dilemma, new acquisition techniques and image reconstruction methods based on artificial intelligence (AI) were developed for the new system platform. These include an image-based algorithm that provides higher resolution and a method for reconstructing MRI images directly from raw data, which can speed up image acquisition. A new time-saving application also allows images to be acquired simultaneously rather than sequentially, as is usually the case.

Closed helium cycle for sustainable magnet cooling

Another crucial innovation concerns the cooling of the magnet. Helium, which is used as a liquid coolant, is not only expensive, but it is also a scarce resource in many parts of the world. To address these issues, the new MRI systems incorporate a newly developed magnet technology that reduces the amount of liquid helium required from around 1,500 liters down to just 0.7 liters and allows it to be preserved in a closed circuit. This means that the new systems can be restarted automatically even after prolonged power failures without refilling the helium, as would be required with conventional MRI devices.

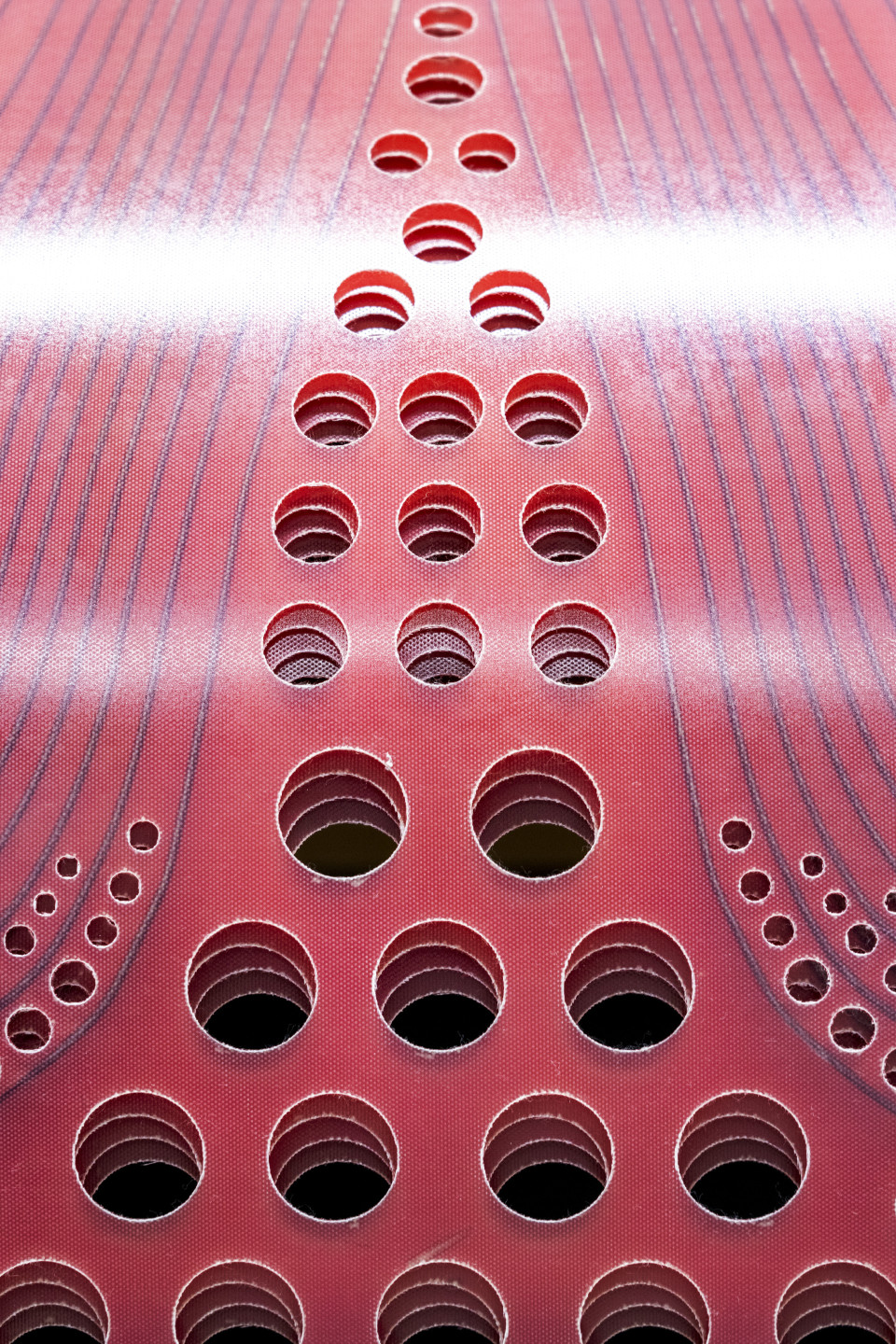

Compact product design for easy installation

Thanks to their compact design, the new MRI systems can be operated in places where MRI was not an option in the past. Weighing in at just under three metric tons with a footprint of only 24 square meters, the scanners are amongst the smallest, most lightweight full-body scanners on the market. They can even be installed in buildings with lower load-bearing floors and higher up in the building. In addition, the new systems can be transported through standard-sized doors of two meters in height and across existing corridors without having to remove doors and walls or even construct entirely new buildings.

Enlarged bore size and ease of use

By reducing the magnetic field strength, it was also possible to increase the bore size of MAGNETOM Free.Max to 80 centimeters, compared with 60 or 70 centimeters in earlier systems. This allows the system to accommodate claustrophobic and obese patients as well children, who can now better interact with their parents during the examination, while reducing the need for sedation.

Operating an MRI scanner is a complex process requiring a great deal of expertise. Yet there is a global shortage of trained staff. Therefore, a highly automated and simplified user interface has been developed especially for the innovative new system platform. It is designed to help prevent operating errors while automated algorithms are used to adapt the image acquisition to specific organs.

A new class of magnetic resonance imaging systems

Stephan Biber, David Grodzki, and Michael Uder have developed a new class of MRI scanners and integrated them into routine clinical practice. Two years after their market launch, these devices are available in many countries. Installations include hospitals in Brazil, India, Yemen, and Angola. The new systems have improved access to MRI in Germany, too. In the pediatric radiology department of Universitätsklinikum Erlangen, the compact design of the new system allowed it to be installed in a room near the intensive care unit to simplify patient exams. Technologies developed specifically for the MRI platform, such as AI-based image reconstruction, are already available for other MRI systems from Siemens Healthineers used in areas such as cardiac imaging and clinical research. In the medium term, the closed helium circuit and compact design will play a key role in other model series developed and manufactured in Erlangen, Germany.

Siemens Healthineers AG (listed in Frankfurt, Germany: SHL) pioneers breakthroughs in healthcare. For everyone. Everywhere. As a leading medical technology company headquartered in Erlangen, Germany, Siemens Healthineers and its regional companies are continuously developing their product and service portfolio, with AI-supported applications and digital offerings that play an increasingly important role in the next generation of medical technology. These new applications will enhance the company’s foundation in in -vitro diagnostics, image-guided therapy, in -vivo diagnostics, and innovative cancer care. Siemens Healthineers also provides a range of services and solutions to enhance healthcare providers’ ability to provide high-quality, efficient care. In fiscal 2022, which ended on September 30, 2022, Siemens Healthineers, which has approximately 69,500 employees worldwide, generated revenue of around €21.7 billion and adjusted EBIT of almost €3.7 billion. Further information is available at www.siemens-healthineers.com.

The right to nominate outstanding achievements for the Deutscher Zukunftspreis is incumbent on leading German institutions in science and industry as well as foundations. The project "Open to all – a new MRT for the world” was submitted by Deutsches Patent und Markenamt.

Federal President Frank Walter Steinmeier will present the Deutscher Zukunftspreis to one of the three nominated teams on November 22, 2023.

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache