Nominee 2014

Ionenkanalmessung im Hochdurchsatz

Dr. Niels Fertig, Dr. Andrea Brüggemann, physicist Michael George, and their team developed an innovative system that automates and considerably simplifies the detection of medical active ingredients: the "SyncroPatch 384/768PE" robotic platform. The system is used to test numerous ingredient candidates at the same time and simultaneously on hundreds of cells. This is a major breakthrough in the industrial search for new drugs. Niels Fertig founded Nanion Technologies GmbH in 2002 as a spin-off of the Center for NanoScience at Ludwig-Maximilians-Universität (LMU) Munich and is the company's Chief Executive Officer. Andrea Brüggemann is Chief Scientific Officer and Michael George is Chief Technology Officer at Nanion.

In the past, the development of a new drug from basic research to market readiness took up to twelve years and cost on average around € 800m. One of the reasons was the expensive and time-consuming analysis of millions of substances considered as potential active pharmaceutical ingredients.

more details

Resumes

Dr. rer. nat. Niels Fertig

- 22.12.1972

- Born in Hamburg

- 1992

- Abitur

- 1992 – 1993

- Civil Service civil service in the University Hospital Göttingen

- 1993 – 1995

- Studying Physics, Georg-August-University, Göttingen

- 1995 – 1996

- Studies at the University of California, San Diego, United States

focus: artificial neural networks, Nonlinear Dynamics

- 1996

- Researcher at the Scripps Institute, San Diego, United States

- 1996 – 1999

- Studying physics at the Ludwig-Maximilians Universität, Munich

Scholarship of the German Academic Foundation - 1998 – 1999

- Diploma thesis at the Institute of semiconductor physics, Ludwig-Maximilians – University, Munich: "Nanostructured probe for single ion channels in cell membranes"

- 1999 – 2002

- Promotion at the Center for NanoScience, Munich: "Development of biochips for electrophysiological investigations of ion channels"

PhD Scholarship of the German Academic Foundation - 2002

- Founding of Nanion technologies GmbH, Munich since

- 2002

- CEO of Nanion technologies GmbH, Munich (English)

Honors:

- 2001

- Genius Biotech Award of Baden-Württemberg

- 2001

- 3rd place at Business-Plan-Contest for Microsystems Technology

start2grow (Nordrhein-Westfalen) - 2003

- iKuh award for applied Nanotechnology

- 2005

- Nanoscience award 2005

- 2005

- Nanion Technologies GmbH: Innovation Award of the Bavarian Volks- and Raiffeisenbanken: SME of the year 2005

- 2006

- Nanion Technologies GmbH: Nominated for the Bavarian Innovation Award,

Recognition-Award for outstanding innovative achievements - 2007

- Nominated for the Deutscher Zukunftspreis (German Future Prize, Federal President's Award for Technology and Innovation)

- 2008

- Nanion Technologies GmbH: Innovation award of the German economy, finalist in the category of startup

- 2009

- Nanion Technologies: Step Award

- 2009

- Nanion Technologies GmbH: German Founder's prize, winner in the category Newcomer

Dr. rer. nat. Andrea Brüggemann

- 13.06.1966

- Born in Hagen

- 1986

- Studying physics at the Ruhr-University Bochum

- 1991

- Start of the Diploma Thesis at the Center for Molecular Neurobiology in Hamburg (ZMNH)

- 1993

- Continuation of the Diploma Thesis at the Max Planck Institute for Experimental Medicine, Göttingen: "Isolation and electrophysiological characterization of the putative potassium channel ether-à-go-go from Drosophila Melanogaster”

- 1994

- Diplom, Ruhr-University Bochum

- 1994 – 1997

- Dissertation at the Max Planck Institute for Experimental Medicine, Göttingen: "Investigation of the voltage-dependent potassium channel rEAG under the influence of the Cell Cycle"

- 1997

- Research stays of several months in Spain

- 1997

- Disputation in physics at the Ruhr-University Bochum

- 1997

- Postdoc at the Max Planck Institute for Experimental Medicine, Department of Molecular Biology of Neuronal Signals, Göttingen

- 1993 - 1997

- Scholarship of the Max-Planck-Society

- 1998

- Post-doc in the Cardio-Vascular Research Department at Sanofi-Aventis (Hoechst Marion Roussel), Frankfurt

- 1999

- Laboratory head in the Cardio-Vascular Research Department at Sanofi-Aventis Germany, Frankfurt

- 2001

- Head of the Ion Channel Platform at Sanofi-Aventis Germany, Frankfurt

- 2002

- Head of the Biological Department at Cytion SA, Epalinges, Switzerland

- since 2003

- Managing Director and CSO Nanion Technologies GmbH, Munich

Dipl. Phys. Michael George

- 25.05.1970

- Born in Bremerhaven

- 1989

- Abitur

- 1989 – 1991

- Civil service, Werkstatt Pronova, Munich

- 1991 – 1998

- Studying physics and biophysics, Ludwig-Maximilians University Munich

- 1996 – 1998

- Diploma Thesis, Institute for Biophysics, Ludwig-Maximilians University Munich

“Investigations for noninvasive membrane potential measurement with the Light addressable potentiometric sensor”

- 1998 – 2002

- Research associate, Center for Nanoscience CeNS, Ludwig-Maximilians University Munich

- since 2002

- CTO, Nanion Technologies GmbH, Munich

Contact

Spokesperson

Dr. Niels Fertig

Nanion Technologies GmbH

Gabrielenstraße 9

80636 München

Phone: +49 (0) 89 / 21 89 97 972

E-Mail: niels@nanion.de

www.nanion.de

Press

Cecilia Farre

Nanion Technologies GmbH

Gabrielenstraße 9

80636 München

Phone: +49 (0) 89 / 21 89 97 971

E-Mail: Cecilia@nanion.de

www.nanion.de

A description provided by the institutes and companies regarding their nominated projects

In recent years, the team around Dr. Fertig in their spin-off company Nanion Technologies GmbH from the University Munich, achieved to make a highly complex, biological cell analysis method compatible with requirements and standards of the pharma and biotech industry. The developed technology enables automated high throughput screening of potential drug candidates by highly parallel analysis of compound effects on cells and proteins. This dramatically speeds up the drug development process.

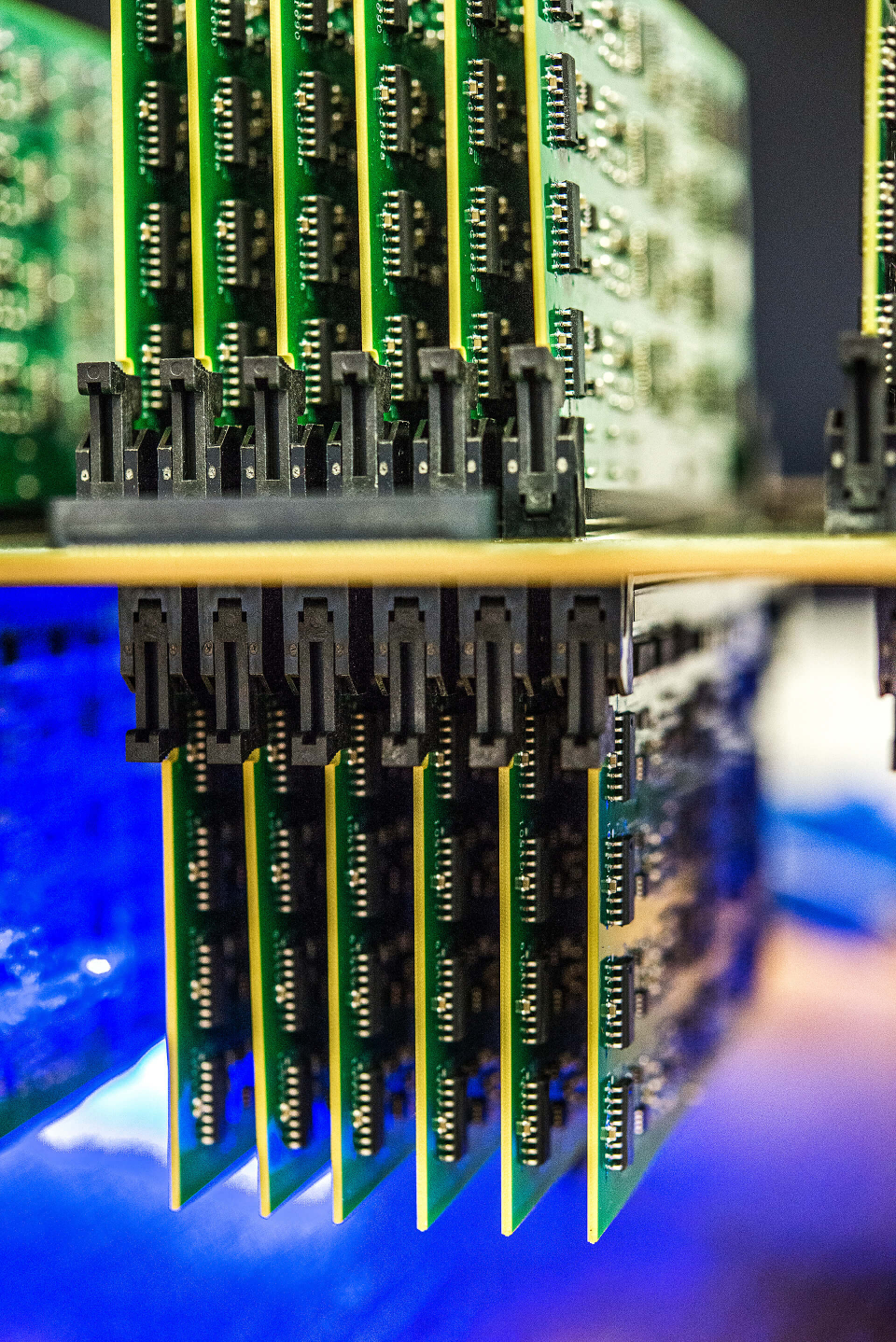

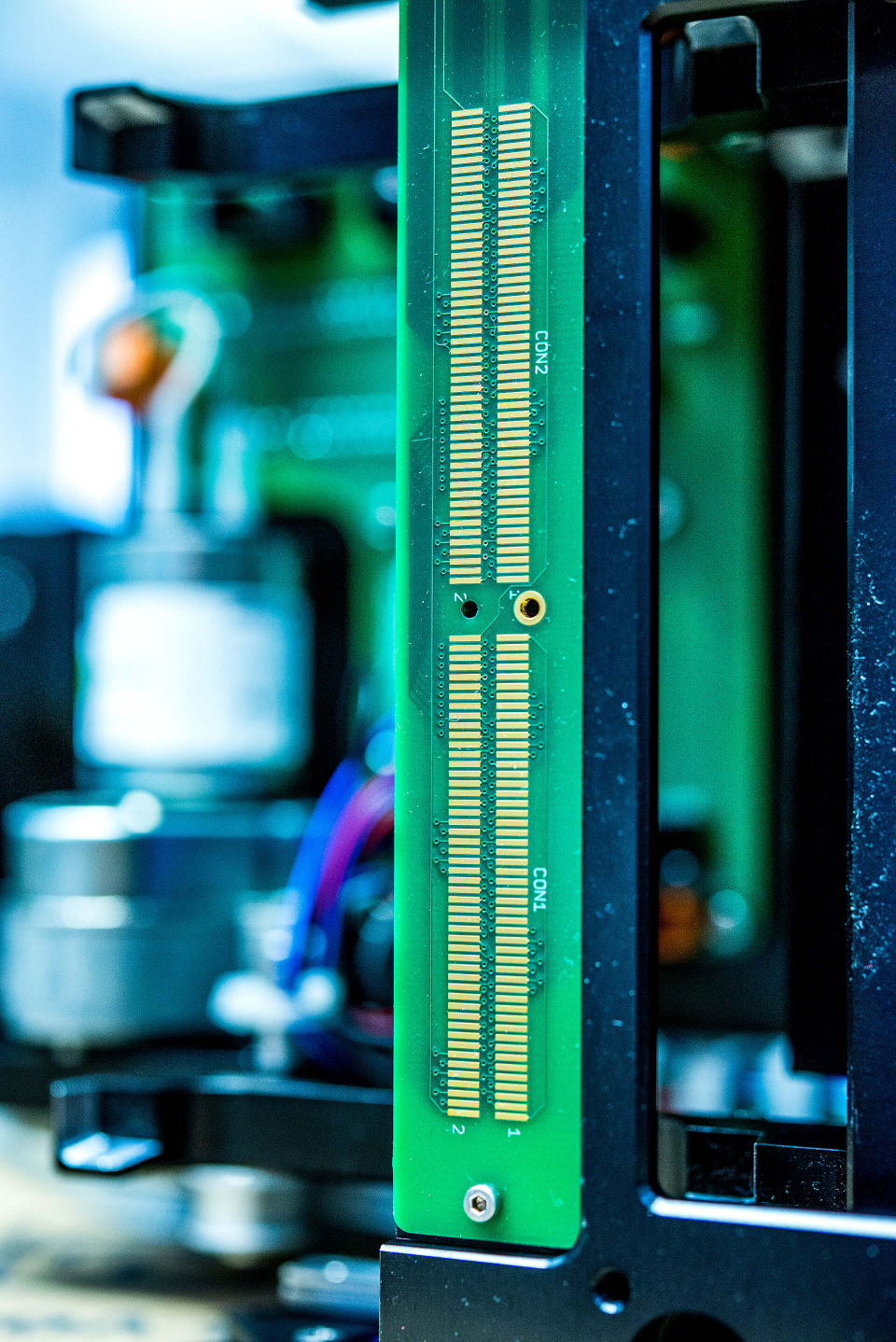

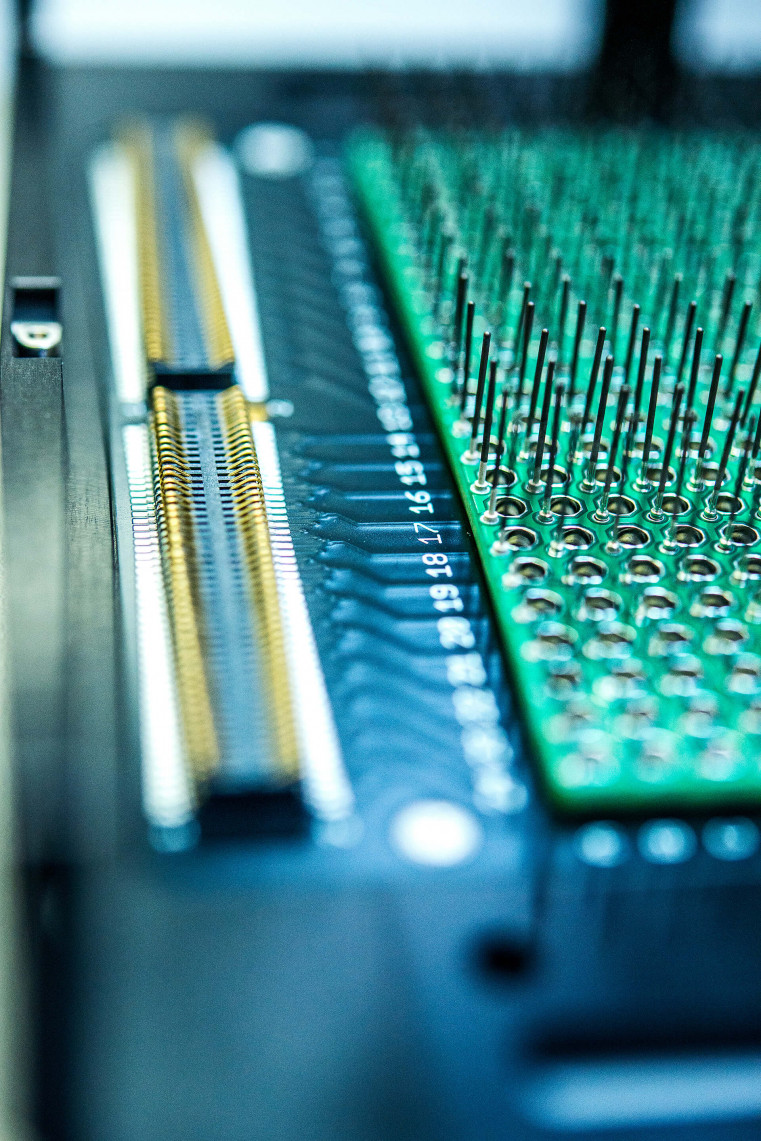

The team (Andrea Brüggemann, Michael George und Niels Fertig) did transfer the so called patch clamp technique for analysis of ion channels in cell membranes (developed by Erwin Neher und Bert Sakmann, Nobel Prize in Medicine 1991) into a chip-based biosensor format to optimize and facilitate the method. For this first step they were already nominated for the Federal Presidents German Future Prize in 2007. In the following years, this technology was further scaled for high throughput and was consequently adapted to industrial drug screening needs. With the development of a miniaturized, modular system, the SyncroPatch 384/768PE, and its integration in fully automated robotic platforms, all the advantages of the chip-based patch clamp technique are now completely realized and implemented. This indeed enables highly efficient, parallel ion channel screening with the chip-based approach in the industry standard of the microtiter plate format. The effects of new drug candidates on cells and ion channel proteins can thereby be measured in a more precise, more cost efficient and much faster way.

Background

Drug development is a long and very expensive process: often it takes more than a decade before a new drug enters the market and development costs average to more than a billion dollars. Every drug interacts with a certain part of the body, typically referred to as target, where the drug binds and modulates the course of disease. But to find the one drug that does the job – without harmful side effects on other parts of the body – a long process is required to screen up to millions of compounds for the potential drug candidate. One of the most important class of drug targets are ion channels. The most direct method to analyze ion channels is the patch clamp technique. But the required resources in terms of complex apparatuses and especially time and labor needed for experiments are very high, as only single cells are analyzed sequentially in the conventional method. So scaling to high throughput for industrial applications was not possible.

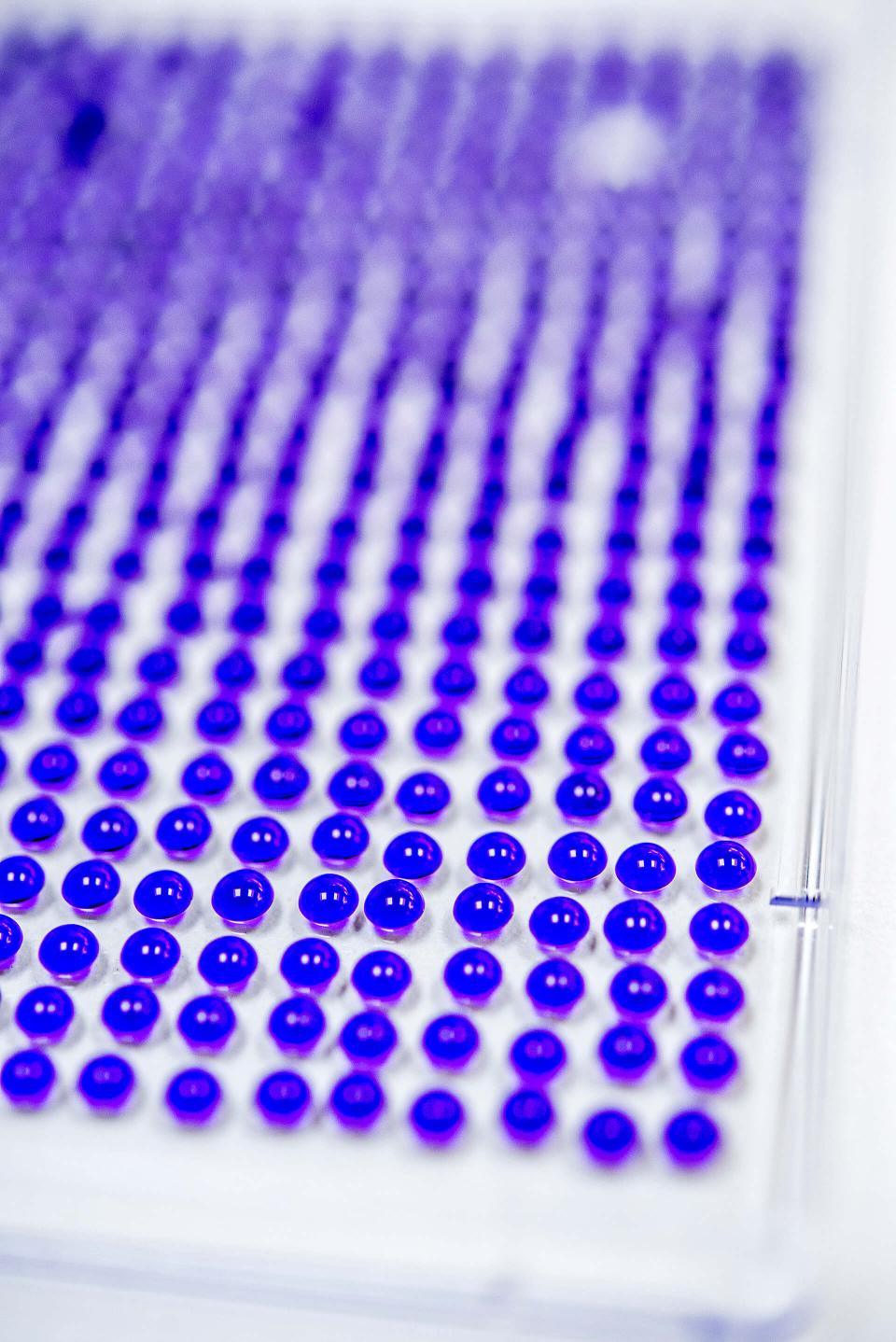

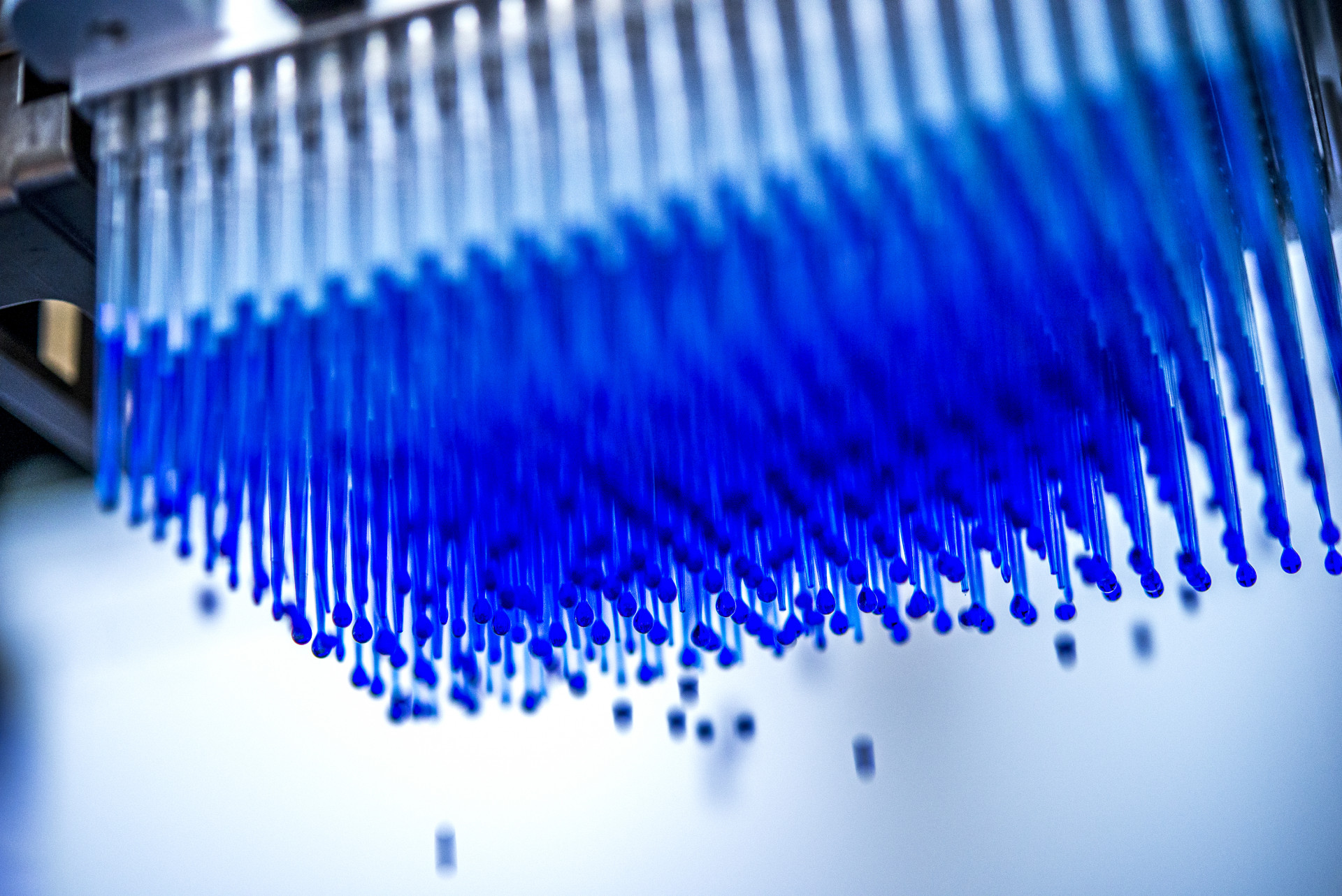

Only the new platform developed by the team from Nanion Technologies overcomes this limitation. In the SyncroPatch 384/768PE, cells and compounds are pipetted into small micro reaction chambers (384-fold in parallel), where micro-chips containing biosensors for patch clamping are situated. 384 cells are positioned individually on theses biosensors, which have a size of only about one micrometer, are electrical contacted and drug compound effects are analyzed, all that in a fully automated manner. In addition, one can even integrate two of such 384 channel patch clamp modules in one robot. This modular approach makes the technology indeed scalable, e.g. enabling the analysis of 768 cells in parallel when using two modules. With the SyncroPatch more than 20.000 compounds can be screened during a single day and costs per data point are dramatically decreased to less than 20 Cents per measurement. This parallel high throughput method provides early on detailed information on the activity of the drug candidates. The longsome screening process is drastically shortened and development costs are decreased. Furthermore, the SyncroPatch enables measurements on advanced cell types like e.g. stem cells, which makes the instrument not only attractive for pharma screening but also for academic research and personalized medicine.

The first SyncroPatch 384 systems (and actually also a SyncroPatch 768 with two modules) were sold and shipped directly upon product launch at the end of 2013 to Bayer HealthCare AG and Bayer CropScience AG. In 2014, more systems were supplied to numerous pharma companies in Europe, USA und Asia as well as to academic research institutes. The extraordinarily positive customer feedback and strong market resonance document the enormous potential of the technology and the corresponding growth potential for Nanion Technologies.

The SyncroPatch technology from the Nanion team is a real quantum leap: only a few years ago, it was thought impossible by anyone skilled in the art that the very manual and demanding patch clamp technique could ever be automated and scaled in this manner. This revolutionary development represents a major breakthrough for ion channel drug discovery and therefore by means of innovative drugs eventually a huge value for medical care and society.

This development is also a striking example for a complete cascade of technology creation: based on scientific results from academic research a spin-off company is started, where a powerful technology is developed and customer oriented products employing this technology are introduced and established very successfully in the global market. Nanion Technologies today employs more than 60 highly qualified employees, the company is very profitable, has started subsidiaries in USA and China and displays strong, sustained growth dynamics.

This development documents the innovation potential of the German science and research landscape and the great opportunity to consequently convert innovation into economic strength in Germany.

About Nanion Technologies:

Nanion Technologies is a one-stop-shop for ion channel drug discovery and screening technologies as well as sophisticated research instrumentation. Nanion was founded in 2002 as a spin-off from the Center for Nanoscience (CeNS) of the University of Munich. Nanion’s team has developed and successfully established four generations of automated patch clamp instruments for sophisticated and high throughput applications in ion channel research and drug discovery (Port-a-Patch, Patchliner and SyncroPatch product families). Further product lines are for cardiotoxicity screening (CardioExcyte 96), for parallel bilayer recordings (Orbit 16), and for parallel membrane transporter protein recordings (SURFE2R). Since 2014, Nanion carries Axion’s multi-electrode array (MEA) systems in Europe and China.

Contact Nanion Technologies:

Dr. Niels Fertig, CEO, Phone: +49 89 2189 97972, Email: info@nanion.de, Web: www.nanion.de

Press contacts: Dr. Cecilia Farre, Marketing Director, Phone: +49 89 2189 97973, Email: info@nanion.de

Nanion is a German Private Limited Company

The right to nominate outstanding achievements for the Deutscher Zukunftspreis is incumbent upon leading German institutions in science and industry as well as foundations.

The project “Ion channel screening with high throughput – from university bench to global player” was nominated by acatech – National Academy of Science and Engineering e.V..

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache