Nominee 2024

Power for the energy transition

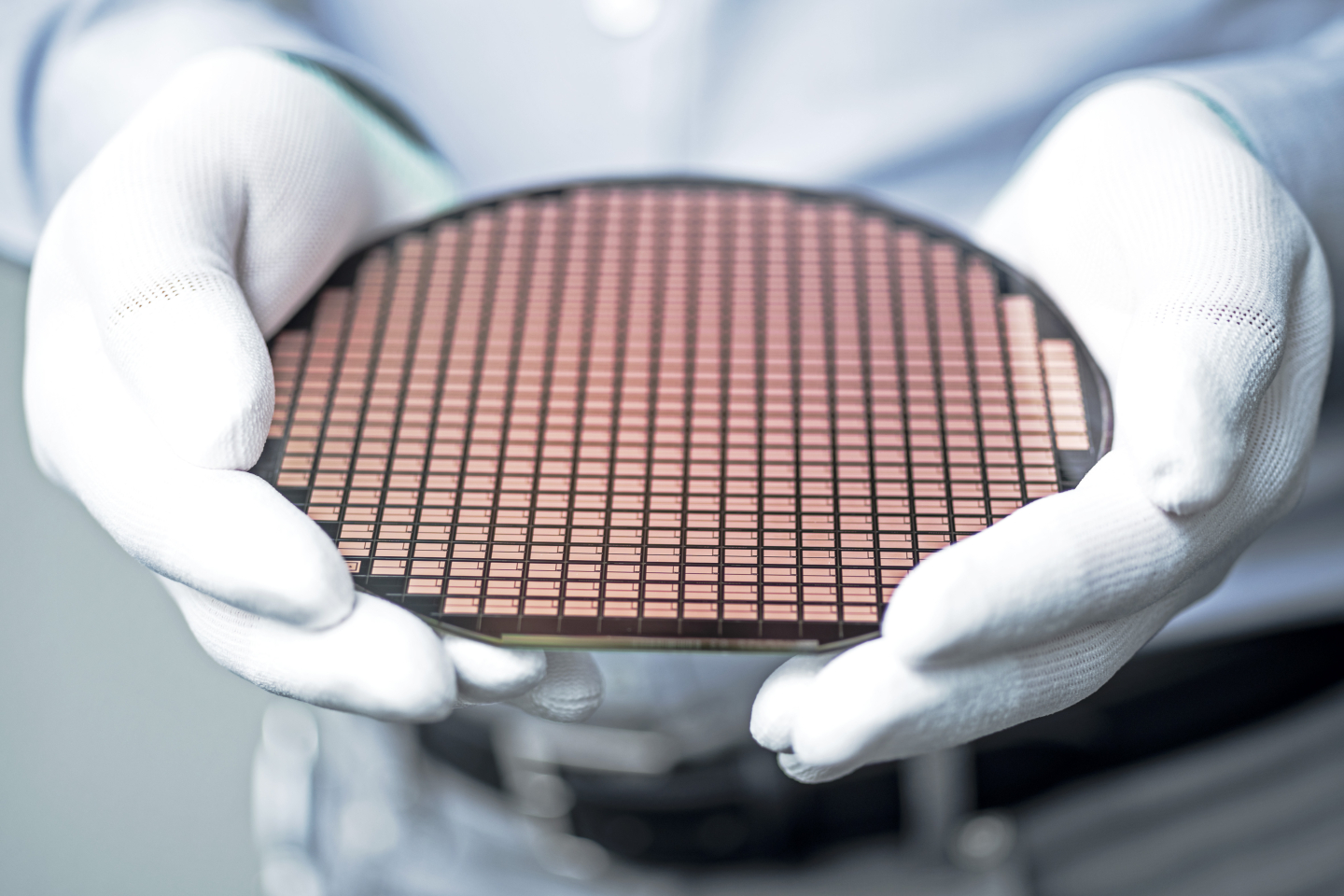

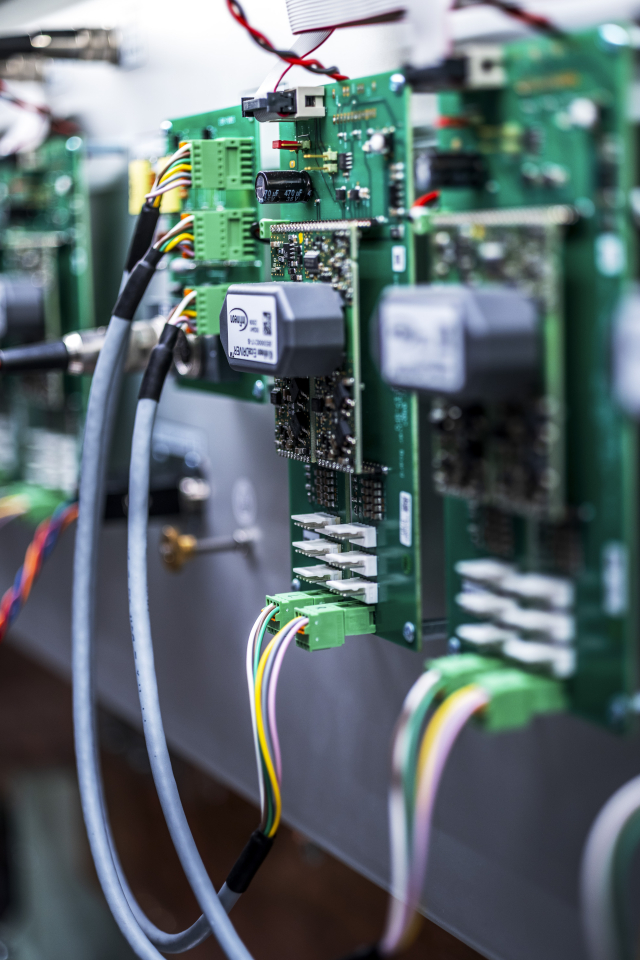

However, the basic prerequisite for a successful energy transition is that the electrical energy is generated from renewable sources such as solar or wind and can be regulated and controlled as efficiently as possible. This requires powerful and reliable switching units, so-called power converters, which consist of many electronic components. At the heart of a power converter is a module with chips made of a semiconductor material - the so-called power semiconductor, which switches the current.

Controlling electrical energy is not just about switching it on and off in the same way that we operate a light switch. Rather, it is about varying the current, voltage or frequency in a targeted manner. Vehicles, for example, whether on the road or rail, must be able to regulate their speed, accelerate and decelerate. Simply switching the energy flow on and off is not enough; regulation is required here. The power semiconductors in the power converters are used for this purpose, but they have to switch very frequently per unit of time, sometimes many thousands of times a second. However, each of these switching operations results in losses of electrical energy, which then heat up the module. The consequences are: Energy is lost and complex cooling is required to prevent the module from being destroyed.

The team was able to remedy this with a new material for the power semiconductor: silicon carbide instead of silicon. Electrically, this material offers many advantages over pure silicon. For example, a module made from this material can process significantly higher current flows with the same size. In addition, the losses that occur during each switching operation are significantly lower. During development, it was found that the switching losses could be reduced by 90%. This makes cooling the module easier and cheaper. Simple air cooling is often sufficient instead of expensive water cooling.

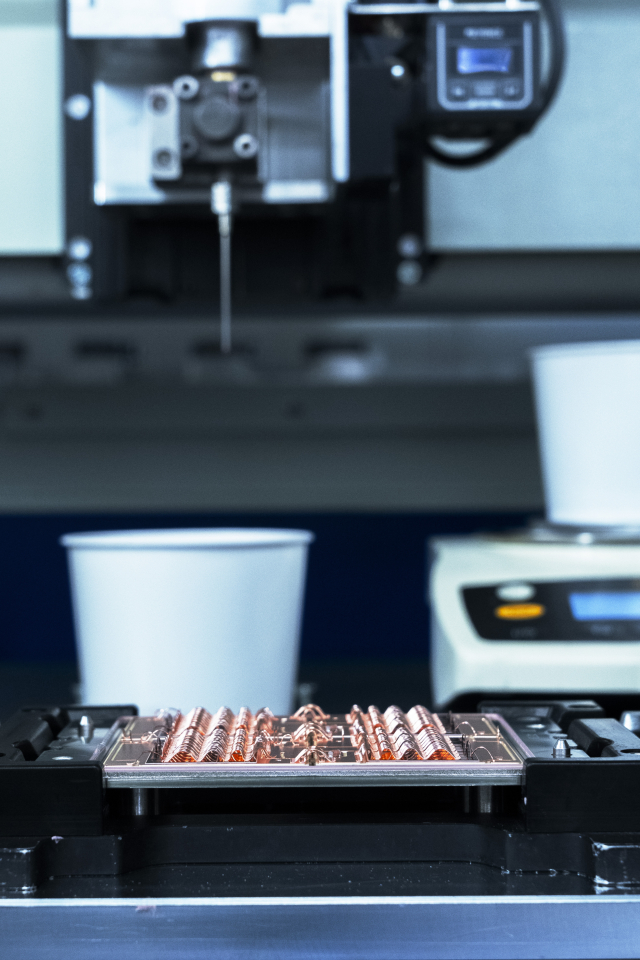

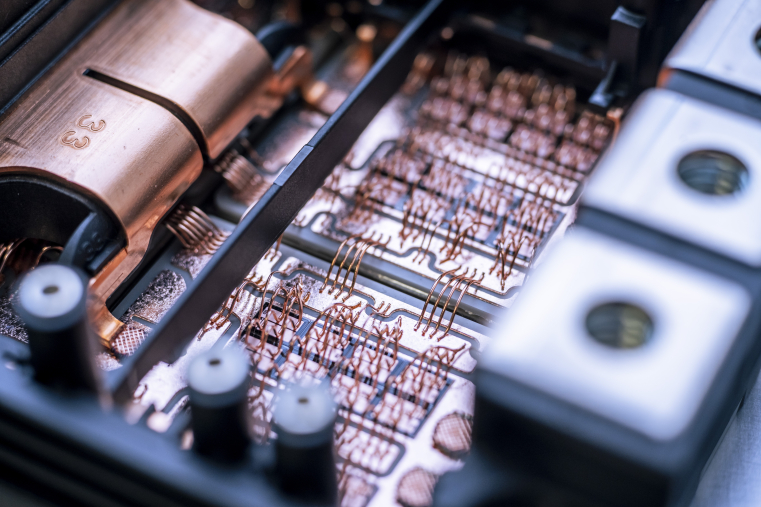

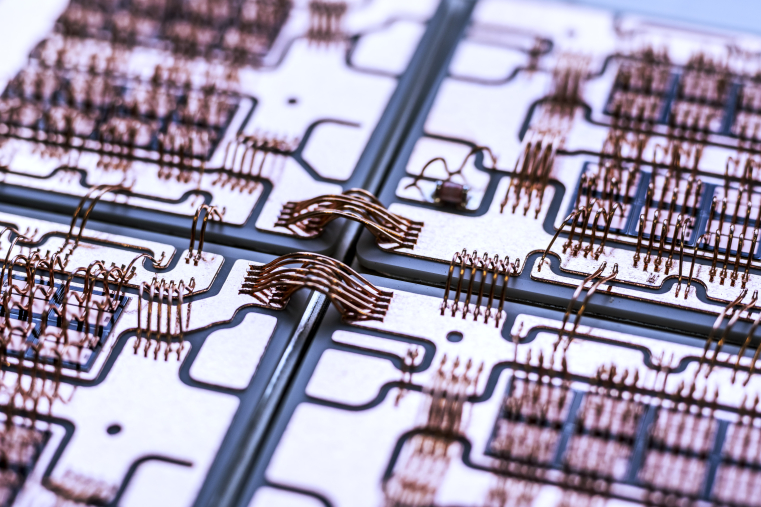

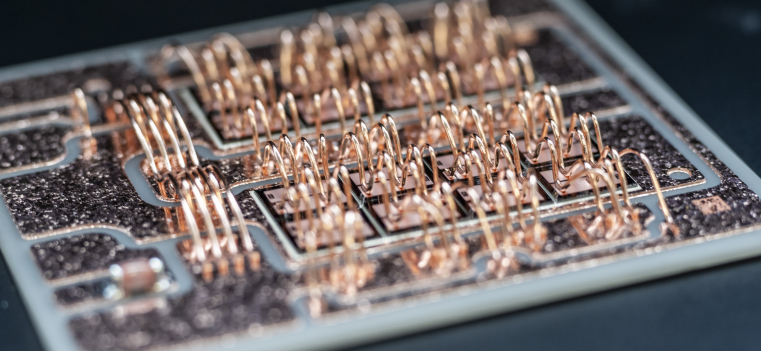

However, the new material also has some drawbacks. Silicon carbide is very hard and brittle, it is difficult to manufacture, which results in high production costs. In addition, silicon carbide has a high thermal conductivity and a high coefficient of thermal expansion. This means that the material expands considerably when heated. This physical fact results in an enormous challenge: in the module, the current must first be conducted to the semiconductor and then dissipated again. In silicon-based power electronics, thin aluminum wires are usually used for this purpose, a highly conductive metal that can be easily connected to the semiconductor. If the semiconductor moves due to thermal expansion, the contact metal must elastically compensate for this movement. However, due to the unfavorable material parameters and high energy density of silicon carbide, aluminum cannot achieve this over the required service life of 35 years.

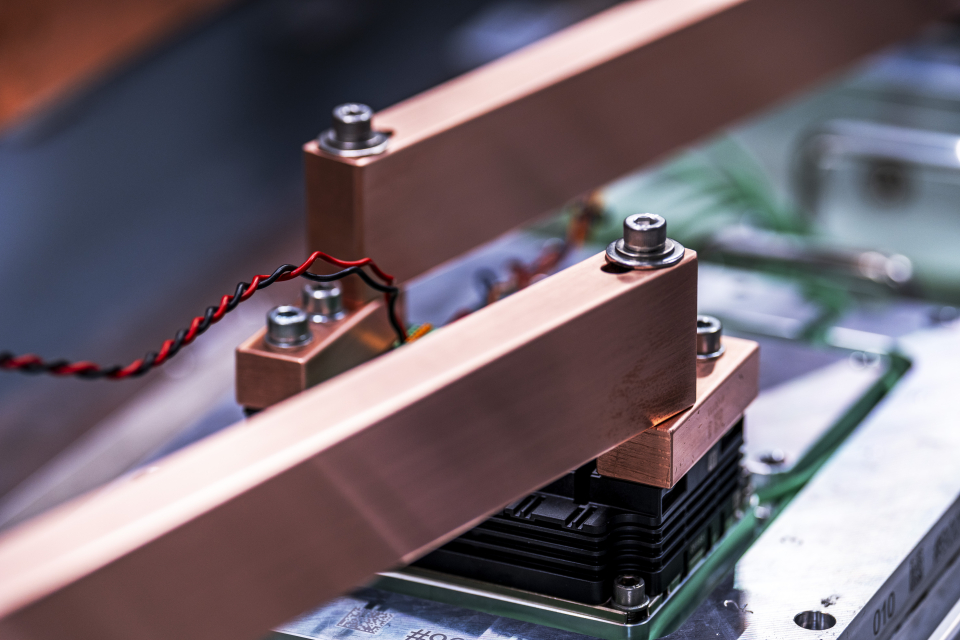

The wire detaches from the chip and the system fails. A different, highly conductive metal with the corrsponding plasticity had to be used. Copper fulfills these mechanical conditions. This contact metal not only solved the problem - its reliability exceeds the state of the art tenfold. However, this created a new challenge. When copper and silicon carbide come into direct contact, copper atoms diffuse into the semiconductor material and destroy it. To prevent this from happening, a completely new concept had to be found for the chip design and the bonding, i.e. the connection between the metal and the semiconductor.

More Details

Resume

Dr. rer. nat. Konrad Schraml

Dec. 2, 1986

Born in Kemnath / Kastl, Germany

2006 – 2009

Degree program in Engineering Physics at Technical University of Munich, specialization in Energy Sciences and Radiation Biophysics

Degree: Bachelor of Science2009 – 2011

Degree program in Engineering Physics at Technical University of Munich, specialization in Semiconductor Physics and Nanosystems

Degree: Master of Science2011 – 2015

Doctoral candidate at Technical University of Munich's Walter Schottky Institute in Garching / Munich

2016

PhD as Doctor of Natural Sciences in Experimental Semiconductor Physics at Technical University of Munich;

Dissertation subject: Coupling of Semiconductor Quantum Dots to Metallic Nanostructures2015 – 2022

Project manager and chip developer for power semiconductor modules at Infineon Technologies AG, Neubiberg / Munich, product development, project management and design engineer for silicon and silicon carbide-based power electronic components

2018

Appointed Project Manager – Power Device Development at Infineon Technologies AG, Neubiberg / Munich

2021

Appointed Senior Project Manager – Power Device Development at Infineon Technologies AG, Neubiberg / Munich

Since 2023

Manager in chip development department for power semiconductor modules at Infineon Technologies AG, Neubiberg / Munich

2024

Appointed Director – Power Device Development at Infineon Technologies AG, Neubiberg / Munich, responsible for power semiconductor module chip development roadmap

Patents

16 published patent applications in 5 patent families

Publications

13 publications in scientific journals and conference proceedings

Honors and awards

2006

German Physical Society (DPG) Abiturpreis

2011

Doctoral scholarship from the International Graduate School of Science and Engineering

2021 + 2022

Infineon Technologies AG Innovation Award in the field of power semiconductor modules

Prof. Dr.-Ing. Thomas Basler

April 19, 1985

Born in Greiz, Germany

2003 – 2009

Degree program in Electrical Engineering, specialization in Energy Technology at Chemnitz University of Technology

Degree: Graduate Engineer (Diplomingenieur), Focus: Robustness of high power diodes2009 – 2013

Research associate at the Professorship for Power Electronics and Electromagnetic Compatibility at Chemnitz University of Technology

2014

PhD as Doctor of Engineering at the Chemnitz University of Technology; Dissertation subject: Robustness of high-voltage power transistors (IGBTs)

2014 – 2020

Development engineer at Infineon Technologies AG, Neubiberg, product development, project management and design engineer for power electronic components based on silicon and silicon carbide

Since 2020

Professor of Power Electronics at the Chemnitz University of Technology

Since 2021

Co-founder and managing board member of Chemnitz Power Labs GmbH

Other activities

Since 2018

Member of JEDEC Task Groups (JC-70.2) for SiC topics

Since 2020

Member of the Board of Directors of the Center for Micro and Nano Technologies (ZfM) at Chemnitz University of Technology

Since 2020

Member of the Management Board (Leitungskreis) of the Freiburg Semiconductor Colloquium

Since 2021

Member of the technical committee of the International Reliability Physics Symposium (IRPS) for silicon carbide topics

Since 2022

Member of the expert group Q1 Power Electronics of the Society for Energy Technology within VDE

Since 2024

Member of the Board of Directors, PCIM Europe Conference for Power Electronics

Patents

134 published patent applications in 34 patent families

Publications

100+ publications in scientific journals and conference proceedings

1 book chapter on the robustness of silicon carbide power components

Reviewer for various journals and conferences (e.g. IEEE TED, IEEE TPEL, IEEE TDMR, IEEE EDL, IET Power Electronics)

Honors and Awards

2010

Prize for the Best Degree Project (Diplomarbeit) of the Institute for Electrical Engineering, Chemnitz University of Technology: "Robustheit von SPEED-Dioden" (Robustness of SPEED Diodes)

Dr. rer. nat. Caspar Leendertz

Oct. 19,1978

Born in Munich

2000 – 2007

Degree program in Physics at Free University of Berlin

Degree: Graduate degree (Diplom) in Physics2008 – 2011

Doctoral candidate at Helmholtz-Zentrum Berlin, Institute Silicon Photovoltaics, Research activities on efficiency-limiting recombination processes in heterostructure and thin-film solar cells based on silicon

2011

PhD as Doctor of Natural Sciences in Physics, TU Berlin

2011 – 2014

Scientist at Helmholtz-Zentrum Berlin, Institute Silicon Photovoltaics, research as part of a European project on nanotechnologies in photovoltaics, expert for electrical and optical simulation of solar cells and for simulation development

2014 - 2017

Senior Engineer at Infineon Technologies AG, Neubiberg

Electrical component simulation as part of product development for silicon- based power semiconductors2017 - 2020

Staff Engineer at Infineon Technologies AG, Neubiberg, project management, conceptual development and simulation in product development and pre-development of power semiconductors for high voltages (1.7…3.3 kV) based on silicon carbide

Since 2020

Principal Engineer at Infineon Technologies AG, Neubiberg

pproject management, conceptual development and simulation in product development and pre-development of new generations of power semiconductors based on silicon carbide

Patents

118 published patent applications in 32 patent families

Publications

38 publications in scientific journals and conference proceedings

Honors and awards

2007

SolarWorld Einstein New Talent Award for degree dissertation project on solar cell research, presented by SolarWorld AG as part of EUPVSEC 2007, Milan, Italy

2021

Infineon Technologies AG Innovation Award in the field of power semiconductor modules

Contact

Press

Iris Musiol

Senior Manager Marketing Communications

Am Campeon 1-15

85579 Neubiberg

Mobile: +49 (0) 151 / 51 44 77 08

E-Mail: iris.musiol@infineon.com

Web: www.infineon.com

A description provided by the institutes and companies regarding their nominated projects

Power for the energy transition – Electrifying large-scale drives with revolutionary chips that save energy

Power semiconductors are a core component in the energy transition: They regulate the flow of power along the entire electric energy chain, from the energy source all the way to the end device. The silicon chips which are used to do this however account for a major share of electric energy loss and impose limitations on the power density of the power converters available today. A joint team from Infineon and Chemnitz University of Technology has successfully developed an innovative energy-saving 3300V chip made from silicon carbide. It features innovative copper contacting and reduces switching losses by 90% while simultaneously increasing reliability by ten times. This not only saves enormous amounts of energy, the new module's significantly higher power density also makes it possible to electrify larger drives which have until now been the exclusive domain of fossil fuels.

Power converters are used to intelligently switch and modify the flow of electricity anywhere that electrical energy is generated, transmitted or consumed. Regardless of whether voltage, current or frequency is being modified, power semiconductors are at the heart of every such system, installed in modules varying in size according to power class. In their classic form, these modules contain two different types of chips: A transistor and a diode, both of which are usually based on silicon. In spite of much further development over time, these chips still cause very high levels of loss when conducting and switching electricity. Accordingly, the modules require efficient cooling; they are also a limiting factor when it comes to energy efficiency and the electricity that can flow through the system.

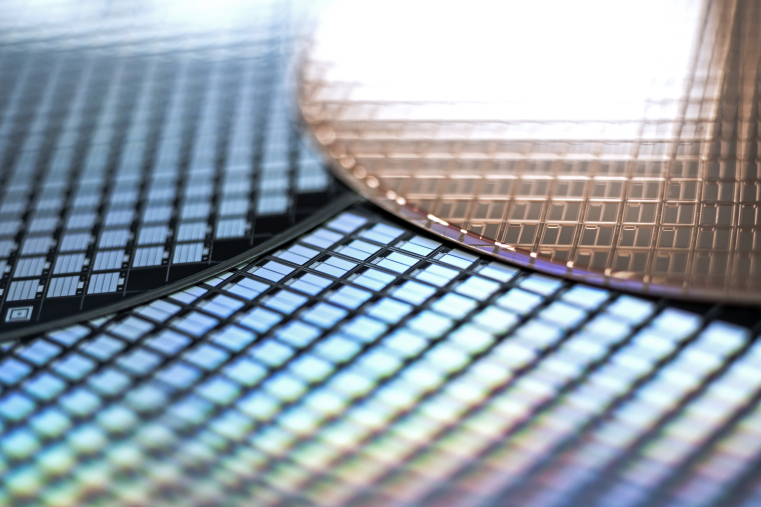

Silicon carbide: A new power semiconductor material

A new material, silicon carbide, provides a solution. Compared to silicon, silicon carbide can accommodate ten times more voltage per unit length without being destroyed. This makes it possible to give silicon carbide chips significantly smaller dimensions, resulting in higher power densities and considerably lower levels of loss. Although this material has been the subject of research and development for decades already, technical and economical obstacles have as yet prevented a breakthrough in the power semiconductor market for high currents and voltages. Silicon carbide is a very hard and brittle material which is very difficult to process, resulting in high levels of effort and high manufacturing costs. Furthermore, silicon carbide has a high coefficient of thermal expansion and is highly rigid. Power semiconductors constantly heat up and cool down again when operating, which accelerates the aging process for contacting. This has in turn greatly limited the service life of previously available silicon carbide modules.

3300V CoolSiC™ silicon carbide trench MOSFET – The revolutionary energy-saving chip

After a large number of further developments in processing and chip design, a team led by Dr. Konrad Schraml, Dr. Caspar Leendertz (both Infineon) and Prof. Dr. Thomas Basler (Chemnitz University of Technology) has succeeded in readying the world's first 3300V voltage class silicon carbide MOSFET with vertical channel (trench MOSFET) for series production. The chip is characterized by extremely low conduction and switching loss levels and requires only a very small amount of the expensive semiconductor material. The team has also succeeded in integrating the necessary diode chip with the transistor and make it usable, leading to a drastic reduction in material consumption and enabling more efficient chip cooling.

Innovative copper contacting for the highest reliability

The team also took a novel approach to the topic of chip contact aging and developed an innovative copper technology which extends service life by a factor of 40 and thus more than compensates for the unfavorable material parameters of silicon carbide, equivalent to a ten-fold improvement compared to current silicon modules. In addition, the new contacting gives the module excellent robustness in accommodating current and voltage peaks, ensuring that the power converter can be safely and reliably shut down in case of a failure.

Saving energy at high energy flows

The new 3300V silicon carbide module has a nominal current of 1000 amperes and is the basis of a new generation of highly efficient power converters. These power converters save much electricity where ever large amounts of electricity are transmitted, for example when generating electricity in solar parks and wind parks, in power transmission, and more than anything in consumption. Compared to an existing silicon-based solution, a single locomotive with a silicon carbide drive system saves approximately 300 MWh per year, an amount equivalent to the annual consumption of 100 single-family homes. The low loss levels of the "train power converter" also make it possible to use air cooling instead of water cooling, meaning additional savings in operating expenses and system costs. The higher switching frequencies achieved also mean significant reductions in noise for these systems, so that trains, trams and other large drive applications are quieter and enjoy higher levels of public acceptance. In addition to rail technology, there are many other application areas for the innovative power semiconductor module, for example in energy management for large-scale battery storage systems or low-loss industrial production of green hydrogen.

High power density for electrification of large-scale drives

The greatest innovative leap is however the silicon carbide module's high power density and the power converters it makes possible. The new properties of the semiconductor module make these converters not only significantly more powerful, they also make them smaller and lighter by as much as 50%. In addition to the resulting cost savings, the high power density makes it possible to electrify large-scale drives which until now have had to operate on fossil fuels. Regardless of whether the energy source is a battery, a fuel cell or the power grid, the new 3300V power semiconductor module provides the right energy management in all cases. In the future this will make it possible to replace diesel-powered locomotives with battery-operated or hydrogen-powered trains and to drive agricultural and construction machinery electrically. Our customers are already in the process of evaluating the new module for use in the electrification of airplanes and ships as well.

Soon the new chip and contacting technology will also be used in smaller power classes. Then additional applications such as rapid charging for electric cars or the electrification of trucks can also benefit from reliable low-loss modules.

A new component for power converters creates new jobs in the industry

In addition to technological benefits, the community will also profit from the creation of many new jobs. The new module will be manufactured exclusively at the Warstein site in Germany's North Rhine-Westphalia. And a large number of companies in Germany are positioned in downstream value chains; they will then develop their own new, innovative power converter systems. The new module thus not only strengthens Infineon's competitive ability, it also generally strengthens Germany as a technology center.

Saving electricity at high energy flows and electrifying large drive systems: The benefits of the new 3300V CoolSiC™ XHP™2 high-performance module from Infineon in a nutshell. Many areas in public life will benefit from the use of these more energy-efficient and lower-emission technologies. They cut costs and help protect the environment. That's real power for the energy transformation.

About Infineon

Infineon Technologies AG is a global semiconductor leader in power systems and IoT. Infineon drives decarbonization and digitalization with its products and solutions. The company has around 58,600 employees worldwide and generated revenue of about €16.3 billion in the 2023 fiscal year (ending 30 September). Infineon is listed on the Frankfurt Stock Exchange (ticker symbol: IFX) and in the USA on the OTCQX International over-the-counter market (ticker symbol: IFNNY).

The right to nominate outstanding achievements for the Deutscher Zukunftspreis is incumbent on leading German institutions in science and industry as well as foundations.

The project "Power for the energy transition – Electrifying large-scale drives with revolutionary chips that save energy” was submitted by Deutsches Patent und Markenamt.

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache