Winner 2024

Digital light

Dr. Norwin von Malm and Stefan Groetsch from ams OSRAM teamed up with Dr.-Ing. Hermann Oppermann from the Fraunhofer Institute for Reliability and Microintegration IZM in Berlin to develop an all-new headlamp — a truly impressive demonstration of ingenuity! As Senior Director New Technologies at ams OSRAM, Dr. Norwin von Malm is responsible for front-end development, i.e. transferring new ideas and concepts from the scientific arena to the industrial environment. Stefan Groetsch leads the Hardware and Software Development team of the OS Mobility System Solution Engineering division. Dr.-Ing. Hermann Oppermann is a member of the Wafer-Level System Integration department of the Fraunhofer Institute IZM in Berlin, where he focuses on technologies for the manufacture of micro contacts, as well as on bonding technology and the assembly of fine-pitch components.

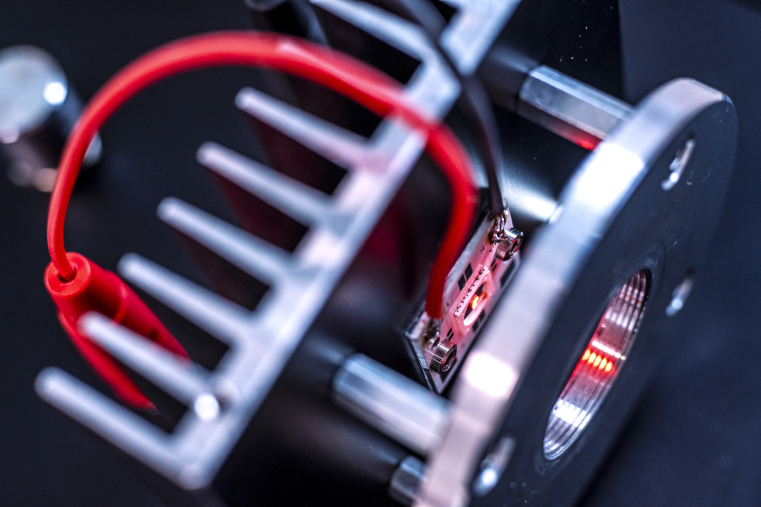

To master this huge challenge, it must be possible to control the spatial distribution of light in order to optimally adapt the light to any upcoming situation. Since this cannot be realized with a simple low/high beam combination, the new light source doesn't feature just two, but even 25,600 LEDs in a matrix consisting of 320 x 80 light points. Each individual LED can be controlled by a digital signal. In combination with an optics device, a headlamp is created that works similar to a video projector.

Areas requiring bright light are precisely illuminated, whereas other areas, such as an oncoming vehicle, remain in the dark to avoid blinding other road users. The driver benefits from a complete high beam on extra-urban roads without compromising the view of others. This provides additional safety.

What’s new and special about this system is that it requires minimal installation space while also operating highly efficiently. Only those LEDs actually required to achieve the light distribution desired are switched on. Other systems with passive light modulation operate on the basis of shadowing. This means that a primary light source constantly operates at full power while filtering out undesired light. This principle has, however, disadvantages: first, it isn’t efficient to create light and eliminate it at the same time; secondly, the power loss caused in the process must be dissipated, which, in turn, requires large, cost-intensive cooling systems. In contrast, with the new system, such losses do not occur at all because only those LEDs in the matrix that are actually required are switched on.

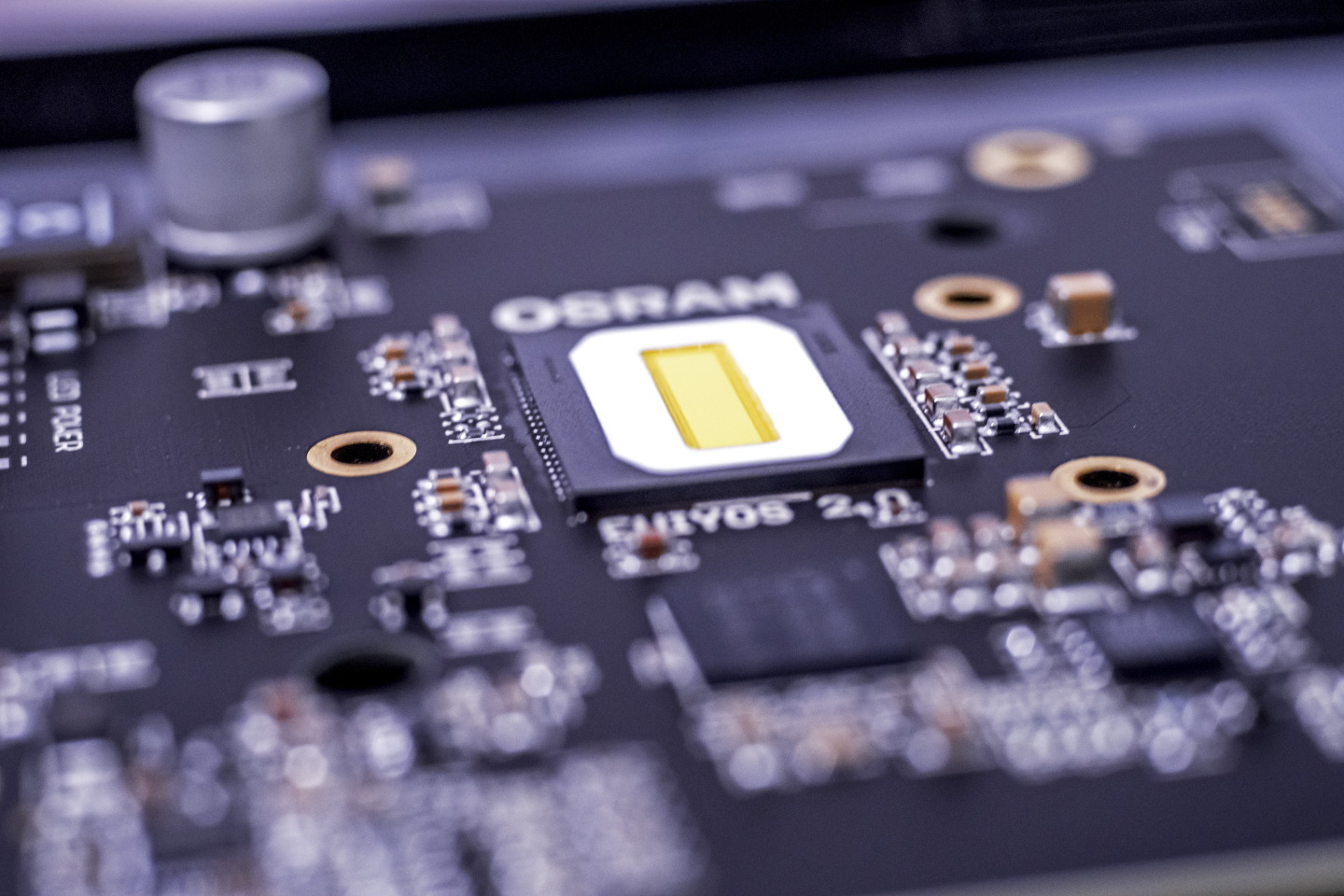

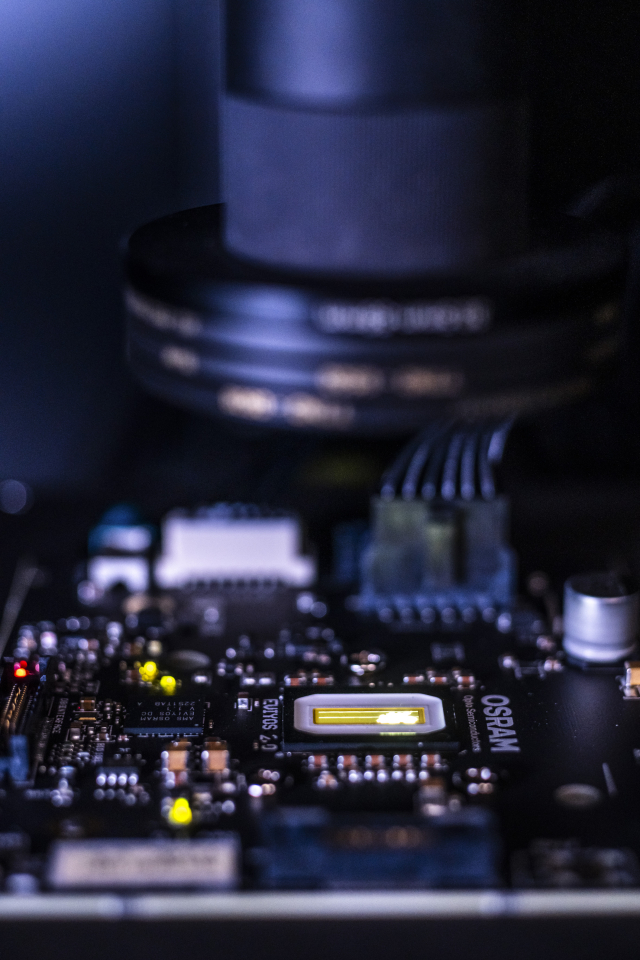

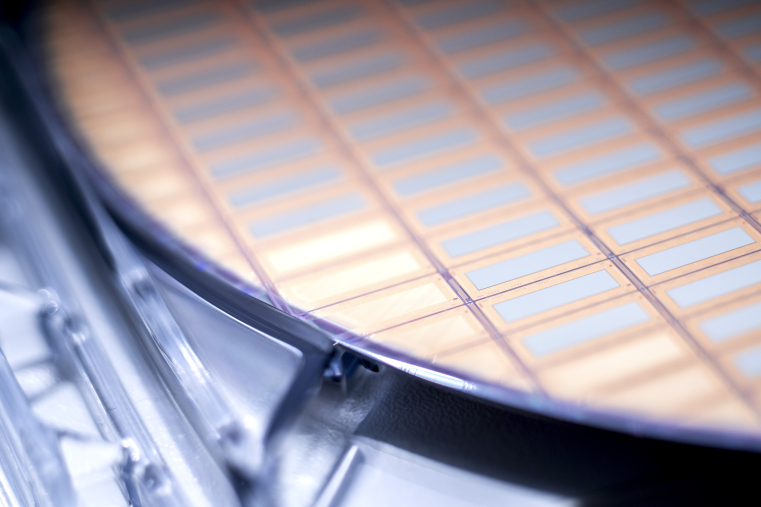

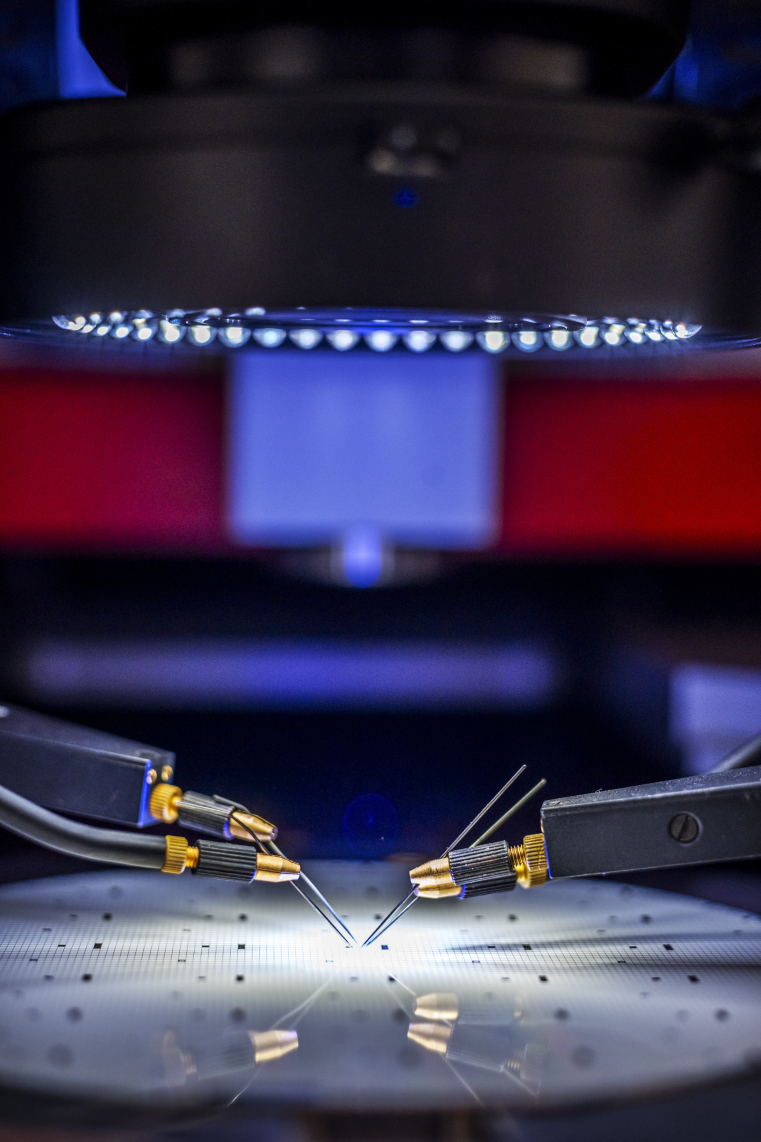

However, building such an LED matrix poses several challenges: a large LED must be subdivided into a matrix of many tiny LED pixels. Furthermore, each LED on the matrix must be contacted individually to be able to switch them on and off separately. To achieve this, another matrix, featuring an electronic circuit required for this purpose, is positioned precisely under the LED matrix and then connected to the LED matrix with a precision down to one pixel. Since the light-emitting semiconductor and the semiconductor of the electronic circuit display greatly differing properties, special bonding layers and processes had to be developed for this purpose.

More Details

Resume

Dr. Norwin von Malm

06.10.1972

Born in Koblenz

1994 - 2000

Graduate Studies of Chemistry at Julius-Maximilians-Universität Würzburg

2000 - 2003

PhD at Technische Universität Darmstadt, program Materials Sciences

2003 - 2005

Development Engineer thermal processes at OSRAM Opto Semiconductors

2005 - 2008

Development Engineer OLED at OSRAM Opto Semiconductors

2008 - 2010

Development Engineer Advanced Concepts and Engineering, LED Chipdesign at OSRAM Opto Semiconductors

2010 - 2016

Senior Manager Advanced Concepts and Engineering, Materials and Processes at OSRAM Opto Semiconductors

2016 - 2018

Director Backend Material Innovation at OSRAM Opto Semiconductors

Since 2019

Director New Technologies at ams OSRAM International

Since 2024

Senior Director New Technologies

Patents

Inventor of 91 granted patent families, further 63 pending patent applications

Publications

15 peer-reviewed journal articles and conference proceedings, thereof eight as first or last author Presentations on international conferences

Stefan Grötsch

10. 09. 1971

Born in Sulzbach-Rosenberg

1990 - 1994

Studies of Microsystems Technology at OTH Regensburg

1995 - 2002

R&D Engineer High Power Laser Diodes

Siemens AG Semiconductors, then OSRAM Opto Semiconductors GmbH2002 - 2010

Senior/Principal Engineer LED Product development

OSTAR Platform/ LED Projection OSRAM Opto Semiconductors GmbH2011 - 2022

Principal Engineer Automotive Application Engineering

OSRAM Opto Semiconductors GmbH, now ams-OSRAM International GmbHSeit 2012

Principal Key Expert und Owner of Technology Field Application OSRAM Opto Semiconductors GmbH, now ams-OSRAM International GmbH

2013 - 2016

FMER-Project coordinator µAFS at OSRAM Opto Semiconductors GmbH

2018 - 2022

System Architect EVIYOS 2.0 Multipixel-LED light source OSRAM Opto Semiconductors GmbH, now ams-OSRAM International GmbH

Since 2022

Director Hard- und Software in automotive System Solution Engineering ams-OSRAM International GmbH

Patents

inventor of 94 granted patent families and a further 35 pending patent applications

Publications

14 Publications in the context of Digital Light

Honors and Awards

1993

Study Abroad Scholarship from Carl Duisberg Gesellschaft

1997

Siemens Innovation Award for the 5W Laser Diode

2006

Science Award of Stifterverband for the German Science

2011

OSRAM Orange Award for ceramic light conversion technology

Dr.-Ing. Hans-Hermann Oppermann

08.07.1958

Born in Oschersleben

1978 – 1986

Studied materials science and materials engineering at Technische Universität Clausthal with a focus on metallic materials

1986

Graduated engineer (Diplom-Ingenieur) in the field of metallurgy with a focus on materials science – metallic materials at Technische Universität Clausthal

1986 – 1992

Research assistant with teaching position at the Institute for Metal Research, Chair of Metal Physics at Technische Universität Berlin

1992

Passed his doctorate in engineering (Dr.-Ing.) at the Technische Universität Berlin in the field of materials science with distinction.

1993 – 1998

Research associate at the Forschungsschwerpunkt “Technologien der Mikroperipherik” at the Technische Universität Berlin

Since 1998

Research associate at the Fraunhofer Institute for Reliability and Microintegration (IZM)

1998 – 2008

Group manager Optoelectronics, RF and Sensor Integration at Fraunhofer IZM Berlin

2008 – 2021

Group manager Interconnect Metallurgy and Processes at Fraunhofer IZM Berlin

Since 2021

Group manager Fine Pitch Assembly and Interconnects at Fraunhofer IZM Berlin

Research Fellowship

1998 – 1999

Assistant Professor at Microsystem Integration & Packaging Lab in the University of Tokyo

Honors and Awards

2004

IZM Research Prize for outstanding research achievements in the field of microelectronics, microsystems technology and packaging: “Development of chip connection technologies based on gold-tin solder for high-frequency and optoelectronic applications”

Granted Patents

54 granted patent families, of which 23 are active.

Publications

Approximately 200 publications, 55 of which as first author.

Contact

Press

Volker Gieritz

Group Press Spokesperson

Corporate Communications

ams OSRAM Group

OSRAM GmbH

Marcel-Breuer-Str. 4

80807 München

Phone: +49 (0) 89 / 62 13 35 83

Mobile: +49 (0) 171 / 31 59 411

E-Mail: Volker.Gieritz@ams-osram.com

Web: ams-osram.com

A description provided by the institutes and companies regarding their nominated projects

Digital light – intelligent LED technology for tomorrow's world

A technological breakthrough often does not originate from a scientific or technological discovery, but is rather the product of a vision: an idea for the future. For a team of specialized ams OSRAM engineers, the initial spark already ignited during a conversation with a customer at the beginning of the 2010s. Their groundbreaking idea? A pixelated LED light source!

Until that time, an LED was just a simple chip creating a homogeneous light beam, i.e. a single point source. In contrast, the new digital light technology is based on a matrix of hundreds or even thousands of tiny light points (pixels). Each of them is controlled by a digital data stream that continuously reconfigures the light output of the matrix, and thus the light distribution in a space: millisecond by millisecond. This futuristic idea had the potential to fundamentally transform the concept of light.

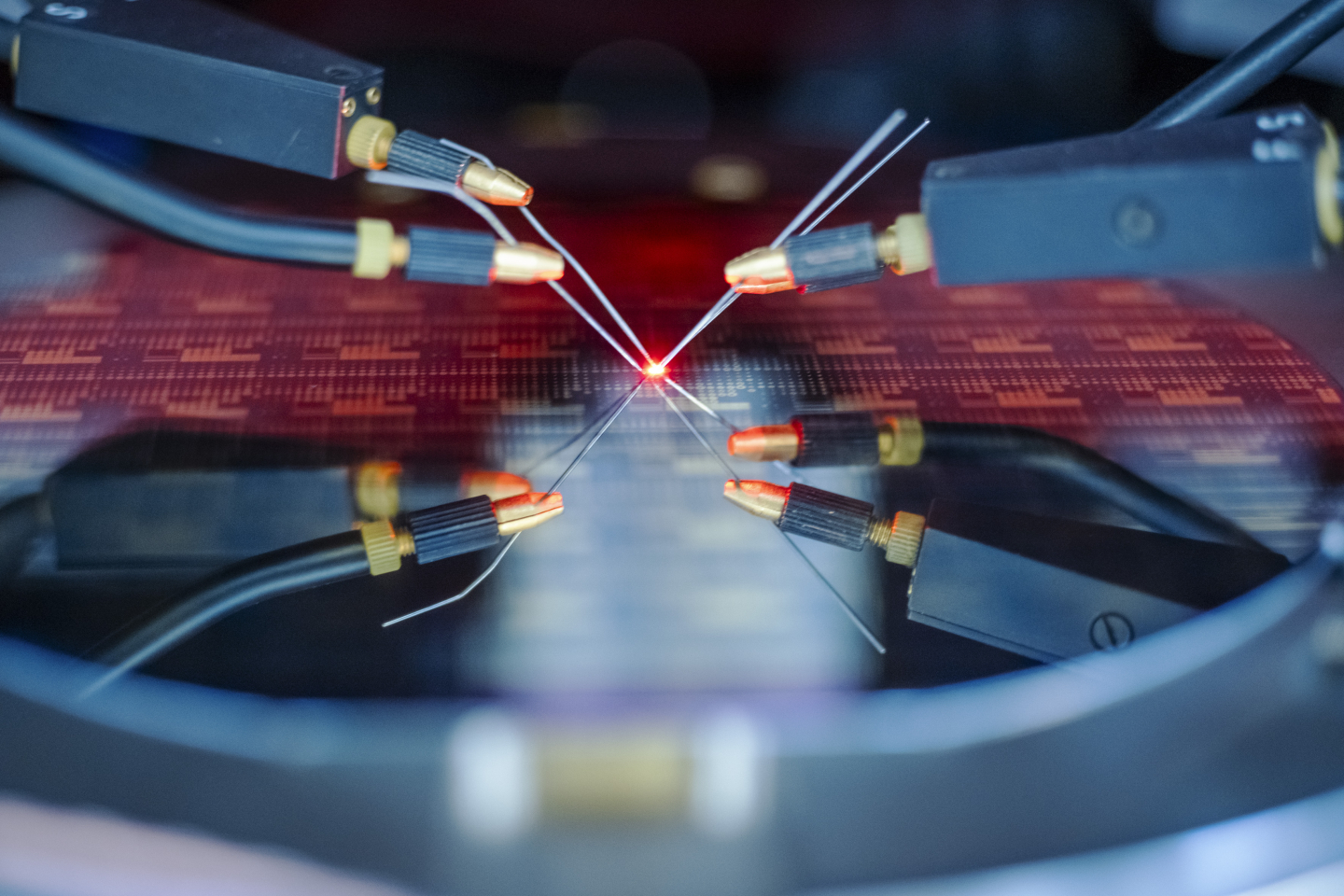

However, a whole series of fundamental breakthroughs in basic physics, semiconductor manufacturing and materials science had to happen to finally be able to divide the light-emitting semiconductor into tiny pixels — and connect each of these pixels to a microscopic trigger circuit. In addition, a new chip architecture and a so-called pixel-level bonding technology had to be developed to establish a connection between each LED pixel and its integrated driver in a single, integrated component.

In close cooperation with Dr.-Ing. Hermann Oppermann from the Fraunhofer Institute for Reliability and Microintegration IZM in Berlin, Dr. Norwin von Malm and Stefan Grötsch from ams OSRAM and their teams successfully developed an all-new headlamp on the basis of this pixelated light source. With their “digital light”, they thus established a technology that will enable numerous additional intelligent applications.

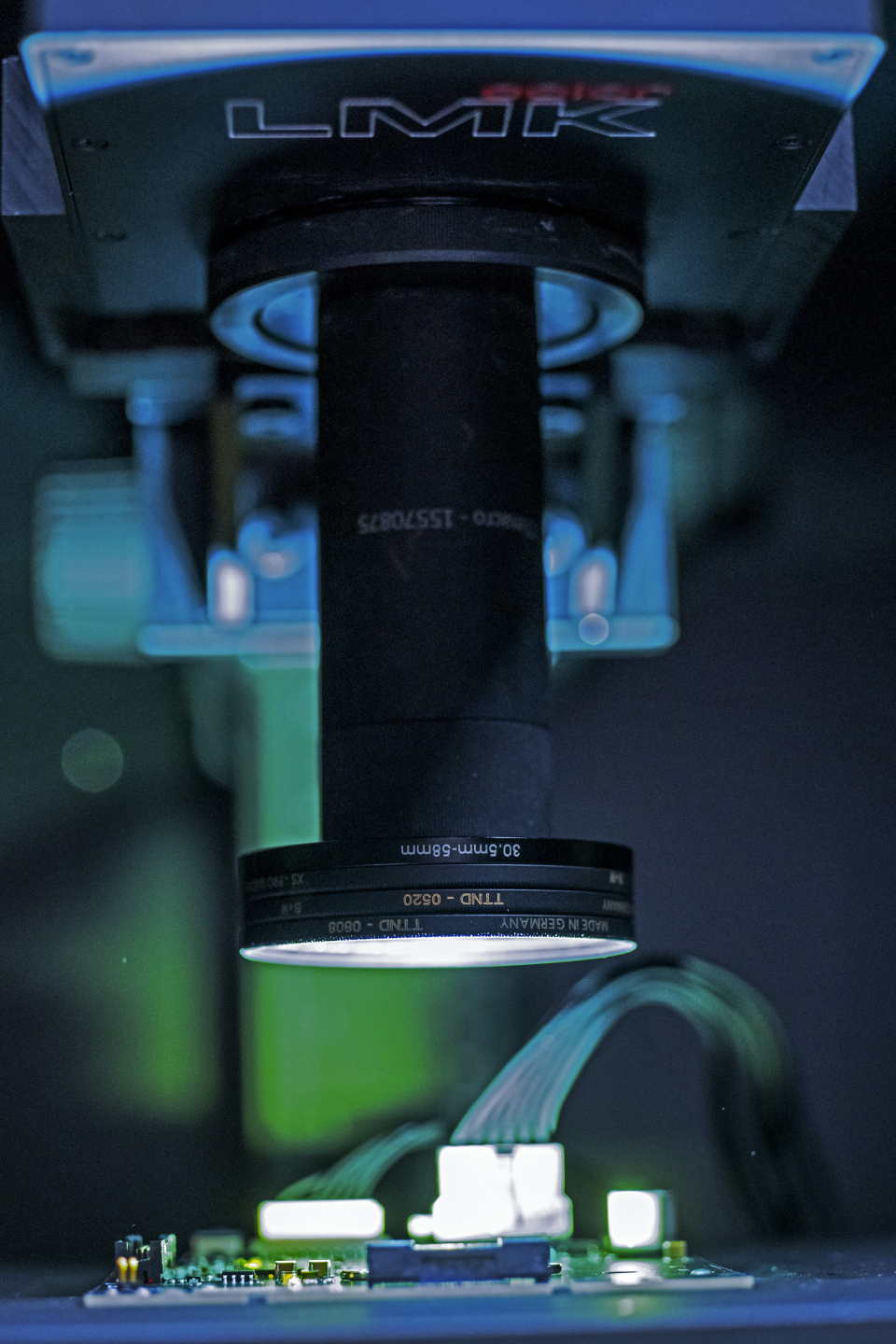

The EVIYOS® LED is an innovative multi-pixel light source for automotive headlamps. Thanks to the chip's 25,600 individually controllable LEDs with a pixel pitch of 40 µm, the EVIYOS 2.0 can selectively illuminate the road ahead, maximizing the driver’s view in high-beam mode without compromising that of other road users. The deployment of this intelligent LED technology considerably improves road safety, giving drivers more time to respond to dangers that can only be partially recognized with conventional headlamps, or even not at all. Furthermore, this optimized view promises to transform the driver’s experience of the road ahead at night, making night driving safer and easier.

Until now, numerous automotive features were designed to keep the driver and passengers inside the vehicle safe. With images consisting of a large number of LED pixels projected on the road at night, the vehicle can communicate in new ways to both the driver and other road users in its surroundings. To mention just one example: headlights based on EVIYOS 2.0 can project a snowflake symbol onto the road to warn of icy or slippery conditions, raise awareness of danger and hence reduce the risk of accidents.

But the possibilities of digital light go even far beyond illumination: the extremely tiny LED pixels can also be embedded into a transparent display screen while still producing a sharp, clear image. First potential applications of this transparent display capability could be in the rear windows of automobiles. Here, the intelligent LED technology could display signals and warnings to the vehicle behind.

Serving as miniaturized projectors, the pixelated LED chips of “digital light” will also be a key element of next-generation Augmented and Virtual Reality (AR/VR) devices. In addition to displaying information, this intelligent LED technology for tomorrow’s world promises to enhance the efficiency of high-bandwidth optical communication in optical data processing: the laser light sources still in use today switch at very high frequency to transmit serial data streams via a fiber optic cable (FOC). In the future, however, “digital light” will pave the way toward parallel data transmission at much higher bandwidths, contributing to reducing the energy footprint of energy-hungry data centers.

In a nutshell: Norwin von Malm, Stefan Grötsch, Hermann Oppermann and their teams have successfully developed a basic technology whose success story began with the breakthrough in automotive lighting. But digital light even has the potential to revolutionize the interface between people and electronics.

About ams OSRAM

The ams OSRAM Group (SIX: AMS) is a global leader in intelligent sensors and emitters. By adding intelligence to light and passion to innovation, we enrich people's lives.

With over 110 years of combined history, our core is defined by imagination, deep engineering expertise and the ability to provide global industrial capacity in sensor and light technologies. We create exciting innovations that enable our customers in the automotive, industrial, medical and consumer markets to maintain their competitive edge. We thereby drive innovation that sustainably improves the quality of life in terms of health, safety and convenience, while reducing impact on the environment.

Our around 20,000 employees worldwide focus on innovation across sensing, illumination and visualization to make journeys safer, medical diagnosis more accurate and daily moments in communication a richer experience. Our work creates technology for breakthrough applications, which is reflected in over 15,000 patents granted and filed. Headquartered in Premstaetten/Graz (Austria) with a co-headquarters in Munich (Germany), the group achieved EUR 3.6 billion revenues in 2023 and is listed as ams-OSRAM AG on the SIX Swiss Exchange (ISIN: AT0000A18XM4).

Find out more about us at https://ams-osram.com

The right to nominate outstanding achievements for the Deutscher Zukunftspreis is incumbent on leading German institutions in science and industry as well as foundations.

The project "Digital light — intelligent LED technology for tomorrow's world” was submitted by Fraunhofer Institute.

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache