Nominee 2019

CO2

Dr. rer. nat. Christoph Gürtler, Prof. Dr. rer. nat. Walter Leitner and Dr. rer. nat. Berit Stange have proven that it is possible to join the loop - and that the use of the greenhouse gas CO2 has marketable options. The nominees have developed a chemical process based on a custom catalyst which utilizes inert carbon dioxide to produce polyols - a component of plastics used in a variety of different applications.

Christoph Gürtler heads the New Processes and Products Division at Covestro Deutschland AG in Leverkusen, Walter Leitner is chair of “Technical Chemistry and Petrochemistry” at RWTH Aachen University and is also Director at the Max Planck Institute for Chemical Energy Conversion in Mülheim an der Ruhr. Berit Stange is head of Circular Economy Polyurethanes at Covestro Deutschland AG.

More Details

Resume

Dr. rer. nat. Christoph Gürtler

- 3.10.1967

- Born in Casablanca, Morocco

- 1987 - 1992

- Student of Chemistry, University of Bonn and Technical University of Berlin, Germany

- 1993

- Graduation in Chemistry, University of Bonn

- 1993 - 1996

- PhD student of Organic Chemistry, Technical University of Berlin

- 1996 - 1997

- Postdoctoral researcher, Massachusetts Institute of Technology (MIT), Department of Chemistry, Cambridge/USA

- 1997 - 1999

- Head of Laboratory and Project Manager, Central Research Department, Bayer AG

- 1999 - 2005

- Head of Laboratory and Project Leader, Coating Raw Materials Department: Production of new, environmentally compatible polyurethane systems for coatings, elastomers and catalysts for polyurethane systems, Bayer MaterialScience AG, Leverkusen

- 2006 - 2007

- Strategic consultant to the Executive Board for Innovation and Marketing, Bayer MaterialScience AG

- 2007 - 2015

- Head of Department for Catalysis and Sustainable Chemistry in Polyurethanes Process Research: Development of polymers, including those based on CO2 as a raw material, Bayer MaterialScience AG

- 2015

- Restructuring of the Chemical Catalysis and Process Research in the Polyurethane Innovation Division, Covestro Deutschland AG, Leverkusen

- Since 2018

- Head of Catalysis and Technology Incubation: Product & Process development, incl. up-scaling and market launch, Covestro Deutschland AG

ther activities and honorary posts

- 1999 - 2005

- Supervisor of cooperations with Russian universities and research institutions (Russian Academy of Science)

- 2007

- Founder of the CAT Catalytic Center, a Research Centre for new Catalytic Chemical Processes, jointly with RWTH Aachen University

- 2007 - 2015

- Cooperation with funding organisations (BMBF, EU) and committee work (Dechema, Cefic)

- Since 2012

- Invited Lecturer, Lecture Series "Sustainable Industrial Chemistry", RWTH Aachen University

- Since 2017

- Initiator and leader of Carbon4PUR (project on the use of CO2/CO, funded under Horizon 2020)

- Since 2017

- Member of the Board of the VAA (Chemistry Managers) e.V.

- Since 2018

- Member of the Advisory Board of the Nova Institute for CO2 Use Issues

- Since 2018

- Member of the Advisory Board of the Global CO2 Initiative

- 2019

- Co-Chairman of the International Conference for CO2 Utilization, Aachen

Patents, Publications and Presentations

- Author / co-author of more than 142 patents and patent applications, including 48 on CO2 use

- 2007

- Invited Lecture, Gordon Research Conference for Coatings, New London

- 2014

- Invited Lecture, GdCH Interdisciplinary Symposium, Darmstadt

- 2015

- Invited Lecture, ACS Industrial Chemistry Symposium, Denver

- 2015

- Invited Lecture, Macromolecular Colloquium, Freiburg

- 2016

- Invited Lecture, ICCDU, Sheffield

- 2016

- Invited Lecture, Gordon Research Conference for Green Chemistry, Snowflake

- 2018

- Invited Lecture, ProcessNET, Aachen

- 2018

- Invited Lecture, ICCDU, Rio de Janeiro

- 2018

- Invited Lecture, National Science Foundation, Washington D.C.

- 2018

- Invited Lecture, European Petrochemical Association, Vienna

- Involved in numerous EU studies and papers, including the AcaTech CO2 usage study

Honours and Awards

- 2014

- Laureate of the Otto-Bayer-Medaille, Bayer AG

Prof. Dr. rer. nat. Walter Leitner

- 1.2.1963

- Born in Pfarrkirchen, Germany

- 1982 - 1987

- Student of Chemistry, University of Regensburg (Dipl.-Chem. Univ.)

- 1987 - 1989

- PhD (Dr. rer. nat.) with Prof. H. Brunner, Institute for Inorganic Chemistry, University of Regensburg

- 1990

- Postdoctoral student with Prof. J. M. Brown, Dyson Perrins Laboratory for Organic Chemistry, University of Oxford, UK

- 1991 - 1992

- Liebig Fellow of the Fonds der Chemischen Industrie, Institute for Inorganic Chemistry, University of Regensburg

- 1992 - 1995

- Research associate at the Max-Planck-Working Group „CO2-Chemistry“ (Director: Prof. E. Dinjus), Friedrich-Schiller-University Jena

- 1995

- Habilitation (Dr. rer. nat. habil.) in Inorganic Chemistry and appointment as Lecturer (Privatdozent), Friedrich-Schiller-University Jena

- 1995 - 1998

- Group leader at the Department of Organic Synthesis (Director: Prof. M. T. Reetz), Max-Planck-Institut für Kohlenforschung, Mülheim/Ruhr

- 1998 - 2002

- Head of the Technical Laboratories, Max-Planck-Institut für Kohlenforschung, Mülheim/Ruhr

- Since 2002

- Chair of Technical Chemistry and Petrochemistry, Institute for Technical and Macromolecular Chemistry, RWTH Aachen University

- 2002 - 2017

- External Scientific Member of the Max-Planck-Institut für Kohlenforschung, Mülheim/Ruhr

- Since 2007

- Academic Director of CAT, the joint Catalytic Center of RWTH Aachen University and Covestro

- Since 2017

- Director for Molecular Catalysis, Max-Planck Institute for Chemical Energy Conversion (MPI CEC), Mülheim/Ruhr

Other activities and honorary posts

- Since 2014

- Member of the Scientific Advisory Board of the Renewable Energy Program of the Karlsruhe Institute of Technology KIT

- Since 2015

- Member of the Scientific Council of the German Scientific Society of Oil, Gas and Coal, DGMK

- Since 2016

- Chairman of the Coordination Group of the Kopernikus Project P2X: Exploration, Validation and Implementation of „Power-to-X“ Concepts

- Since 2018

- Member of the Editorial Board of the scientific journal on applied chemistry “Angewandte Chemie”

- Since 2018

- Member of the Board of the German Society for Chemical Engineering and Biotechnology, DECHEMA

- Since 2019

- Co-Speaker of the Cluster of Excellence “The Fuel Science Center”, RWTH Aachen University/MPI CEC

- 2019

- Chairman of the 14th EuropaCat international conference

- 2019

- Chairman of the International Conference on Carbon Dioxide Utilization ICCDU XVII

- 2019/2020

- Chairman of the Gordon Conference on “Green Chemistry

Publications, Presentations and Patents

- Over 300 contributions to peer-reviewed international journals and edited monographs, with a total number of >13 000 citations and h-index of 61 (web of science; June 2019)

Co-Editor of the books Chemical Synthesis Using Supercritical Fluids (Wiley/VCH1999), Multiphase Homogeneous Catalysis (Wiley/VCH 2005) and Handbook of Green Chemistry, Vol 4-6: Green Solvents (Wiley/VCH, 2010)

More than 60 patents and patent applications

More than 100 invited lectures at international conferences and research institutions

Honours and Awards

- 1997

- Gerhard-Hess Award of the German Science Foundation (Deutsche Forschungsgemeinschaft (DFG))

- 1998

- Bennigsen Funding Award of North Rhine-Westphalia (NRW)

- 1998

- Carl-Zerbe Award of the Deutsche Wissenschaftliche Gesellschaft für Erdöl, Erdgas und Kohle (DMGK)

- 2000

- 2nd International Messer Innovation Award

- 2001

- Otto-Roelen-Medal of DECHEMA

- 2003

- Griess Lectureship of the Royal Society of Chemistry (RSC)

- 2005

- Guest Professorship at the Universitè de Bourgogne, Dijon, France

- 2008

- CATSA Eminent Visitor Award of the South African Catalysis Society

- 2009

- Wöhler Award of the Gesellschaft Deutscher Chemiker (GDCh)

- 2010

- Fellow of the Royal Society of Chemistry (FRSC)

- 2011

- Honorary Member of the Chemical Society of Ethiopia

- 2013

- Visiting Lecturer for Promotion of Chemistry, National Science Foundation, Taiwan

- 2014

- European Sustainable Chemistry Award of the European Science Association of Chemical and Molecular Sciences (EuCheMS), jointly with Prof. Jürgen Klankermayer (RWTH Aachen University)

- 2015

- Nankai University Lectureship in Organic Chemistry, Nankai University, China

- 2015

- Molecular Science Forum Lecture of Chinese Academy of Sciences and Chinese Chemical Society

- 2018

- Casey Lecture of the University of Wisconsin, Madison, USA

- 2018

- Evonik Lecture at the Biennial Meeting of the Chinese Chemical Society, Hangzhou, China

Dr. rer. nat. Berit Stange

- 19.05.1976

- Born in Schwäbisch-Hall, Germany

- 1996 - 2002

- Student of Chemistry, Institute of Physical, Nuclear and Macromolecular Chemistry, Philipps-University Marburg

- 2002 - 2005

- PhD student, Institute of Physical, Nuclear and Macromolecular Chemistry, Philipps-University Marburg

- 2005 - 2009

- Laboratory Manager, Business Unit Polycarbonates, Bayer MaterialScience AG, Leverkusen, Germany

- 2009 - 2012

- Technical Market Segment Developer for „Electricity and Illumination”, Business Unit Polycarbonates, Bayer MaterialScience AG,

- 2012 - 2014

- Key Account Manager, Business Unit Polycarbonates, Bayer MaterialScience AG

- 2014 - 2015

- Assistant to the Head of Business Unit Polyurethanes, Bayer MaterialScience AG

- 2015 - 2016

- Assistant to the Board Member for Innovation and Head of Business Unit Polyurethanes, Covestro AG, Leverkusen, Germany

- 2016 - 2018

- Project Manager cardyon®, Business Unit Polyurethanes, Covestro Deutschland AG

- Since 2018

- Head of “Circular Economy Polyurethanes”, Business Unit Polyurethanes, Covestro Deutschland AG

Other activities and honorary posts

- 2002 - 2005

- Researcher, Institute of Physical, Nuclear and Macromolecular Chemistry, Philipps-University Marburg

- 2005 - 2009

- Researcher and developer of new flame retardant systems for different polycarbonate applications, Bayer MaterialScience AG

- 2009 - 2012

- Market Segment strategist for Europe, Bayer MaterialScience AG

- 2012 - 2014

- Development and Implementation of the Key Account Strategy for Medical Accounts, Bayer MaterialScience AG

- 2017 - 2018

- Responsible for global market launch of the new CO2 technology and the new product cardyon®, Covestro Deutschland AG

Publications and Patents

- Author and co-author of more than 20 patents and patent applications

Contact

Press

Dr. Grzegorz Darlinski

Alliance Management

Covestro Deutschland AG

51365 Leverkusen

Phone: +49 (0) 214 / 60 09 75 68

Mobil: +49 (0) 174 / 16 25 184

E-Mail: grzegorz.darlinski@covestro.com

Spokesperson

Dr. Christoph Gürtler

Covestro Deutschland AG

51365 Leverkusen

Phone: +49 (0) 214 / 60 09 21 77

E-Mail: christoph.guertler@covestro.com

A description provided by the institutes and companies regarding their nominated projects

Modern society releases huge amounts of carbon dioxide (CO2) that accumulate in the atmosphere, but the greenhouse gas also contains something useful: carbon, a central building block for products in the chemical industry. Thanks to a new process, CO2 can now be used as a raw material for high-quality materials and can partially replace crude oil in their production. This is a contribution to the conservation of resources and the promotion of circularity, thanks to the expertise, perseverance and ingenuity of experts at RWTH Aachen University, the Max Planck Institute for Chemical Energy Conversion and the materials manufacturer Covestro.

Summary

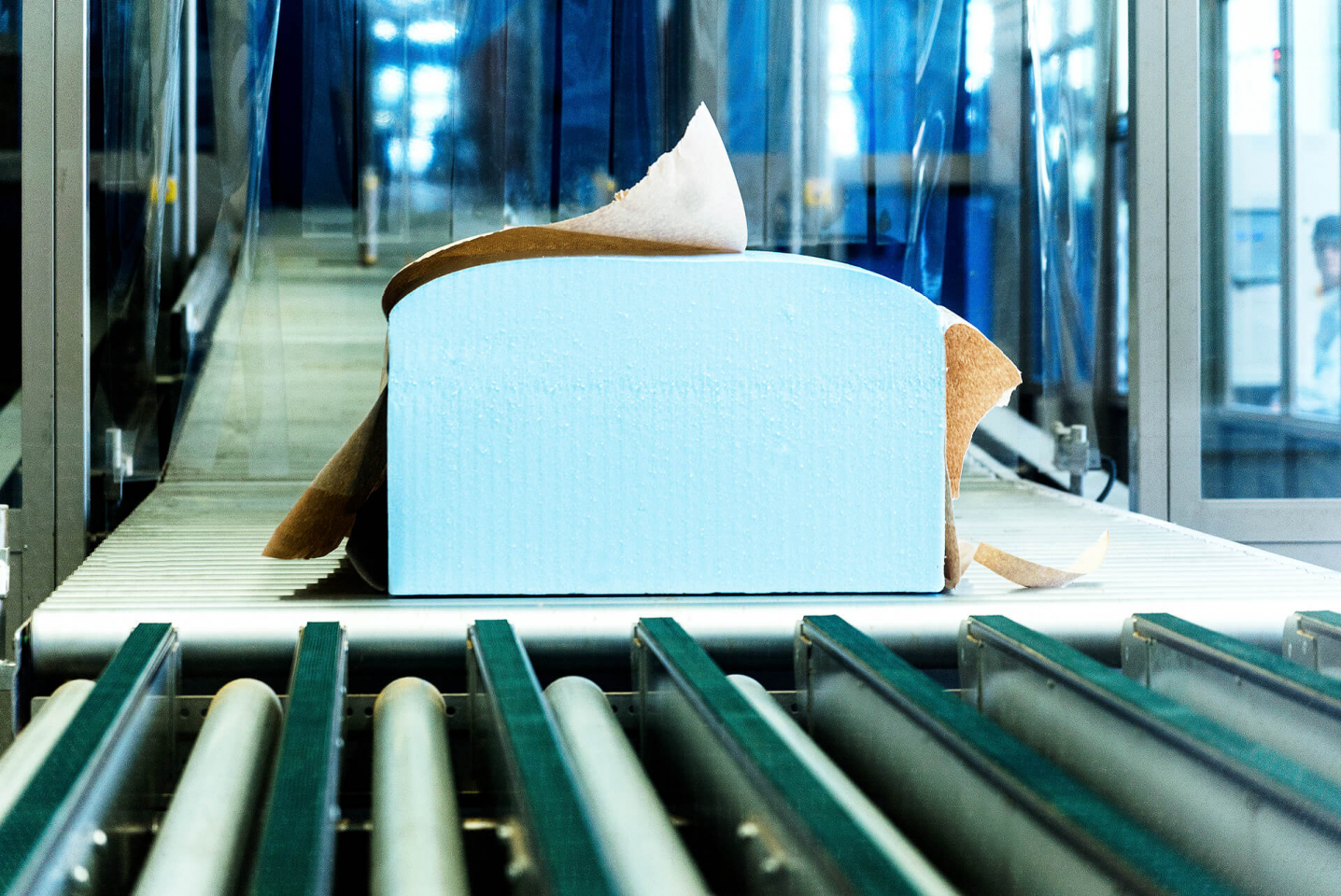

Industrially usable CO2-based polyols are the result of application-oriented fundamental research within the framework of the CAT Catalytic Center, a scientific facility jointly operated by Covestro and RWTH Aachen University along with research and development work at Covestro. Polyols are used to make polyurethanes that have applications in mattresses, insulation materials, and many other everyday products. The use of CO2 as a raw material improves the overall environmental balance of the polyols’ production process.

The team

Nominated for the German Future Prize are Prof. Dr. Walter Leitner, Chair of Technical Chemistry and Petrochemistry at RWTH Aachen University and Director at the Max Planck Institute for Chemical Energy Conversion in Mülheim an der Ruhr; Dr. Christoph Gürtler, Head of New Processes and Products at Covestro; and Dr. Berit Stange, Head of the Polyurethanes Circular Economy Division, also at Covestro.

The idea

It seems an obvious concept: if mankind produces vast amounts of CO2, which acts as a greenhouse gas harmful to the climate, why not try to use it, at least in part, as a raw material for the chemical industry? This would reduce its dependence on fossil resources such as crude oil and be a step towards closed carbon cycles in chemical production.

The challenge

The idea was first formulated in the late 1960s, but there was a considerable obstacle to its implementation: the high amount of energy required to activate inert CO2, which undermined its economic and ecological benefits.

The solution

Despite the challenges, the nominees for the German Future Prize have succeeded in developing a new catalytic process by which CO2 is incorporated in well-controlled quantities into polymer materials, specifically polyurethanes that serve a wide range of applications.

The new product can be integrated into existing production processes in the industrial value chain. It is an innovation that moved from the laboratory to industrial use in a short space of time. Since 2016, Covestro has been using this novel process to produce a central component of polyurethanes on an industrial scale in a newly built plant at its Dormagen site in Germany. At the same time, the process is being evaluated for an even larger industrial production.

The product

CO2 is used to manufacture polyols marketed under the cardyon® brand name. Up to 20 percent of the conventional raw material propylene oxide, which is obtained from crude oil, can be replaced. The first final products are already available. For example, Recticel is a pioneer company in offering foams for mattresses containing cardyon® and Polytan uses binders with CO2-based polyols in the elastic layer of sports floor systems.

The benefits

Using CO2 as a recyclable material conserves fossil carbon sources. At the same time, the technology reduces the total energy requirement across the polyols' value chain, which not only reduces CO2 emissions from the chemical industry at this point, but also facilitates marketable solutions. The CO2 is permanently bound in the material and can also positively contribute to the material properties in many applications. The new process not only makes production more environmentally friendly, but also has economic attractions.

The perspective

The current applications illustrate the potential of innovation in a market with an annual product volume of several million tons. As a platform technology designed, the new process is also able to provide feedstocks for elastic textile fibers containing CO2, which are currently still in the testing stage. As further examples, surface-active substances such as those used in detergents can also be produced with CO2 as a raw material.

In addition, the project has an impact beyond the actual application. Motivated by the success story of CO2-based polyols, research at RWTH Aachen University, the Max Planck Institute for Chemical Energy Conversion, and Covestro AG also aims to utilize CO2 in other future production processes which previously used only fossil raw materials. The collaboration exemplifies how today's complex challenges such as climate change, which requires turning away from fossil raw materials at an increasing rate, can be tackled successfully through close cooperation between science and industry. Projects such as this nominated innovation contribute to safeguarding Germany as a business location while at the same time taking into account industry’s ecological and social responsibility.

Covestro Deutschland AG

Covestro is one of the world's leading manufacturers of high-quality chemical-based materials. The company's products and applied solutions form the basis for important industries and are found in many areas of modern life. The focus is placed on innovative, sustainable solutions for the major challenges of our time – such as climate change, scarcity of resources, increasing mobility and urbanization. Covestro employs around 16,800 people worldwide and generated sales of 14.6 billion euros in 2018.

RWTH Aachen University

With its 260 institutes in nine faculties, RWTH Aachen University, as a "University of Excellence”, is one of Europe's leading scientific institutions. In the winter semester of 2018/2019, more than 45,000 students were enrolled, almost a quarter of them international students from more than 125 countries. Researchers with expertise in basic research and highly specialized applications work together in interdisciplinary profile areas to develop sustainable solutions and turn ideas into innovations. The financial volume of the RWTH amounts to almost one billion euros, of which more than 385 million euros are third-party funds.

MPI for Chemical Energy Conversion

Research at the Max Planck Institute for Chemical Energy Conversion (MPI CEC) in Mülheim an der Ruhr aims to understand the basic chemical processes that play a key role in the conversion of electrical energy into chemical compounds for energy storage and chemical value creation, e.g. based on CO2. Aiming to turn global energy systems around and replace finite fossil fuels with renewable resources, it is essential to link energy generation and chemical production in a sustainable, environmentally friendly and cost-effective way. To this end, the 280 employees at the MPI CEC, including young scientists from over 30 nations, are creating the scientific basis for technology options that expand the political and social scope for action.

The right to nominate outstanding achievements for the Deutscher Zukunftspreis is incumbent on leading German institutions in science and industry as well as foundations.

The project " CO2 – a raw material for sustainable plastics" was submitted by acatech - the National Academy of Science and Engineering, the German Rectors' Conference HRK and the Max Planck Society for the Advancement of Science.

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache