Nominee 2018

Eine radikal neue Getriebegattung

Dipl.-Ing. (FH) Thomas Bayer and Dr.-Ing. E.h. Manfred Wittenstein have answered this question with a technical sensation. Both engineers were not satisfied with a modest correction or improvement. Instead of concentrating on the finer points of gearbox mechanics, they went to the very root of the challenge: the nominated innovators invented a completely new type of gearbox that is a radical departure from the conventional variants. They achieved a definite improvement in all performance characteristics, in some cases exponentially - and used much less energy and material. Thomas Bayer is head of the company's Innovation Lab, Manfred Wittenstein is Chairman of the Supervisory Board at Wittenstein SE in the city of Ingersheim in the federal state of Baden-Württemberg.

Whether in machine tools, milling heads or welding robots: gearboxes are found in many technical devices. They are the veritable heart of the machines. Countless manufacturing steps in industrial production would be impossible without them. The result: because they are so commonly used, technical progress in gearbox design has a direct and global impact on production costs and energy consumption. Until recently, the further development of gearboxes has progressed at a snail's pace, taking the form of changes in individual technical parameters.

more details

Resumes

Dipl.-Ing. (FH) Thomas Bayer

Dipl.-Ing. (FH) Thomas Bayer

- June 18, 1960

- Born in Johannesberg

- 1975 - 1978

- Apprenticeship as a toolmaker with Ultra Präzisionswerk, Aschaffenburg, Germany

- 1980

- Abitur (university entrance qualification) at Hanau Technical College, Germany

- 1980 - 1981

- Compulsory military service

- 1981 - 1985

- Degree course in Mechanical Engineering, majoring in Design, at Würzburg-Schweinfurt University of Applied Sciences

- 1985 - 1988

- Design engineer at KUKA Systems GmbH, Augsburg, Germany

- 1989 - 1993

- Development and computational engineer at KUKA Roboter GmbH, Augsburg, Germany

- 1993 - 1999

- Head of Design and Development at WITTENSTEIN alpha getriebebau GmbH, Igersheim Germany

Management of the design department - 1999 - 2009

- Manager Business Platform Development at WITTENSTEIN, Igersheim, Germany

Management of an interdisciplinary development department, target, human resources and investment planning, responsibility for patents and patent procedures, establishment of innovation and project management - 2009 - 2012

- General Manager WITTENSTEIN alpha GmbH, Igersheim, Germany

Strategic realignment, development of business in Asia, further development of the product portfolio, reorganization and restructuring - 2012 - 2016

- Director Technology Research at WITTENSTEIN, Igersheim, Germany

Management of the international generating process comprised of Business Platform Development, Business Application Processes, Technology Research & Development Technical Standards - since 2016

- Manager Innovation Lab WITTENSTEIN, Igersheim, Germany

Development of disruptive products, processes and business models

Other activities

- since 1996

- Member of the Scientific Advisory Council and longstanding Chairman of the Innovation Management think tank within the German Research Association for Power Transmission (FVA)

- since 2007

- Honorary lecturer at the University of Würzburg, the CDHK at Tongji University in Shanghai and Mosbach University of Cooperative Education, with seminars on innovation management and the theory of inventive problem solving (TRIZ)

- since 2014

- Business Coach (EMCC European Mentoring & Coaching Council)

Publications & Patents

- 221 patents in 71 patent families

Honors & Awards

- 2015

- Winner of the “HERMES AWARD”

- 2016

- Winner of the “Innovation Award of the German Economy”

Dr.-Ing. E. h. Manfred Wittenstein

Dr.-Ing. E. h. Manfred Wittenstein

- Sep. 2, 1942

- Born in Berlin; Germany

- 1963

- Abitur (school leaving examination) at Deutschorden-Gymnasium in Bad Mergentheim, Germany

- 1963 – 1970

- Degree course in Business Engineering at TU Berlin (Berlin Institute of Technology), graduating as Bachelor of Engineering (Dipl.-Ing.)

- 1970 – 1972

- Research assistant at TU Berlin

- 1972 – 1975

- Temporary Head of DEWITTA (for family reasons)

- 1975 – 1983

- Teforma GmbH (manufacturer of plastics thermoforming machines) established

- 1979

- Managing Director of DEWITTA Spezialmaschinenfabrik (now WITTENSTEIN SE) with 50 employees

- 1984

- alpha getriebebau GmbH (today: WITTENSTEIN alpha GmbH) established in cooperation with Manfred Bastian of Bastian oHG

- 1992

- Broadening of the component supplier strategy to become a system provider for electromechanical servo actuators

- 2001

- WITTENSTEIN GmbH & Co. KG turned into a non-listed public limited company

Other activities

- since 1996

- Founder and Director of the WITTENSTEIN Foundation for the promotion of upcoming generations of engineers at the Deutschorden-Gymnasium school in Bad Mergentheim

- since 1998

- Member of the General Assembly of the Heilbronn-Franconia Chamber of Industry and Commerce

- 1998 - 2016

- Board Member of the Research Association for Power Transmission Engineering within the VDMA

- since 1999

- Member of the VDMA Main Board

- 1999 - 2012

- Chairman of the VDMA Research and Innovation Committee

- 1999 - 2013

- Member of the Presidential Board of the Heilbronn-Franconia Chamber of Industry and Commerce

- 2000 - 2012

- Board Member of the BDI / BDA (Confederation of German Employers' Associations) Technology and Innovation Policy Department

- since 2001

- Deputy Chairman of the VDMA Impuls Foundation Managing Committee

- since 2002

- Chairman of the Advisory Board of Bad Mergentheim Campus, Baden-Württemberg Cooperative State University Mosbach

- since 2002

- Member of the University Council of the Baden-Württemberg Cooperative State University Mosbach

- since 2002

- Initiator and principle sponsor of "DEBUT", the Classical Singing Competition

- since 2003

- Member of the Board of Trustees of Fraunhofer IPA

- since 2003

- Sponsor and initiator of the "Creative Young Minds" competition for schoolchildren

- since 2005

- Member of the Advisory Council for the “Deutsche Telekom Stiftung” foundation's Innovation Indicator for Germany

- since 2005

- Member of the Board of Trustees of Fraunhofer ISI

- since 2006

- Member of the Science-Industry

- since 2006

- Member of the Senate of acatech, the German Academy of Science and Engineering

- 2007 - 2010

- President of the German Engineering Federation (VDMA)

- since 2008

- Member of the Advisory Council for Commerzbank's UnternehmerPerspektiven (EntrepreneurialPerspectives) initiative

- 2008 - 2011

- Vice-President of the BDI (German Industry Association)

- since 2009

- Expert in the "Chancellor's Dialogue on Germany's Future", set up to debate how Germans want to live and work in the next decade

- since 2009

- Member of the Fraunhofer-Gesellschaft Senate

- since 2010

- Chairman of the Board of Trustees of Fraunhofer ISI

- 2010 - 2013

- Past President of the German Engineering Federation (VDMA)

- 2010 - 2013

- Member of the "Innovation Dialog" between the German government, industry and science

- since 2011

- Member of the Board of Trustees of the Society for the Promotion of Economic Research (Friends of the Ifo Institute)

- 2012 - 2016

- Member of the Scientific Advisory Council of the Centre for European Economic Research (ZEW)

- 2013 - 2015

- Member of the Industry 4.0 Platform Board of Management

- since 2013

- Member of the Board of Trustees of the Max Planck Institute for Innovation and Competition

- since 2013

- Member of the Board of Trustees of Julius Maximilian University of Würzburg

- since 2015

- Spokesman and Chairman of the Alliance Industry 4.0 Baden-Württemberg Steering Committee

- since 2015

- Member of the Industry 4.0 Platform Steering Committee

Publications & Patents

- since 2004

- Initiator and Advisory Editor of the VDMA Publication "Intelligent Production"

- 2006

- Research and regional production networks – an essential symbiosis? in: J. Geißinger (Editor): Strengthening research, safeguarding

- production

- 2006

- Powering the way to innovation success in: Gleich / Rauen / Russo / Wittenstein (Editors): Promoting innovation management in the capital goods industry

- 2008

- Intralogistics – energy efficient job machine

in: J. Grüneberg / I. G. Wenke (Editors): Labour market in electrical engineering and IT 2008 (16th Edition) - 2009

- Strategy and management profile of WITTENSTEIN AG,

in: Knut Bleicher, Collected Writings – Vol. 3, Normative and strategic management in corporate development

(Editor: Christian Abegglen, Business School St. Gallen, 2009) - 2010

- Germany as a business model – is it now obsolete?,

in: WiSt magazine for study and research, Vol. 39, Issue 8 - 2010

- Germany as a business model. Why globalization is good for us: Dr. Manfred Wittenstein (Editor), Murmann-Verlag, Hamburg

Honors & Awards

- 1997

- Winner of the state of Baden-Württemberg's Business Medal for outstanding services to industry

- 2002

- Winner of the Staufer Medal for special services to the state of Baden-Württemberg

- 2003

- "Pro Ehrenamt" award in the Business category for the promotion of honorary commitment to sports

- 2007

- Honorary Senator of the Baden-Württemberg Cooperative State University Mosbach

- 2008

- Honorary doctorate of engineering (Dr.-Ing. E.h.) from the Faculty of Mechanical Engineering at TU Munich "in recognition of his outstanding achievements and ideas in the research and development of innovative drive systems as well as pioneering corporate governance"

- 2010

- Holder of the Order of Merit of the Federal Republic of Germany (Cross) for "business success and social responsibility"

- 2011

- "Entrepreneur of the Year 2011" in the "Industry" category

- 2012

- German representative in the "World Entrepreneur of the Year 2012" awards and admittance to the Hall of Fame as one of the world's top entrepreneurs

- 2015

- Winner of the "German Mechanical Engineering Prize 2015" for his life's work and the establishment of a culture of innovation throughout the WITTENSTEIN Group

- 2015

- Holder of the Grashof medal of the VDI (Association of German Engineers) for outstanding professional services in the field of science and technology

- 2015

- Member of the Conrad Matschoss Circle of the VDI (Association of German Engineers) as holder of the Grashof medal

Contact

Spokesperson

Dipl.-Ing. (FH) Thomas Bayer

Leiter Innovation Lab

WITTENSTEIN SE

Walter-Wittenstein-Str. 1

97999 Igersheim

Phone: +49 (0) 7931 / 49 31 03 10

E-Mail: thomas.bayer@wittenstein.de

www.wittenstein-galaxie.de

Press

Sabine Maier

Pressesprecherin

WITTENSTEIN SE

Walter-Wittenstein-Str. 1

97999 Igersheim

Phone: +49 (0) 7931 / 49 31 03 99

Fax: +49 (0) 7931 / 49 37 10 399

E-Mail: sabine.maier@wittenstein.de

www.wittenstein.de/de-de/unternehmen/presse/

A description provided by the institutes and companies regarding their nominated projects

Gearboxes are an essential precondition of numerous industrial manufacturing operations; without them, it would be impossible to transmit high forces with the necessary high precision. The drawback: regardless of the gearbox type, only a few teeth at once of the gear wheel engage during power transmission – the majority remain unused. This places limitations on the productivity of machinery, robots and automation systems. The question was therefore “What kind of gearbox is needed to achieve next-generation performance?”.

Dr. Manfred Wittenstein, Thomas Bayer and their team came up with a groundbreaking solution: a radically new gearbox class was born. The innovative heart is the individual teeth which make full surface contact during power transmission.. This novel gearbox design enabled fundamentally better performance. Manfred Wittenstein is Supervisory Board Chairman at the Igersheim firm of WITTENSTEIN SE, where Thomas Bayer works as Manager Innovation Lab.

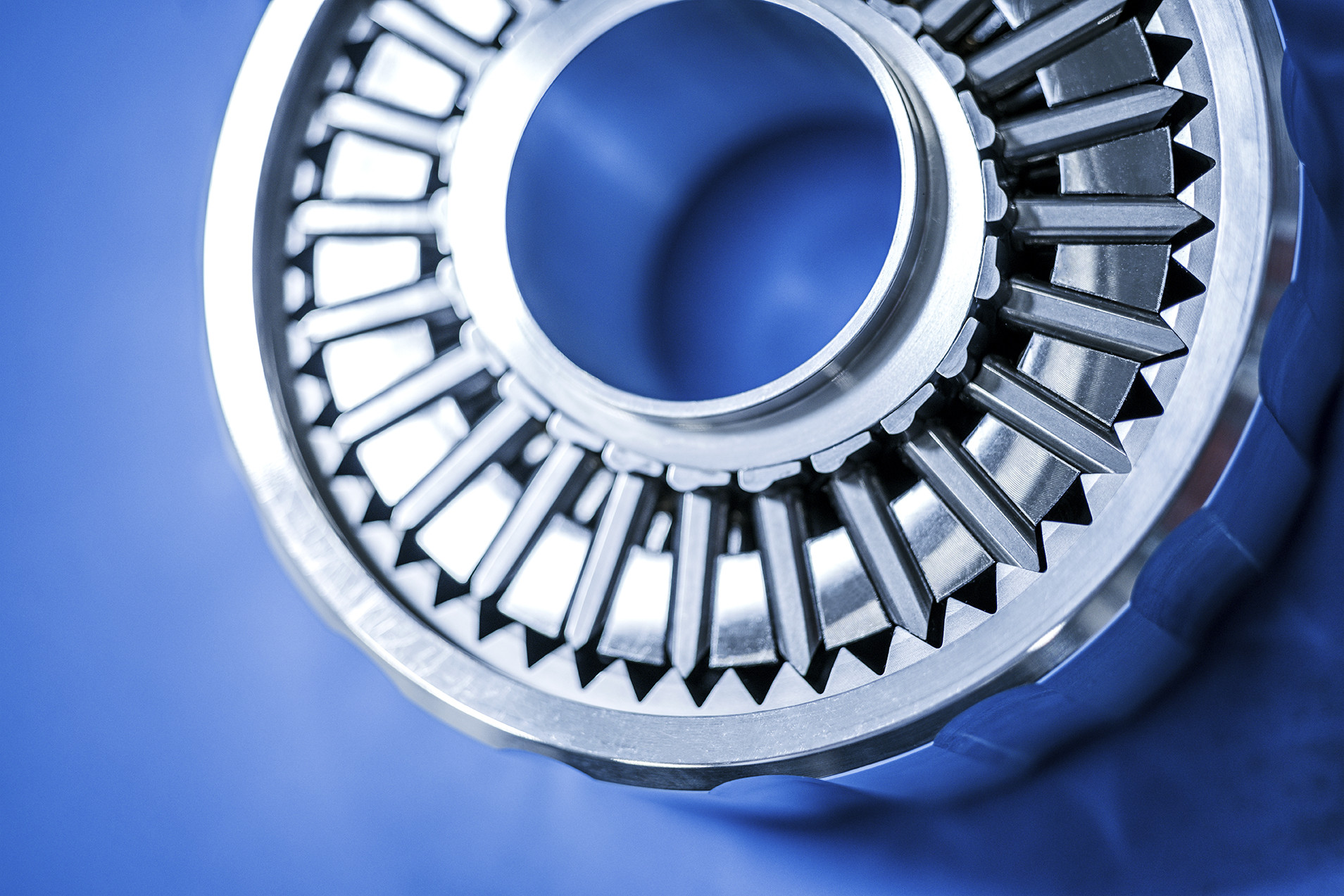

All gearbox types are traditionally based on gear wheels, yet irrespective of the concept they offer only restricted potential for further innovation. What’s more, enhancements of specific performance features are inevitably offset by compromises to one or more other features. To develop a gearbox that is clearly superior in all disciplines, it was necessary to overturn established thinking.

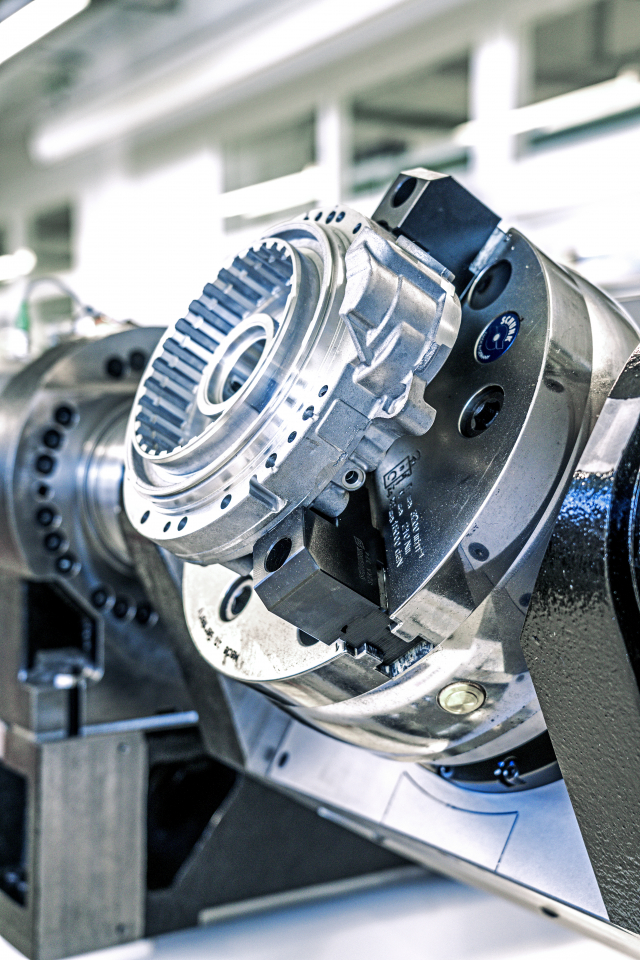

The engineers charged with this task hit on a truly revolutionary idea: to do away with the classic gear wheel as the central gearbox component. In the new gearbox class, the gear wheel is replaced by many individual teeth, an extremely large number of which now engage simultaneously. The inventors modeled these teeth on a logarithmic spiral – a geometric form which also occurs in nature whenever materials and energy are required to be utilized as efficiently as possible. In contrast to conventional gearboxes with gear wheels that make linear contact, power is transmitted by surface contact. The new gearbox has a tooth contact surface which is almost seven times larger than that of a normal planetary gearbox.

The revolutionary concept laid the foundation for improving performance several times over. The new gearbox class beats established gearbox principles hands down in all important technical disciplines. Extreme torque density, torsional rigidity, synchronization and positioning accuracy and absolute freedom from backlash are just a few examples. In short, the gearbox is an enabler for the next generation in mechanical engineering. It is now up to designers and engineers to completely rethink existing machine concepts and realize genuine developmental leaps. They are no longer forced to settle for compromises – for instance, when maximum precision and torque density are specified simultaneously.

Various launching customers have been using the new gearbox for the last few years. Their precision and productivity have been significantly boosted as a result. Machining operations on lathes are much faster, for example, and the service life of the tools is far longer. Unwanted vibration of spline rolling machines has been reduced to a minimum and the machining time is now appreciably shorter. A new five-axis milling machine has been developed with double the usual removal rate.

The potential waiting to be unlocked by the new gearbox class is enormous. For the general market launch, WITTENSTEIN will focus on precision gearboxes for the engineering industry. The demand for these equates to around 9.4 million units worldwide. Plans are already under way for other versions made from plastic. They will mainly be targeted at the consumer goods and automotive industries – for instance, for seat adjusters or electric parking brakes, of which more than 500 million are manufactured per year. Umpteen inquiries have also been received from customers in robotics, the navy, aerospace, renewable energy and e-mobility.

This disruptive innovation was developed entirely in Germany. The new gearbox was honored with the Hermes Award at the Hannover Messe 2015, and it also won the Innovation Award of the German Economy in 2016. A dedicated startup employing some 35 people is presently responsible for development, production and marketing. Yet the impacts on a variety of industrial sectors are infinitely greater. The innovation gives companies a technology lead with clear competitive advantages that protect existing jobs and create new ones.

WITTENSTEIN SE – one with the future

Mit weltweit rund 2.600 Mitarbeitern und einem Umsatz von 385 Mio. € im Geschäftsjahr 2017/18 steht die WITTENSTEIN SE national und international für Innovation, Präzision und Exzellenz in der Welt der mechatronischen Antriebstechnik. Die Unternehmensgruppe umfasst sechs innovative Geschäftsfelder mit jeweils eigenen Tochtergesellschaften: Servogetriebe, Servoantriebssysteme, Medizintechnik, Miniatur-Servoeinheiten, innovative Verzahnungstechnologie, rotative und lineare Aktuatorsysteme, Nanotechnologie sowie Elektronik- und Softwarekomponenten für die Antriebstechnik. Darüber hinaus ist die WITTENSTEIN SE (www.wittenstein.de) mit rund 60 Tochtergesellschaften und Vertretungen in etwa 40 Ländern in allen wichtigen Technologie- und Absatzmärkten der Welt vertreten.

The right to nominate outstanding achievements for the Deutscher Zukunftspreis is incumbent on leading German institutions in science and industry as well as foundations.

The project " A radically new gearbox class – productivity leaps in the engineering industry" was submitted by “Chambers of Commerce and Industry, CCI”.

German President Frank-Walter Steinmeier will award the 22st Deutscher Zukunftspreis for the year 2018 to one of the three nominated teams on November 28, 2018.

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache