Nominee 2008

Energie-Hochleistungsreceiver

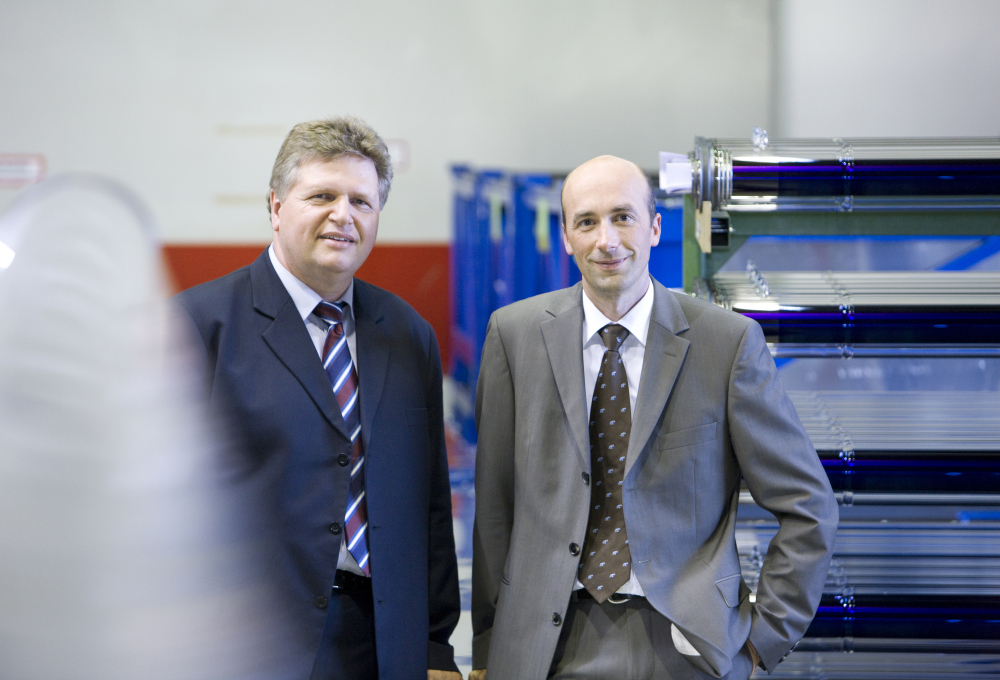

The first step on this road has now been taken by Nikolas Benz and Thomas Kuckelkorn. The nominated researchers developed a receiver for solar power plants that uses a parabolic trough technology to produce electricity from solar radiation much more efficiently than ever before. Nikolas Benz is Managing Director at SCHOTT Solar CSP in Mitterteich; Thomas Kuckelkorn worked as project manager in development from 2001 and 2006 and got the product ready for launch together with Nikolaus Benz.

Oil absorbs solar heat

The sun sends enough energy in the form of sunlight to Earth every hour to meet the energy demands of man for one year. But the technology needed to exploit solar energy and use it to generate power is costly. A less expensive alternative is the parabolic trough system. In these power plants, numerous curved mirrors capture the solar radiation and concentrate it on a receiver, a tube in which heat transfer oil circulates. The temperature of the oil rises due to the bundled radiation and transports heat to a boiler. The heat produces steam that drives a turbine, producing electricity.

more details

Resumes

Dr. rer. nat. Nikolaus Benz

- 25.05.1960

- geboren in München

- 1979

- Abitur

- 1980 – 1987

- Studium der Physik an der Ludwig-Maximilians-Universität, München

- 1987 – 1988

- Diplomarbeit an der Ludwig-Maximilians-Universität, München

- 1989 – 1993

- Promotion in Physik an der Ludwig-Maximilians-Universität, München

Thema: „Direkte solarthermische Prozessdampferzeugung“ - 1993 – 2001

- Wissenschaftlicher Mitarbeiter am Bayerischen Zentrum für Angewandte Energieforschung (ZAE Bayern), Würzburg, Leiter der Gruppe Kollektorentwicklung

- 1999 – 2000

- Forschungsaufenthalte in Slowenien im Rahmen einer Wissenschaftskooperation mit dem dortigen Nationalen Chemieinstitut

- 2001 – 2007

- Entwicklungsleiter im Geschäftsfeld Solar, Schott Rohrglas GmbH, Mitterteich

- 2007

- Übergang in die Schott Solarthermie GmbH, Entwicklungsleiter, Prokura

- seit 2008

- Geschäftsführer der Schott Solar CSP GmbH, Mitterteich

Ehrungen:

- 2004

- Bayerischer Energiepreis, Anerkennung für herausragende innovative Leistungen in der Energietechnik

- 2004

- Schott Visionspreis für marktorientierte Organisation (2. Sieger)

- 2007

- Schott Global Competitiveness Award, Schott Receiver for Nevada Solar One - Build up of new Business Solar Thermal/Receiver

Weitere Tätigkeiten:

- seit 2007

- Vice President der European Solar Thermal Electricity Association (ESTELA), Brüssel, Belgien

Dr.-Ing. Thomas Kuckelkorn

- 26.03.1967

- geboren in Hannover

- 1986

- Abitur

- 1988

- Studienbeginn an der Ludwig-Maximilian-Universität, München

- 1994

- Diplom in Physik, Lehrstuhl für Thermodynamik, Ludwig-Maximilian-Universität, München

- 1995 – 2001

- Wissenschaftlicher Mitarbeiter am Lehrstuhl für Entwerfen und Gebäudetechnik, Prof. Dr. (Univ. Rom) Th. Herzog, Technische Universität München, Projektarbeit im Bereich Solare Gebäudetechnik

- 1999

- Gastwissenschaftler Lawrence Berkeley National Laboratory, San Francisco, USA

- 1998 – 2001

- freiberufliche Tätigkeit als Lichtplaner

- 2002

-

Promotion, Technische Universität München

- 2001 – 2006

- Projektleiter Entwicklung BS Solarthermie, Schott-Rohrglas GmbH, Mitterteich

- 2006

- Leiter Entwicklung Hochtemperatursysteme, BS Solarthermie, Schott-Rohrglas GmbH, Mitterteich

- 2007

- Leiter Produktion Rohmodul, Schott Solar Thin Film GmbH, Jena

Ehrungen:

- 2000

- Bayerischer Energiepreis, Anerkennung (Nichtabbildende Optik für die Tageslichtnutzung)

- 2002

- Promotionspreis, Bund der Freunde der Technischen Universität München

- 2004

- Bayerischer Energiepreis, Anerkennung (Receiver)

Contact

Spokesperson

Dr. rer. nat. Nikolaus Benz

Vice President Developement and Technology

Schott Solar CSP GmbH

Erich-Schott-Straße

95666 Mitterteich

Tel.: +49 (0) 9633 / 80 401

E-Mail: nikolaus.benz@schottsolar.com

Web: www.schottsolar.com

Press

Public Relations Manager

Schott Solar AG

Carl-Zeiss-Straße 4

63755 Alzenau

Tel.: +49 (0) 6023 / 91 18 11

Fax: +49 (0) 6023 / 91 17 00

Mobil: +49 (0) 163 / 68 11 504

E-Mail: lars.waldmann@schottsolar.com

Web: www.schottsolar.de

A description provided by the institutes and companies regarding their nominated projects

Concentrated Solar Energy can supply Entire Cities

In the course of an hour, the Sun sends enough energy to Earth to meet the energy demands of the world’s entire population for a full year, according to calculations by scientists at the Fraunhofer Association. For many years, ways have been sought to exploit this potential energy source on a large scale – among other things with Concentrated Solar Power (CSP) technology. In CSP systems, solar radiation is collected by means of large reflector surfaces – for example, parabolic mirrors, concentrated, and converted into useful energy. Solar power plants with CSP-parabolic trough technology have been used successfully in the USA since the eighties and have produced over 12 terawatt hours of solar power. The breakthrough of this technology worldwide which could make us virtually independent of fossil fuels is possible – to the extent that the systems manage to produce electricity in solar power plants in the medium-term as economically as in conventional power plants. Schott Solar has developed a new generation of highly-efficient receivers that considerably increase the efficiency of solar power plants and thereby make an important contribution to climate-friendly energy generation.

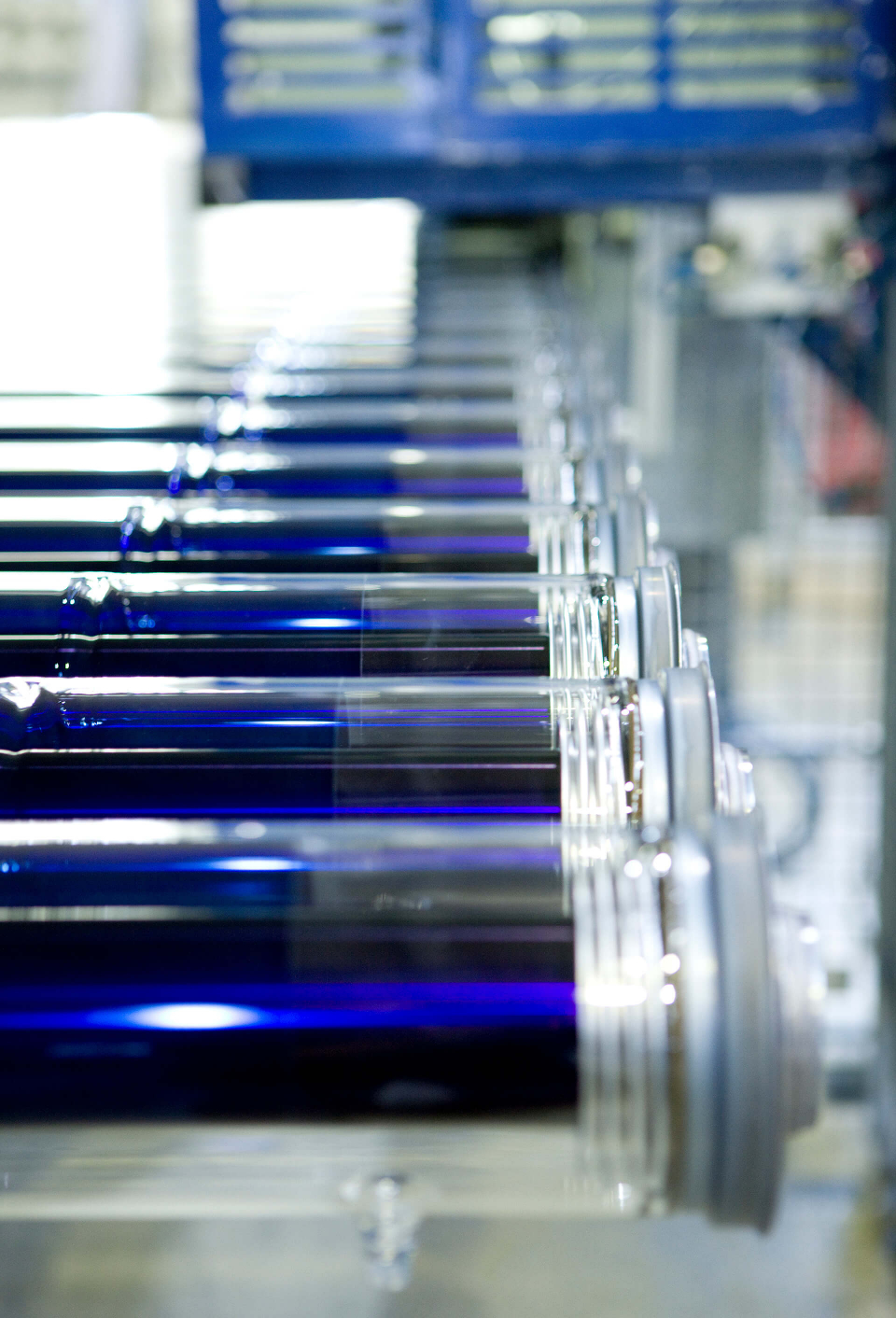

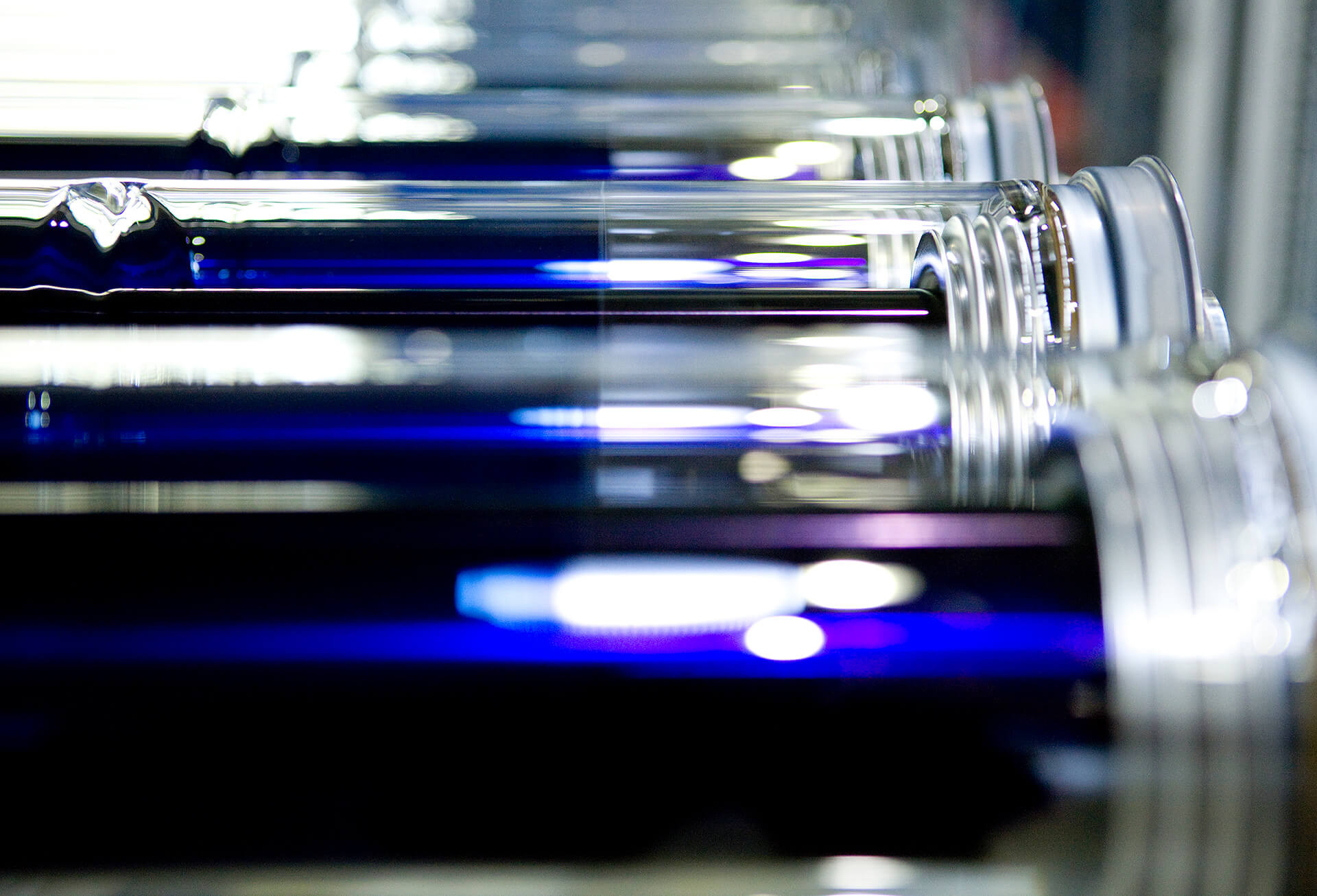

How a Solar Power Plant works

Solar power plants that use parabolic trough technology are basically steam-generating power stations that produce electricity from heat. The major difference compared to conventional power plants is that fossil fuels, such as coal, gas, or oil are not used to supply the energy needed, but rather the sun. In a field of huge curved mirrors, the sun’s radiation is bundled on absorber tubes (receivers). Through the concentrated radiation, the heat transfer medium – an oil that flows through the receiver – is heated to 350 to 400 °C. The hot heat transfer oil is then pumped into the main generating unit. The heat produces steam that in turn drives the plant’s turbines to generate electricity.

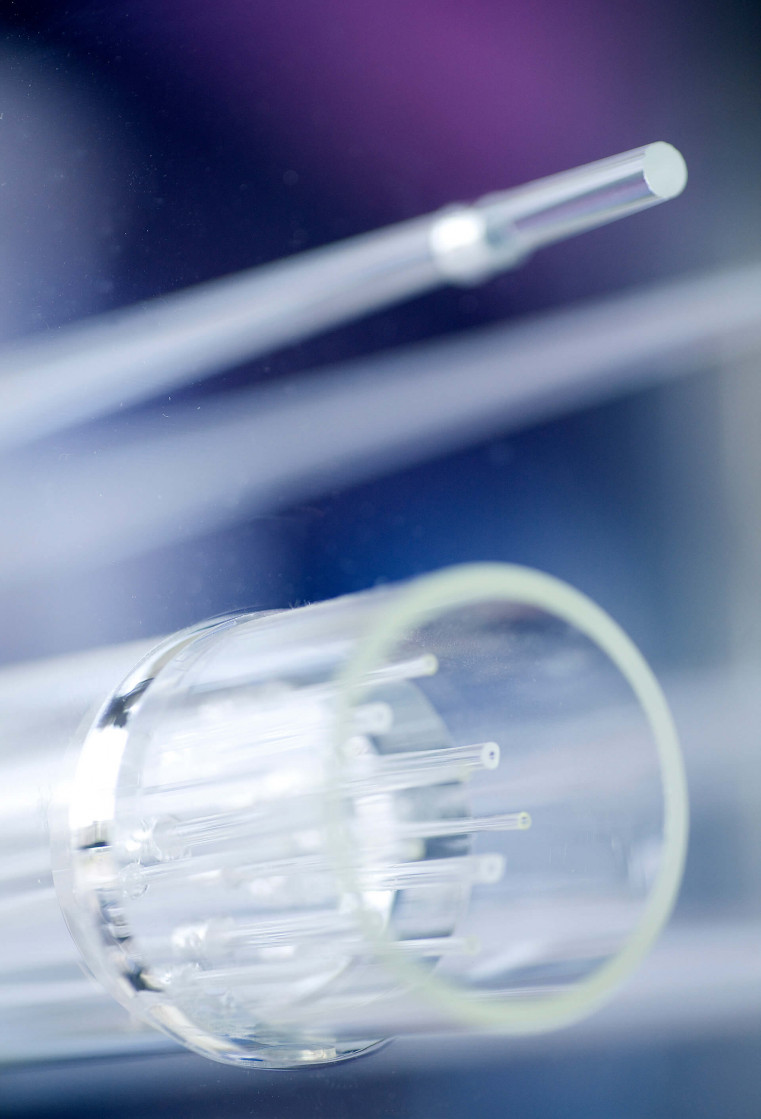

The Key Component of a Solar Power Plant: the Receiver

The receiver is the key component when it comes to the efficiency of a parabolic trough power plant. The better quality the receiver is, the more efficient the power plant. At the same time, it is also one of the most sensitive components in the system because it is subjected to unusual thermal and mechanical loads: the solar radiation is concentrated up to 80-fold and bundled on the receiver’s inner absorber tube. Between the absorber tube and its surrounding sheath a temperature gradient of up to 400°Kelvin is produced on a few millimeters. At the same time, the receiver must convert solar radiation very efficiently so that as little heat as possible is lost. A particular challenge is the long-term stability demanded of the receivers: they should be able to withstand more than 20 years of the most intense solar radiation. The coating of the receiver which is just a few hundred nanometers thick must be able to withstand temperatures of up to 500 °C for this long period. In the past, receivers have failed to fully meet these requirements.

What makes Receivers from Schott Solar so special?

Schott Solar has broken new ground in design and material technology and developed a receiver that is ideally suited with its mechanical and optical properties to the extreme operating conditions in parabolic trough power plants.

Material Technology

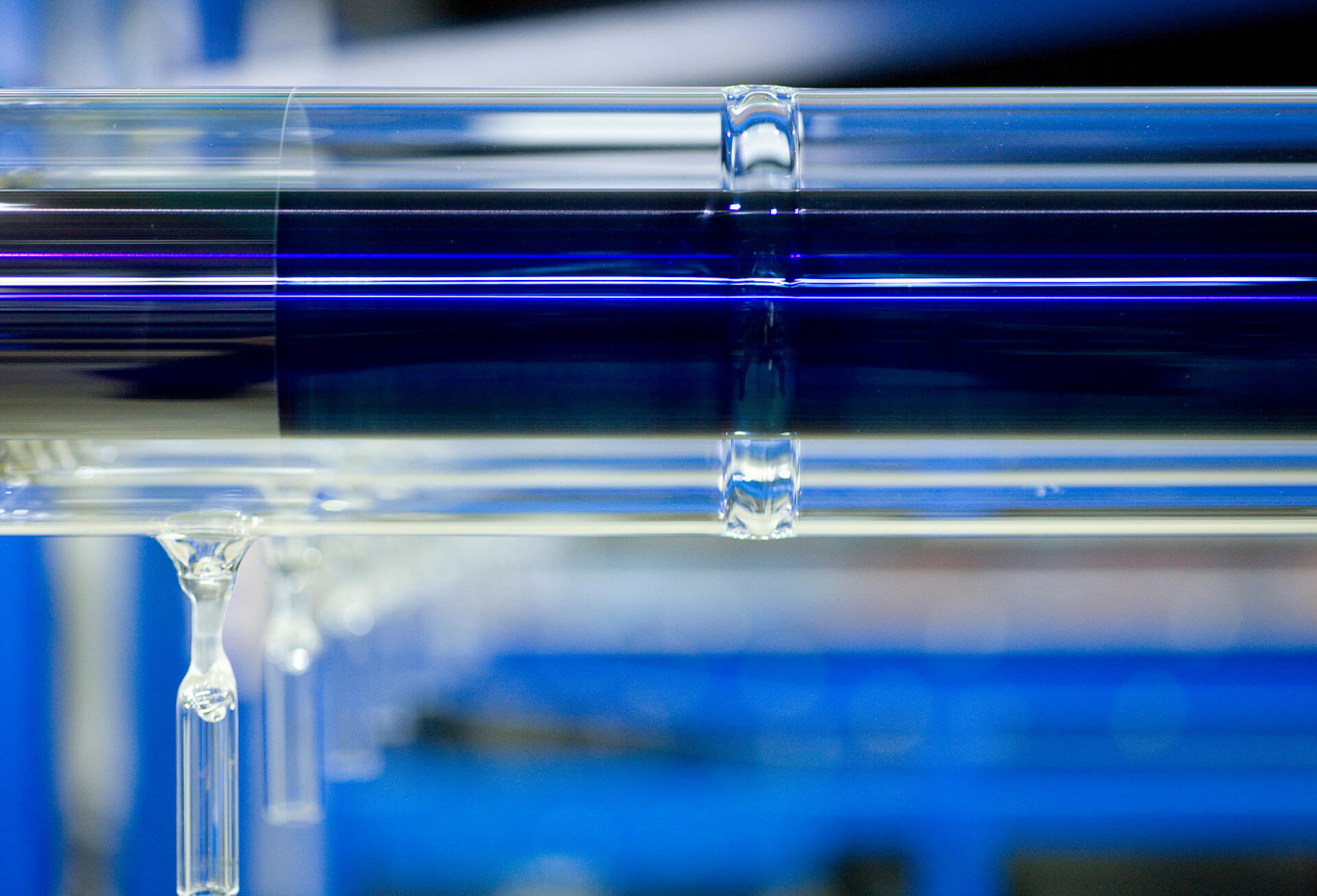

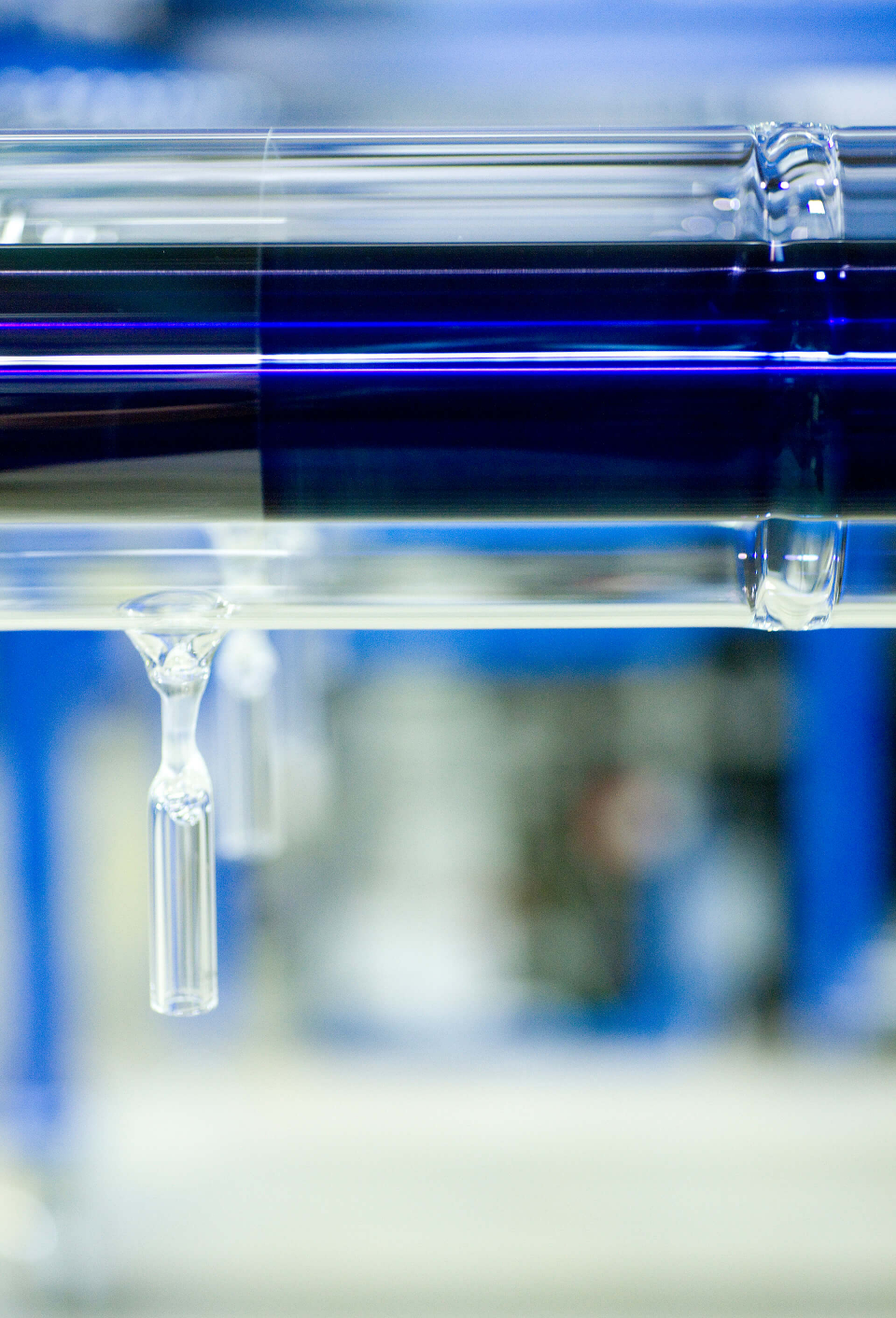

The receivers consist of an absorber tube made of metal that is vacuum-sealed in a glass sheath. To maintain a stable vacuum between glass sheath and absorber tube and thus to minimize heat losses, the permanent glass-and-metal connection is decisive. Since glass and metal expand differently, Schott has developed a special type of glass that has the same coefficient of expansion as metal. The glass-and-metal bond of the two materials is patented and makes the receiver able to permanently withstand the loads placed on it.

Design

Expansion bellows compensate for the different thermal elongation of glass sheath and absorber tube. It connects the two materials in such a way that the thermomechanical load does not become critical even at great differences in temperature. However, the connecting element between cold sheath and hot absorber tube is at risk for wear and damage. In earlier receivers, it was protected by a cover. However, this produced a shadow on the surface of the collector tube which minimized receiver efficiency. Schott Solar has developed innovative transition elements which have a unique stability and are arranged in such a way that around 96 percent of the receiver’s length is actually used.

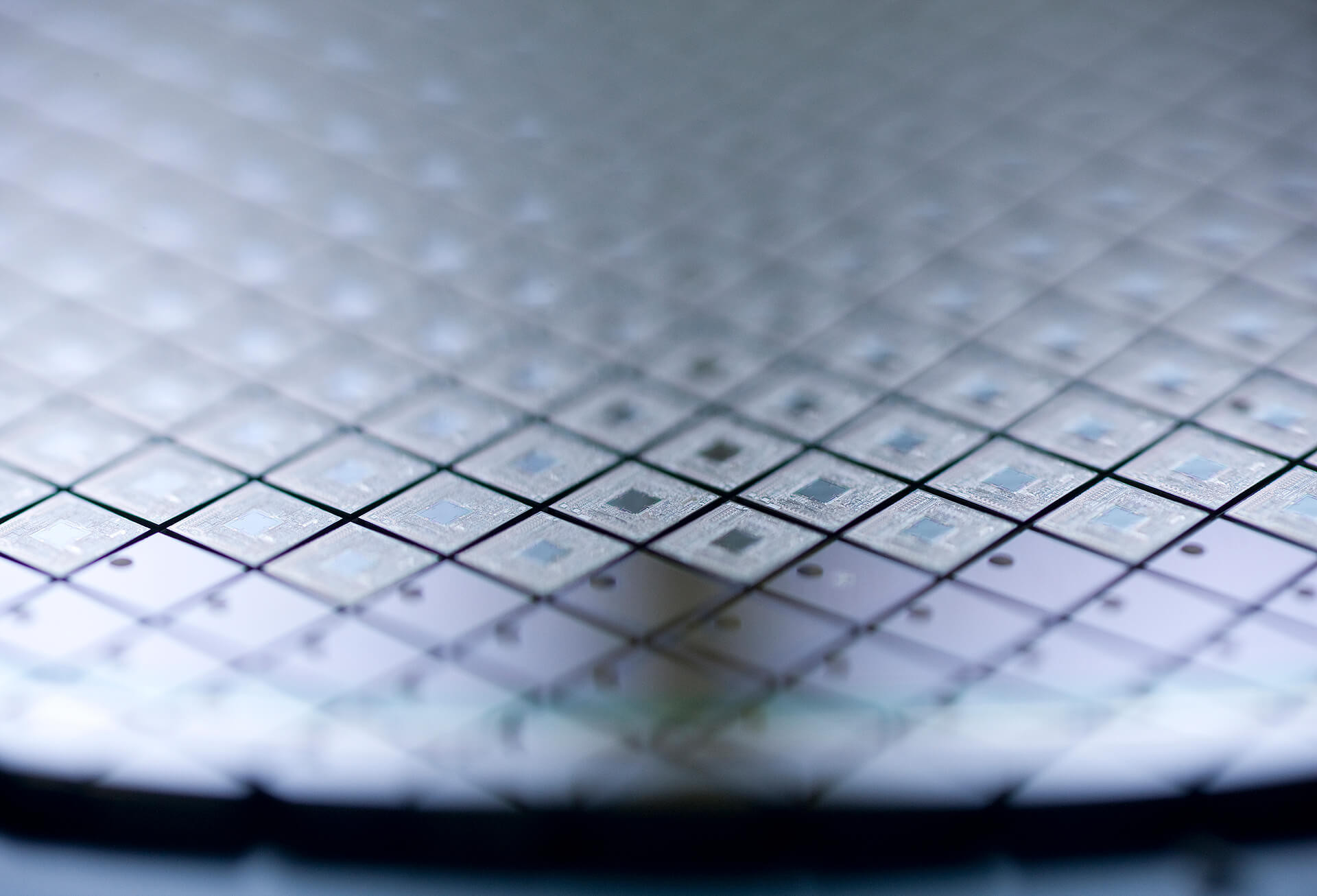

Thin-film Technology

Schott Solar has developed an innovative anti-reflection coating for the receiver’s sheath. It is abrasion resistant and at the same time allows 96 percent of the solar radiation through. The coating is based on nanotechnology. Schott Solar developed the anti-reflection coating together with the Technical University Clausthal-Zellerfeld and converted it into a manufacturing process suited to series production.

The Absorber

The quality of the absorber tube is also decisive for how effectively the solar power plant works. The absorber tube must absorb as much solar radiation as possible and should not emit virtually any heat. In a collaboration of many years with the Fraunhofer Institute for Solar Energy Systems ISE, Schott Solar has developed a highly-selective temperature-resistant absorber coating that further improves the receiver’s performance compared to other known systems. The heat radiation of a receiver heated to 380 °C was able to be reduced to under ten percent. The surrounding sheath is just lukewarm given this low radiation of heat.

New Standards for Solar Power Plants

In a four-year R&D phase, Schott Solar has developed a new product for the marketplace that combines unheard of properties in regard to optical-radiation physics, efficiency, and long-term stability. The company solved all of the technical challenges it faced together with well-known research institutions by applying innovative approaches. The receiver from Schott Solar is setting new standards. The innovative product design provides an important basis for the continued improvement in the performance data of parabolic trough power plants in the future and ultimately for producing electricity in a sustainable and economical way. Due to the high temperature stability and excellent performance data, solar power plant technology can be implemented with higher power efficiency. Future solar installations are either to produce steam directly or use molten salt instead of heat transfer oil as the heat carrier in order to be able to operate the steam process at a minimum of 500 °C and thereby at higher power efficiencies. This would make solar power even more reasonable to produce.

With Solar Energy into the Future

The performance parameters achieved by the Schott Solar receiver are what have made making energy from the Sun ever more economical to exploit. The further development of solar power plants constitutes a genuine alternative to conventional power plants that run on fossil fuels. Approximately 60 solar power plants with a total output of more than three gigawatts are currently in planning or already under construction. They are being built in regions around the world where there is plenty of sunshine – Spain, the USA, and North Africa – and have the potential of providing entire cities with electricity. Solar power plants offer good development opportunities to the economically poorer regions near the sunbelt around the world. These countries frequently lack widespread and stable power supply, yet have great solar radiation – ideal conditions for pushing electrification with solar power plants. A reliable power supply, however, is the key to sustainable development. In the medium- and long-term, solar power plants at these locations could take over some of the electricity production for the industrialized nations.

About Schott Solar

Schott Solar, a wholly-owned subsidiary of the international technology group Schott, produces important components for photovoltaic applications and solar power plants using parabolic trough technology. Schott Solar sees themselves as the market and technology leader in the production of receivers for solar power plants. Schott Solar manufactures in Germany, the Czech Republic, the USA, and in Spain. Schott Solar has over 50 years of experience in innovation and technical competence.

The right to nominate outstanding achievements for the German Future Award is incumbent on leading German institutions in Science and Industry as well as foundations.

The Project “The Heart of Solar Thermal Power Plants: A High-Power Receiver as an Energy Collector” was nominated by the Federation of German Industries (BDI).

Gebärdensprache

Gebärdensprache

Leichte Sprache

Leichte Sprache